High-strength leather release paper treatment process

A processing technology and release paper technology, applied in special paper, physical treatment paper, fiber raw material processing and other directions, can solve the problems of mechanical strength decline, release paper breaking, etc. Excellent heat resistance and tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

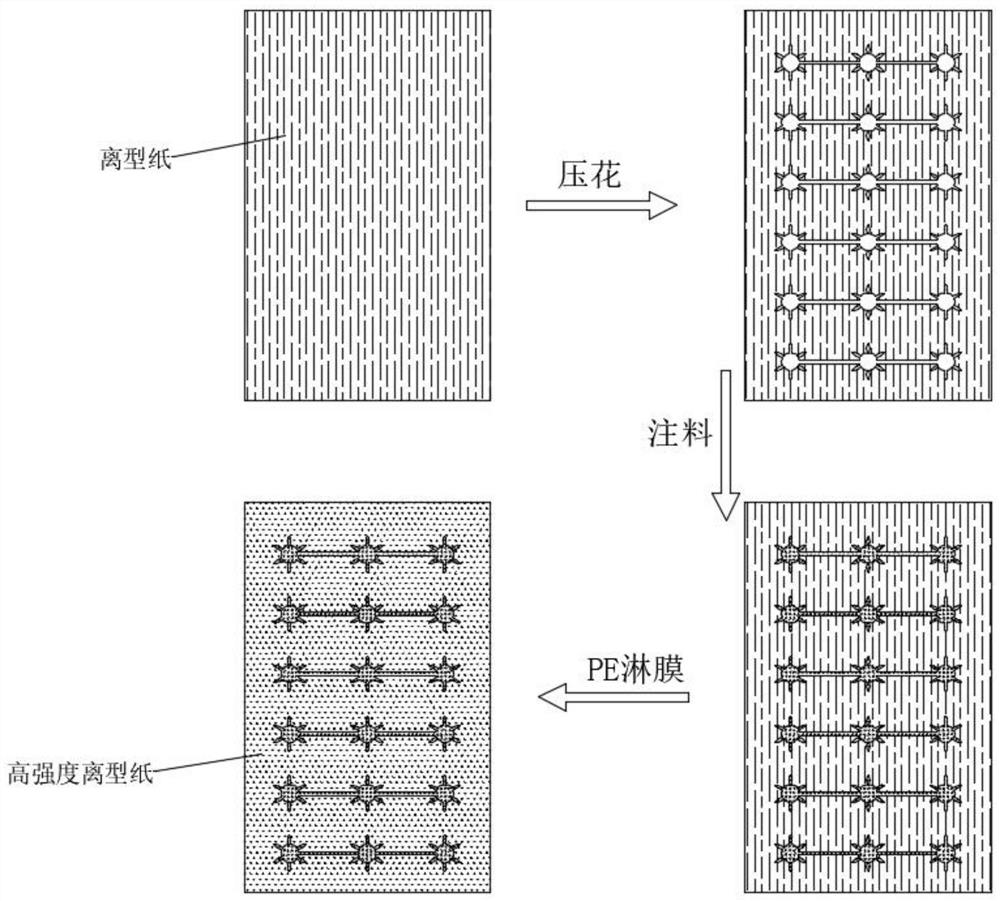

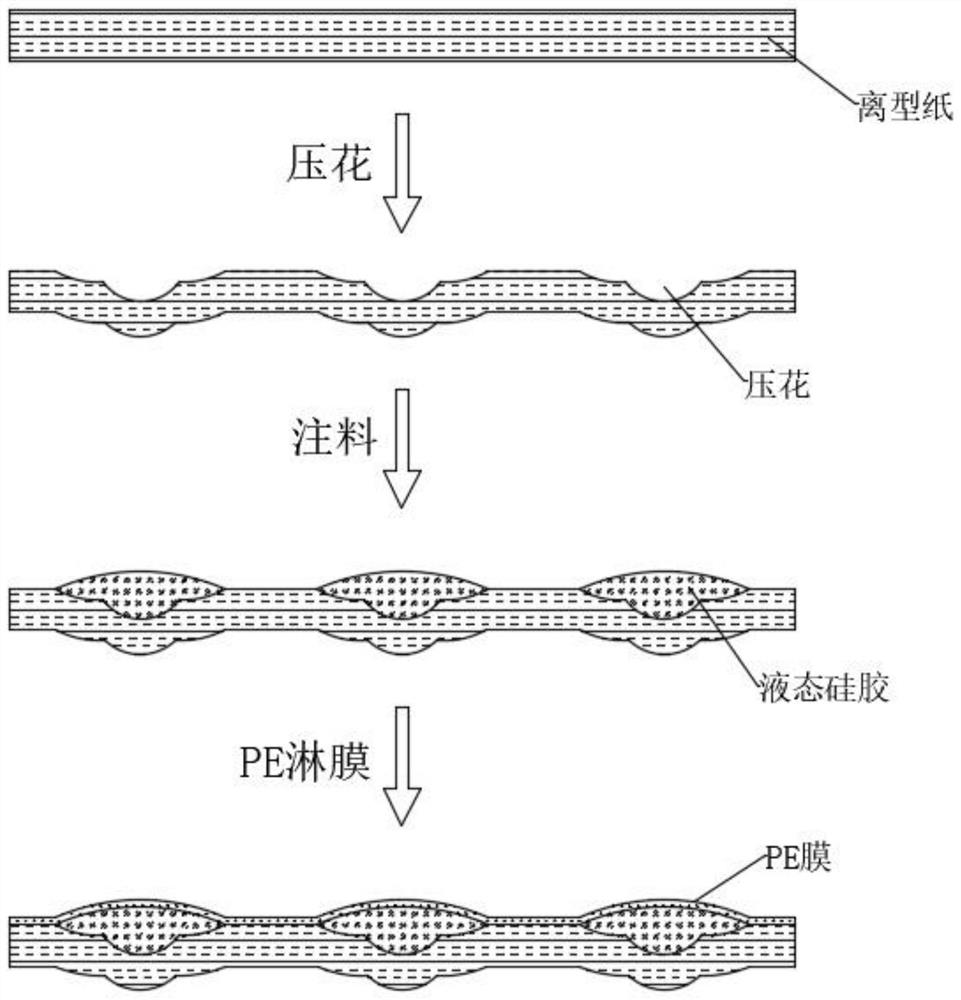

[0050] see Figure 1-9 , a high-strength leather release paper treatment process, see Figure 2-3 and Figure 9 , including the following processing steps:

[0051] S1, first emboss the release paper with an embossing roller, pay attention to the down pressure of the roller during embossing, so as not to crush the release paper, and then conduct random inspection on the release paper after embossing to improve the pass rate of the product;

[0052] Before the embossing in the S1 step, the paper wool pretreatment is carried out to the release paper, and the method for the paper wool pretreatment comprises the following steps:

[0053] S11, first carry out electrostatic treatment on the release paper, and then place the side of the release paper to be embossed downward;

[0054] S12, apply an electric field under the release paper to attract the paper wool, and then use the singeing gun to move back and forth quickly at an appropriate distance below the release paper, thereby...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com