Novel finned coil pipe

A fin coil and fin technology is applied in the field of thermal energy equipment, which can solve the problems of unbalanced heat absorption and heat exchange, large pitch of fin straight tubes, and compact volume of the body that cannot be heated, saving space and reducing welding. Joints, the effect of reducing the risk of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

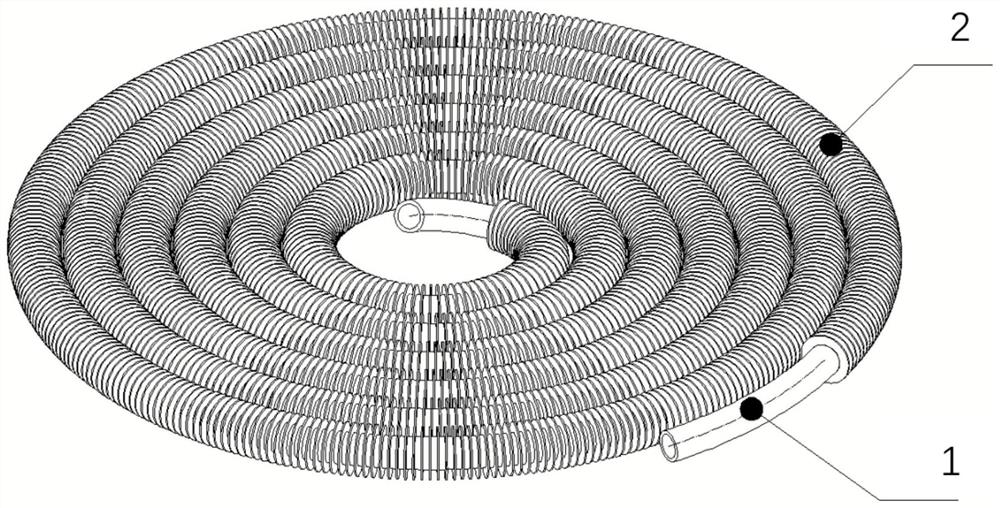

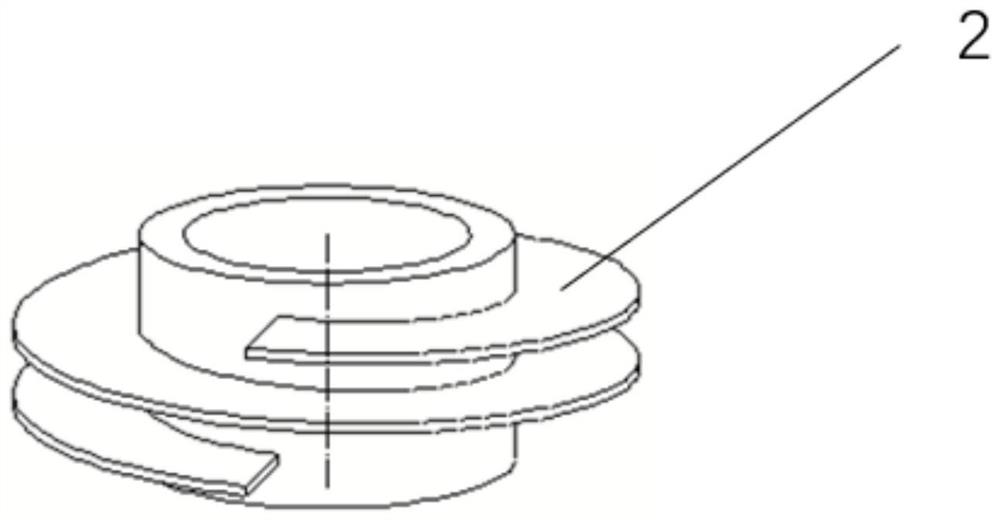

[0025] A new type of finned coil in this embodiment has a structure such as figure 1 As shown, it includes a base tube 1 and fins 2 spirally wound on the base tube 1 , and the base tube 1 and the fins 2 are integrally formed by laser welding. The base tube 1 is bent and coiled along a spiral to form a flat disk, and the fins 2 are as figure 2 The winding sheets shown are continuously helically wound on the outer wall of the base pipe 1, and then bent and coiled together with the base pipe 1 to form a plane disk shape. There are no fins 2 on both sides of the base pipe 1, which form the joints of the light pipe. During installation, only the joints at both ends of the base pipe 1 need to be connected to complete the installation of the coil, which reduces the number of welded joints and greatly reduces the Risk of water leakage.

[0026] After the base tube 1 is coiled, each circle of the base tube will stick to the base tube of its inner or outer ring, and the fins of the b...

Embodiment 2

[0030] A new type of fin coil in this embodiment differs from Embodiment 1 in that:

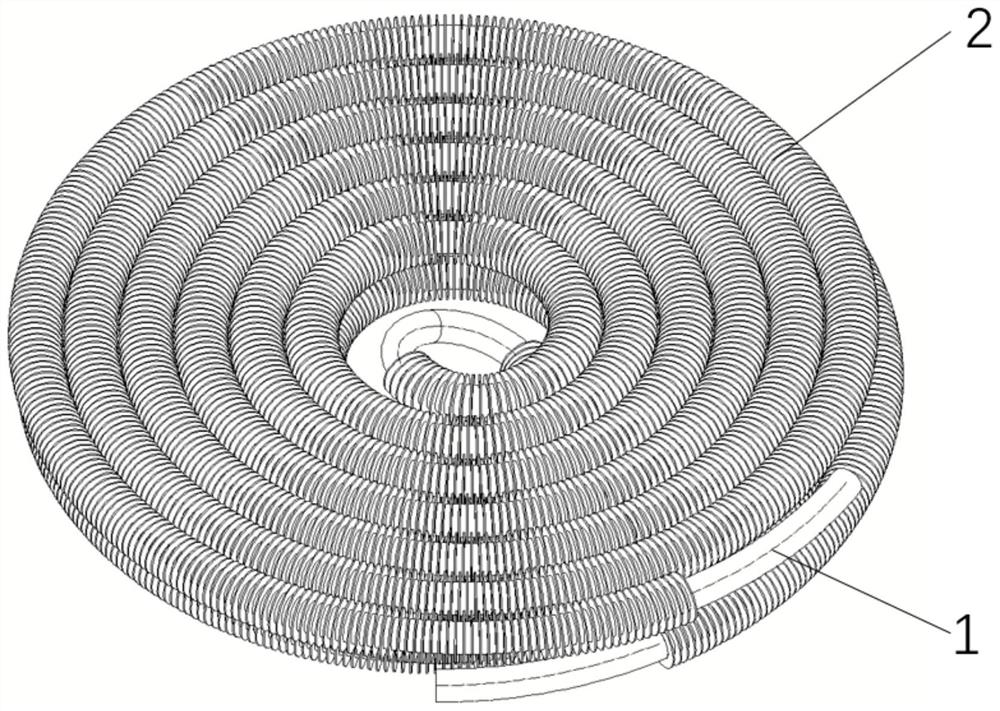

[0031] Its structure is as image 3 As shown, there are two base pipes 1, and the two layers of base pipes 1 are stacked up and down, and the joints in the middle are connected to each other to form a double-layer coil, and the upper and lower layers respectively have a joint at one end of the original base pipe. part, so that the internal heat exchange medium can flow in from one end of one base pipe and flow out from the other end joint of the other base pipe.

[0032] On the basis of this again, multi-layer base pipes can still be stacked, and only one of the joints needs to be connected with other base pipes in sequence to obtain a multi-layer coil with higher heat exchange capacity.

[0033] Other structures can refer to Embodiment 1.

Embodiment 3

[0035] A new type of fin coil in this embodiment differs from Embodiment 1 in that:

[0036] Fins such as Figure 4 As shown, there are continuous sawtooth-shaped gaps on its periphery, which can further improve the heat exchange capacity.

[0037] Other structures can have reference embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com