Metal powder treatment system for metal cutting machine

A metal powder and processing system technology, applied in the field of metal powder, can solve the problems of waste of resources, inhalation of workers, rough processing of metal powder, etc., and achieve the effect of improving the recycling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

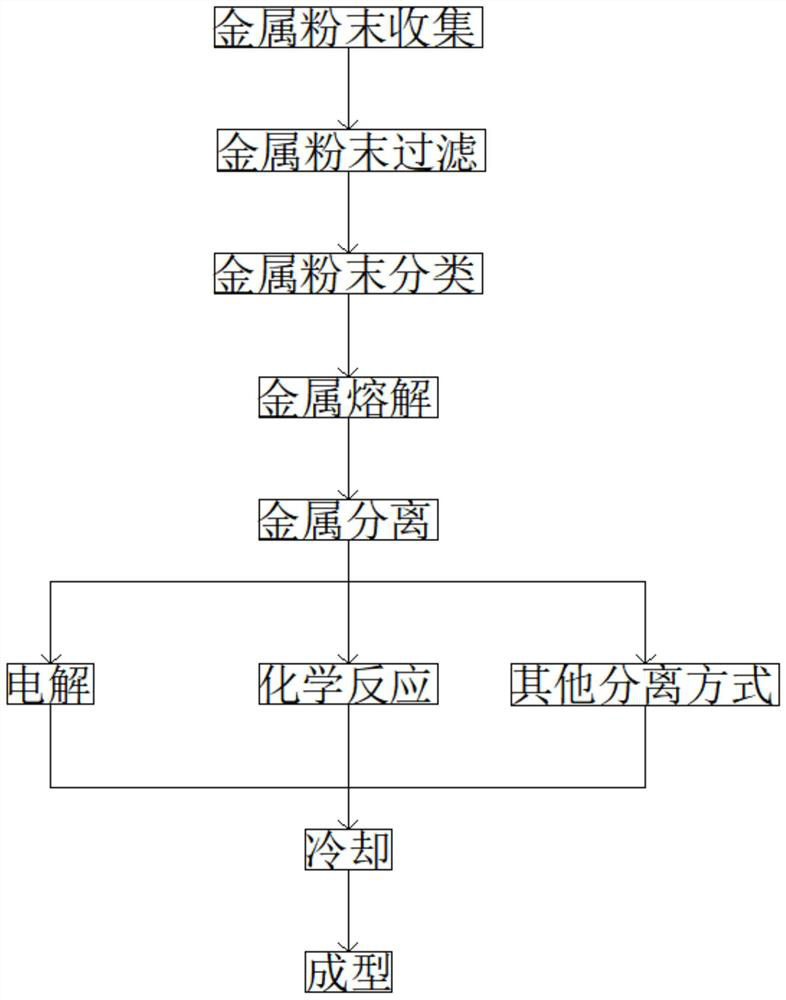

[0019] see figure 1 , the present invention provides a technical solution: a metal powder processing system for a metal cutting machine, including metal powder collection and metal powder filtration, the metal powder is collected through the metal powder to complete the concentration of the metal powder, and the metal powder is filtered and sieved, According to the classification of metal powder produced during metal cutting of different materials, the metal is dissolved to form a liquid, and the liquid metal is separated. The metal separation includes electrolysis, chemical reaction and other separation methods, and the liquid metal is cooled. The final metal forms a solid metal, in which metal powder is produced when the cutting machine cuts the metal, and the powder collector collects the metal powder from the floating metal powder, so that the metal powder is concentrated into piles, and the powder can be collected by electrostatic adsorption. At the same time, it is neces...

specific Embodiment 2

[0021] see figure 1 , the present invention provides a technical solution: a metal powder processing system for a metal cutting machine, including metal powder collection and metal powder filtration, the metal powder is collected through the metal powder to complete the concentration of the metal powder, and the metal powder is filtered and sieved, According to the classification of metal powder produced during metal cutting of different materials, the metal is dissolved to form a liquid, and the liquid metal is separated. The metal separation includes electrolysis, chemical reaction and other separation methods, and the liquid metal is cooled. The final metal forms a solid metal, in which metal powder is produced when the cutting machine cuts the metal, and the powder collector collects the metal powder from the floating metal powder, so that the metal powder is concentrated into piles, and the powder can be collected by electrostatic adsorption. At the same time, it is neces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com