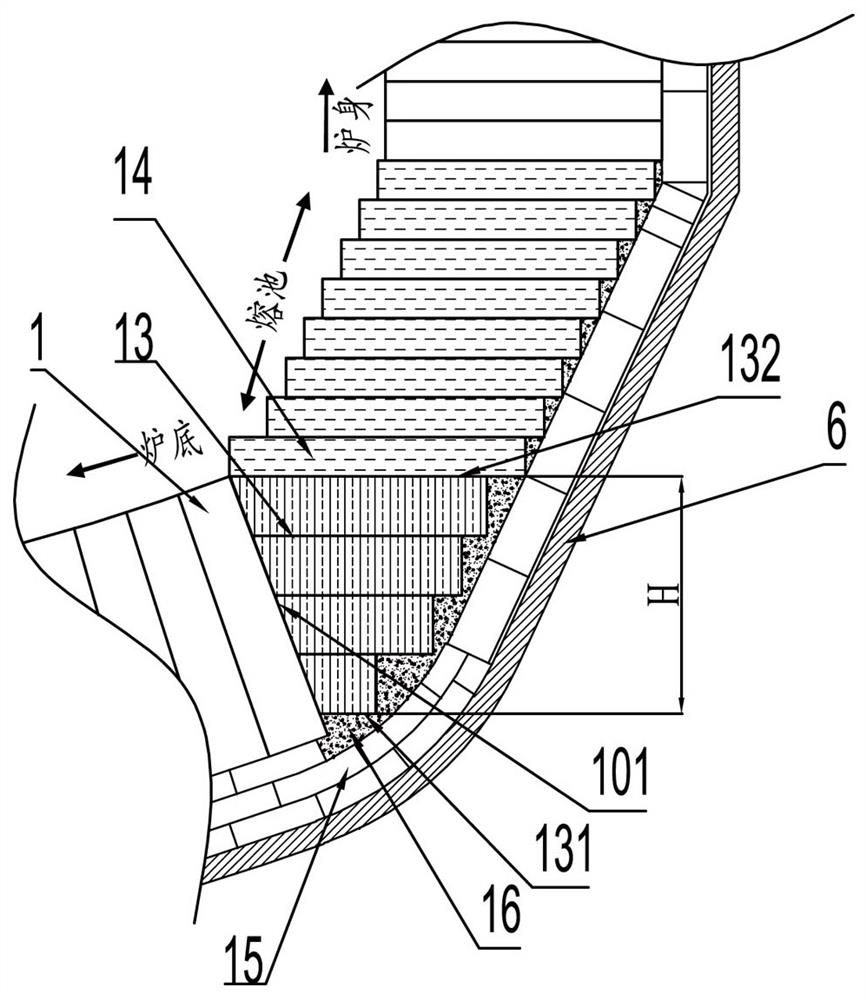

Refractory lining and its masonry method for smelting zone of stress-releasing steelmaking converter

A steelmaking converter and stress release technology, applied in the manufacture of converters, etc., can solve the problems of out of sync expansion effect, damage of refractory lining, large mold management, etc., achieve good thermal stress conduction and release capabilities, improve sealing and Safety, the effect of reducing the cost of production molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1 The present invention is applied to a 210-ton converter of a large domestic iron and steel company

[0086] A large domestic iron and steel company mainly produces SAPH400 series hot-rolled thin plates and 40CrH series alloy bars. In order to reduce the content of inclusions in the steel and improve product quality, the company usually adopts a carbon steel that is much lower than the product carbon when smelting its 210-ton converter. The content standard is used to draw carbon at the end point, and the whole furnace operation is required to maintain bottom blowing and high-intensity stirring, which finally creates the end point temperature is often higher than 1700 °C, the molten steel is overoxidized, the molten steel in the smelting area has a large scour kinetic energy on the furnace lining, and the final slag has strong oxidation. Thin lining slag layer and other harsh conditions that seriously affect the life of the lining. In view of the above smelt...

Embodiment 2

[0092] Embodiment 2 Applying the present invention to a 150-ton converter in a domestic iron and steel company

[0093] The steel company mainly produces Q235 and Q195 series of high-quality carbon structural steel as the main steel types, which belong to the low-carbon steel category. The product forms are mainly ribbed steel bars and high-speed wire rods that are relatively common in the market. In order to improve product quality and production efficiency, the company's 150-ton converter smelting also adopts a bottom blowing intensity that is much higher than the industry average level, so that molten steel in the smelting area has a strong impact on the furnace lining. In addition, due to low-carbon steel smelting requirements, the end point [O] of molten steel is relatively high, the final slag is highly oxidized, and the slag is very thin. Not only is the gradual slag protection effect poor, but it also has abnormal penetration and erosion capabilities for furnace lining ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com