Hydrophobic alginic acid particle group and method for producing same

A technology of alginic acid and hydrophobicity, which is applied in the direction of alginic acid coatings, pharmaceutical formulations, and cosmetic preparations, etc., which can solve the problems of performance degradation, discomfort, and poor compatibility, and achieve less foreign matter, excellent tactility, and high The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0140] [Example 1-1] Production of Particle Group A1

[0141] Each component shown below was put into a 2,000 mL flask, and it stirred for 1 hour using the stirrer, and was made to disperse|distribute.

[0142] Calcium Alginate Spherical Beads 194.0g

[0143] (manufactured by Nisshinbo Chemical Co., Ltd.: brand name Fravikafine, MV=20 μm)

[0144] Ion-exchanged water 735.0g

[0145] Ethanol 315.0g

[0146] Sodium laurate 6.0g

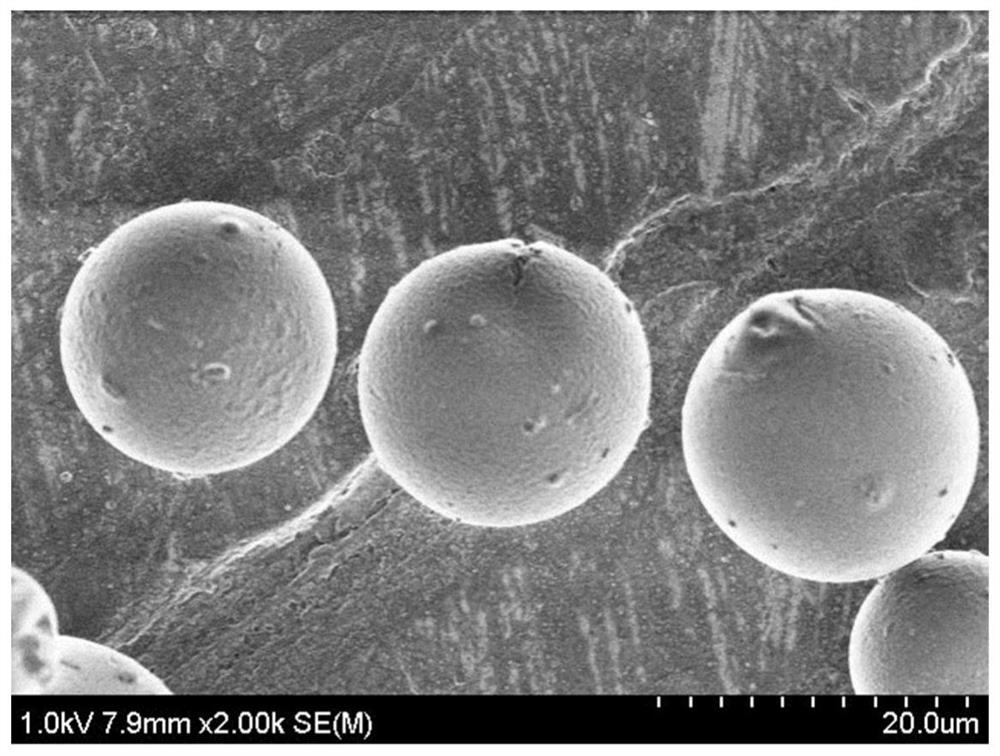

[0147] Next, after heating slowly in an oil bath at 95° C. for 2 hours, the solvent was removed by distillation, and the reaction solution was concentrated while performing surface treatment to perform a hydrophobizing treatment. After cooling, it was repeatedly centrifuged and washed with ion-exchanged water to finally prepare a 10% by mass aqueous dispersion. This dispersion liquid was spray-dried using a spray dryer (hot air temperature: 220° C.), and the target particle group A1 was obtained. The particle group A1 was observed with a scanning ...

Embodiment 1-2

[0148] [Example 1-2] Production of Particle Group A2

[0149] Each component shown below was charged in a 5,000 mL heatable container, and dispersed using a mixer.

[0150] Sodium alginate 313.6g

[0151] (manufactured by Kimika Corporation: trade name Kimika Algin ULV-L3 (40 mPa·s, 10% by mass aqueous solution))

[0152] Ion exchanged water 4260.0g

[0153] Sodium Stearoyl Glutamate 6.4g

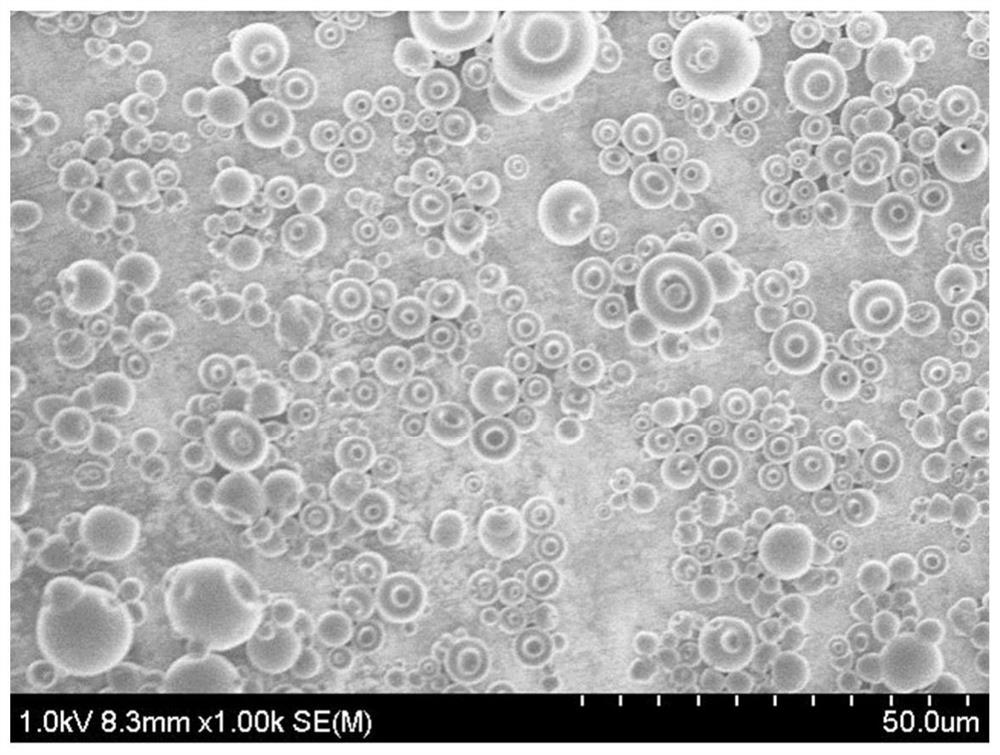

[0154] Thereafter, it was heated to 60°C and dissolved over 2 hours to prepare a 7.0% by mass aqueous solution. Next, the above-mentioned aqueous solution was spray-dried using a spray dryer (hot air temperature: 200° C.) to obtain particle groups. The shape of the obtained particle group was observed by SEM, and it was found to be flat particles having depressions, and it was a monodisperse particle group with an MV of 7 μm in the particle size distribution.

[0155] Put 300.0 g of the obtained particle group into 300.0 g of ethanol and stir to make a 50.0% by mass ethanol dispersion,...

Embodiment 1-3

[0157] [Example 1-3] Production of Particle Group A3

[0158] Each component shown below was put into a 5,000 mL heatable container, and it stirred for 5 minutes using the homogenizer (T25 by IKA company), and it emulsified.

[0159]

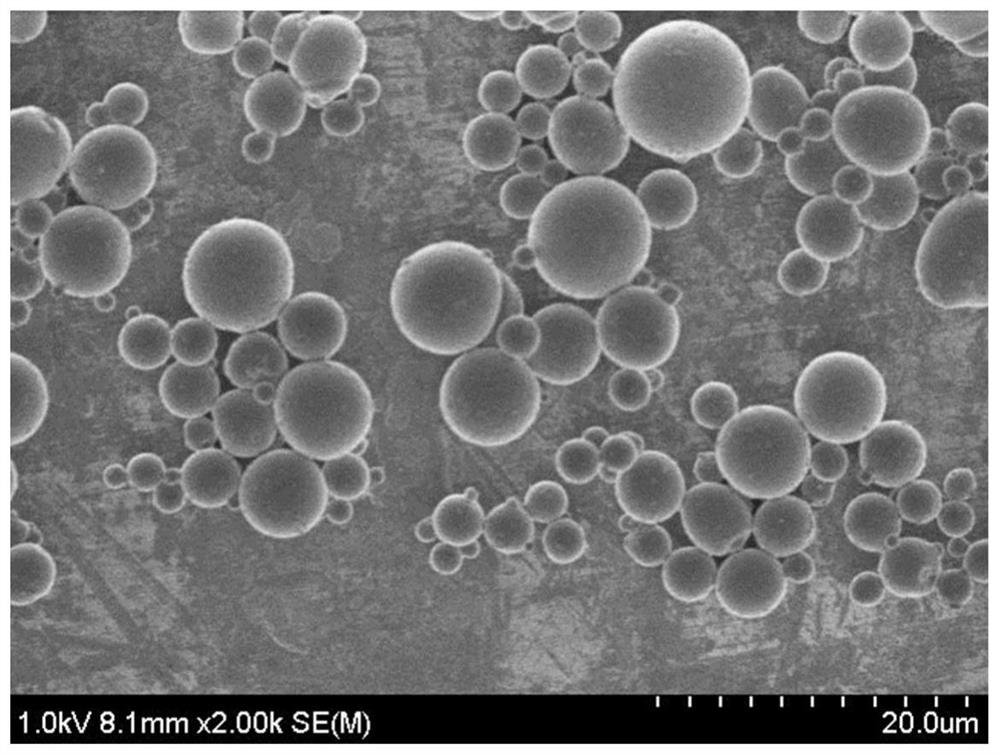

[0160] A 15.0% by mass calcium chloride aqueous solution was dropped there, and stirring was performed at 50° C. for 2 hours after completion of the dropping. After stirring, it was cooled, centrifuged and washed repeatedly with ethanol and ion-exchanged water, and vacuum-dried to obtain particle groups. The obtained particle group was observed by SEM, and the shape was confirmed, and it turned out that it was a spherical particle. In addition, the result of the particle size distribution measurement: it is a monodisperse calcium alginate particle group (hereinafter also referred to as calcium alginate particle group A.) with an MV of 10 μm.

[0161] Next, each component shown below was put into a 2,000 mL flask, and it stirred for 1 hour u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com