System and method for improving quality of recovered caprolactam and improving recovery process

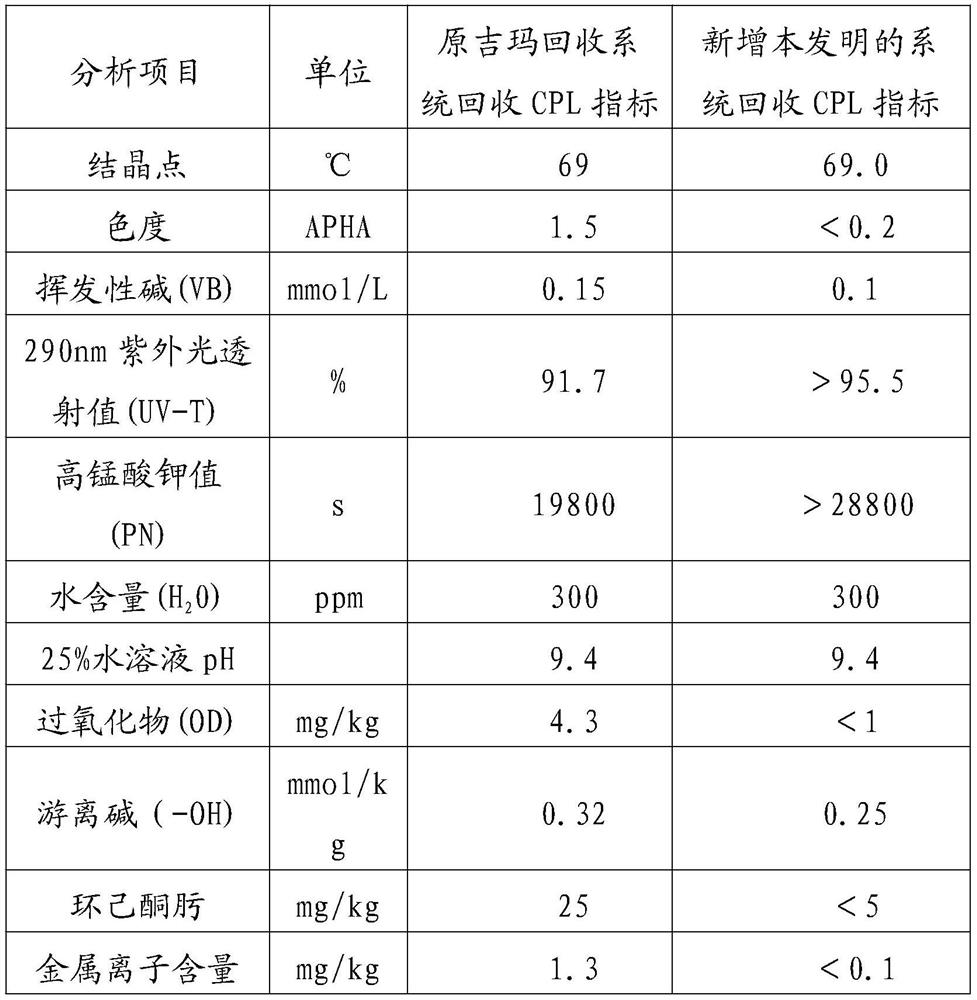

A technology of caprolactam and quality, applied in the field of polymerization, can solve the problems of pre-water removal, rectification pipeline equipment blockage, etc., and achieve the effect of reducing bottom slag, increasing PN value and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

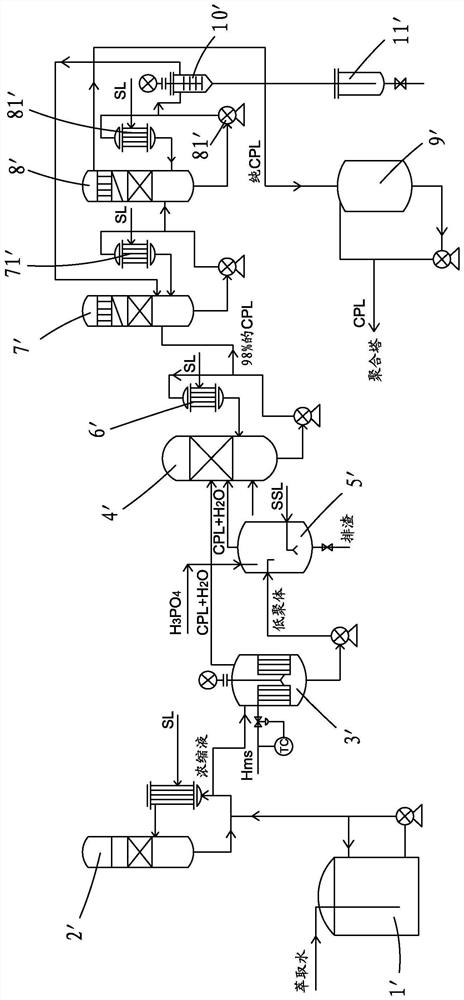

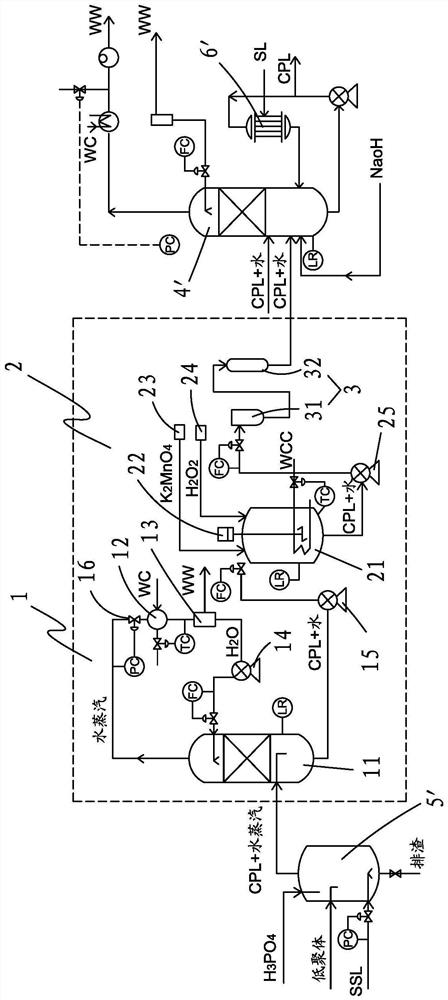

[0043] A system of the present invention that improves the quality of recovered caprolactam and improves the recovery process (each device included in the following equipment is an existing conventional device, and each device is connected by a pipeline to form a corresponding equipment), including (such as figure 2 shown):

[0044] 1. Washing equipment 1, which mainly washes, cools, and collects the depolymerized matter evaporated from the depolymerization tower 5'. This system consists of a washing tower 11 with a spray mechanism, a cooling water heat exchanger 12, and a condensate collection tank 13. It consists of a condensate spray pump 14 and a washing liquid delivery pump 15.

[0045] 2. Chemical treatment equipment 2, which mainly uses potassium permanganate and hydrogen peroxide to oxidize and reduce phosphoric acid and oligomers in the washing liquid. It mainly consists of a temperature-controlled reaction kettle 21, a stirrer 22, a The potassium manganate adding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com