Boiler slag and dust removal equipment

A technology for dust removal equipment and boilers, which is used in the removal of smoke and dust, lighting and heating equipment, and solid separation. , The effect of reducing dust is larger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

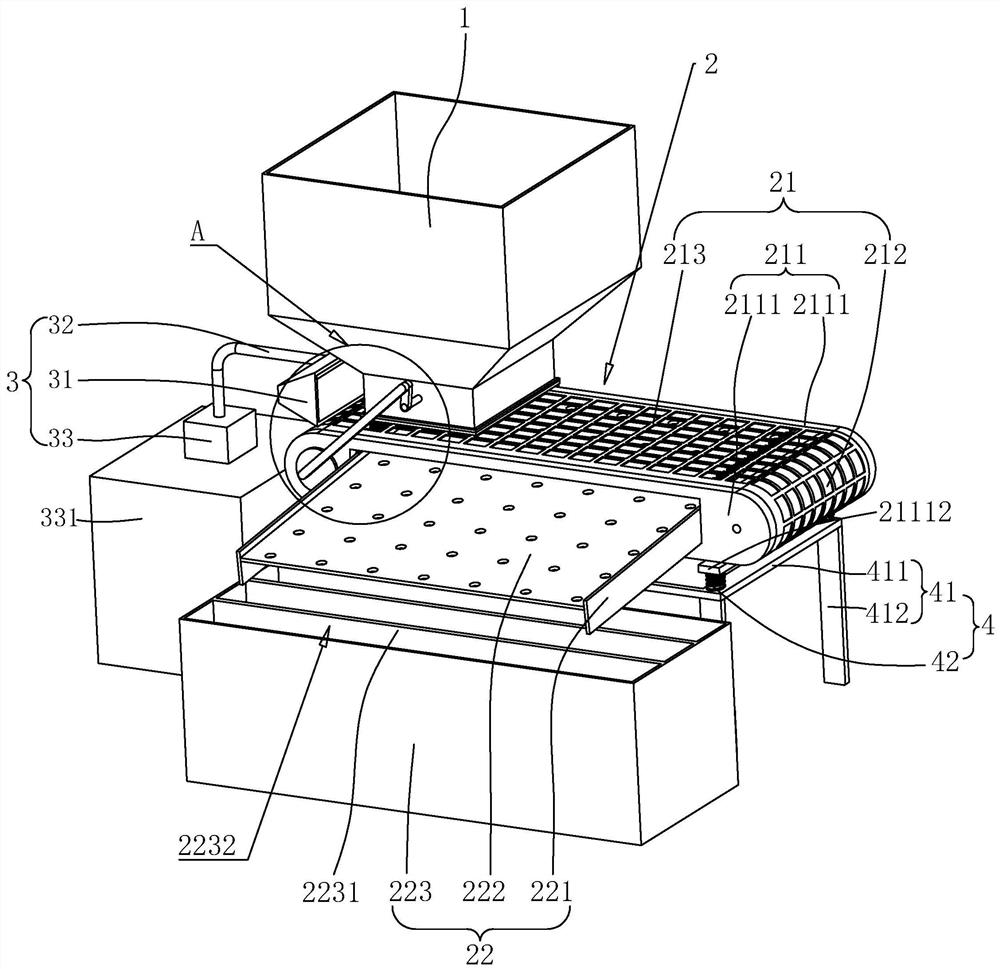

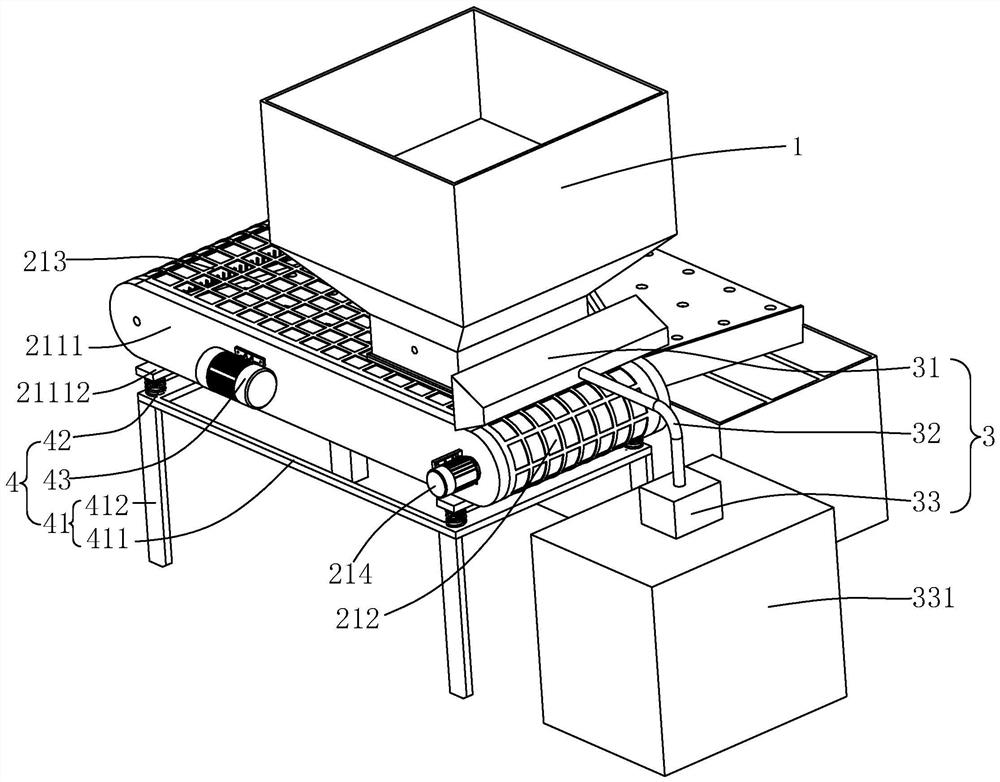

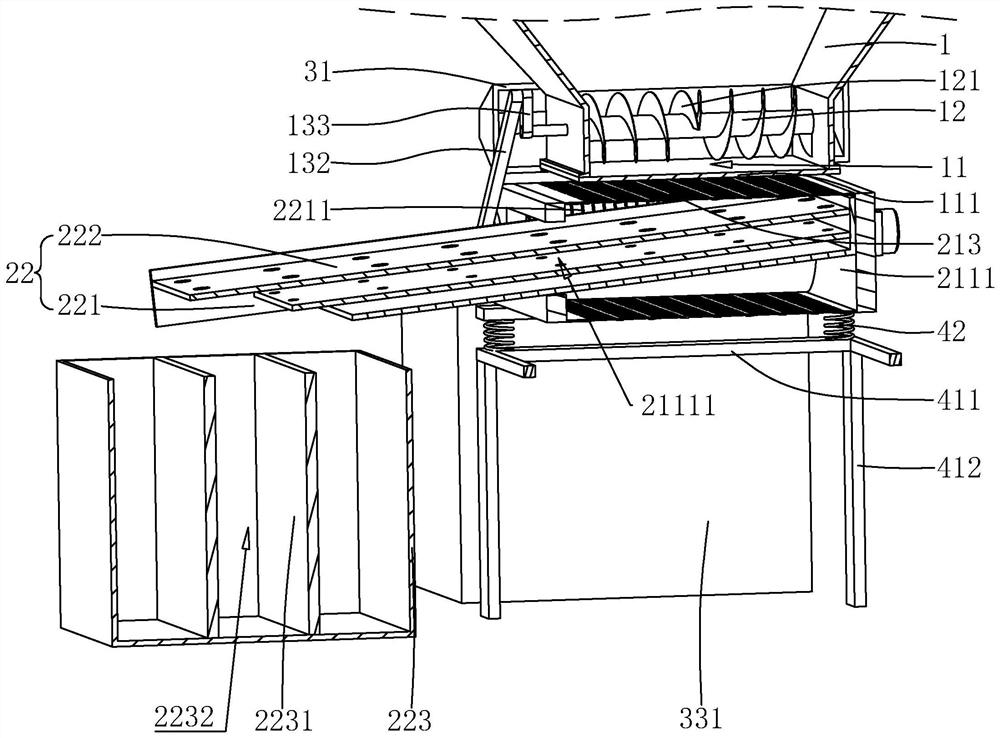

[0034] The following is attached Figure 1-4 The application is described in further detail.

[0035] The embodiment of the present application discloses a boiler slag removal and dust removal equipment. refer to figure 1 and figure 2 , A boiler slag removal and dust removal equipment includes a boiler body 1 , a transport assembly 2 , a dust removal assembly 3 and a vibration assembly 4 .

[0036] refer to figure 1 , figure 2 and image 3, the bottom of the boiler body 1 is provided with a slag removal port 11, and the slag removal port 11 is fixedly connected with a baffle 111 by screws, and the baffle 111 seals the slag removal port 11, and the transport assembly 2 includes a conveying part 21 and a screening part 22. Part 21 includes conveying frame 211, conveying roller 212, conveying belt 213 and conveying motor 214. The boiler body 1 is located directly above one end of conveying frame 211. Conveying frame 211 includes two mounting plates 2111 arranged in parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com