Transmission system of corn husker

A transmission system and peeling machine technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of poor configuration of corn harvesters, large power transmission stages, and high manufacturing costs, so as to improve transmission efficiency and reliability performance, high reliability, and simple layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments, and it should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention.

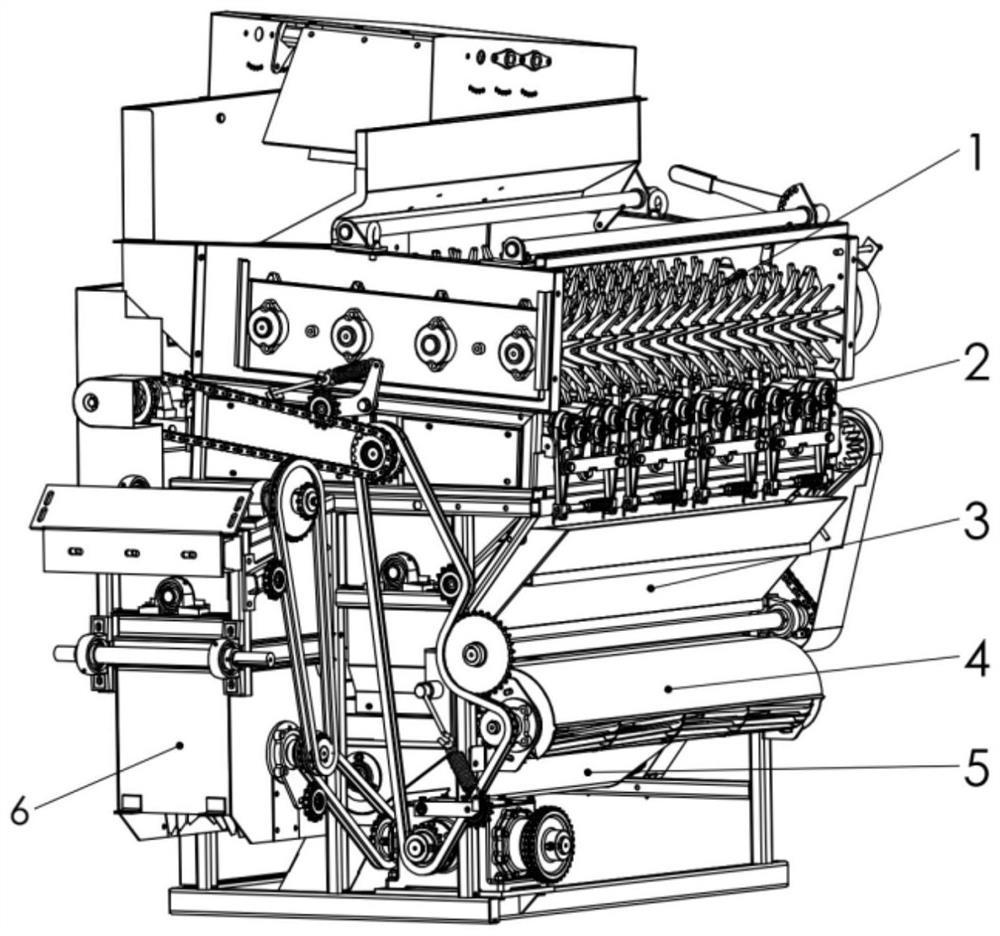

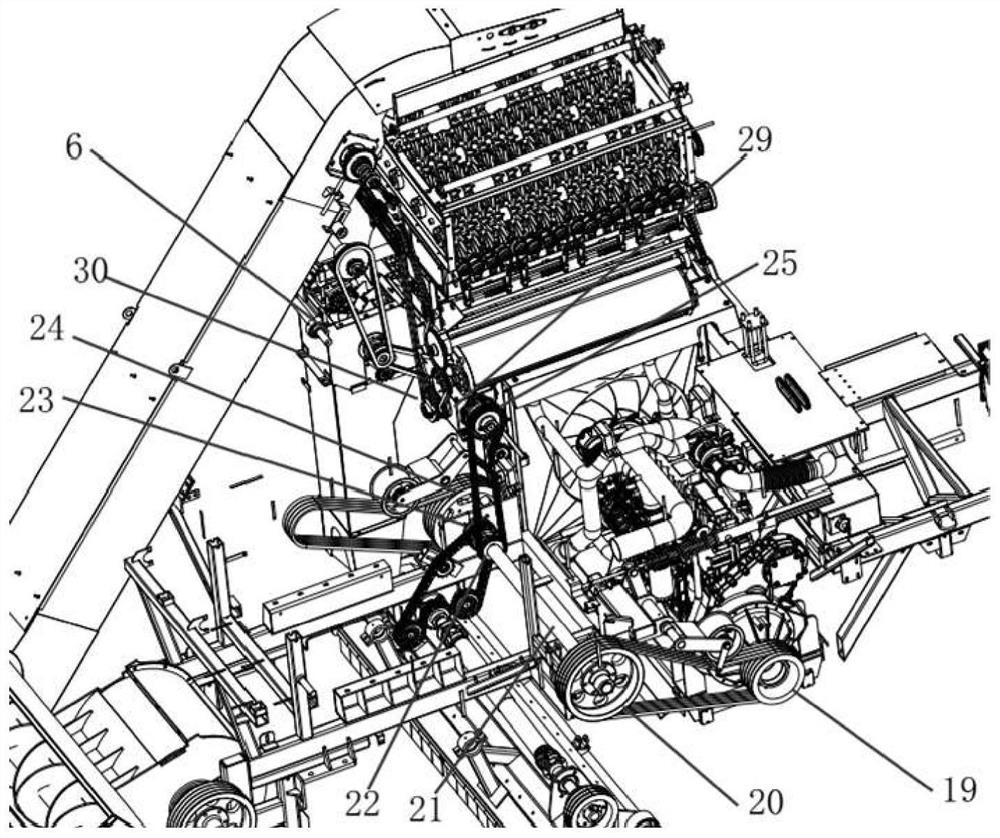

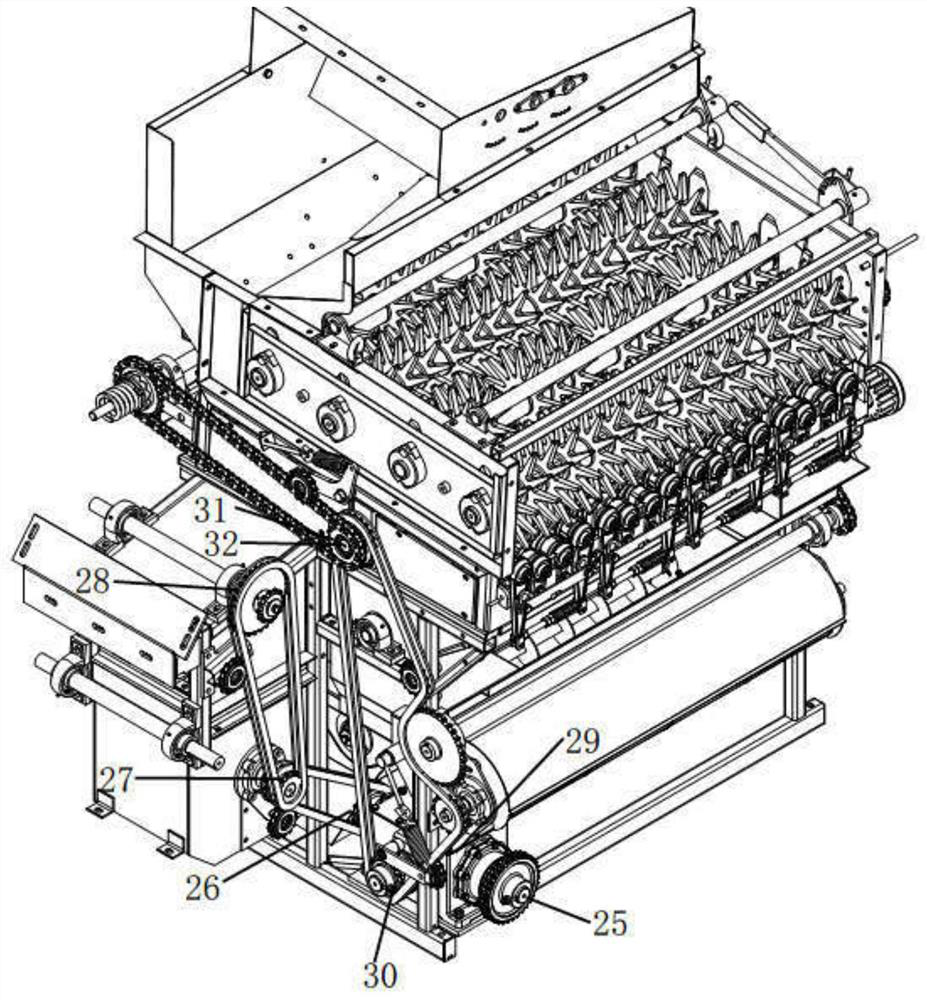

[0028] Such as Figure 1-7 As shown, a corn peeling machine transmission system includes a pressure feeder assembly 1, a peeling assembly 2, an ear cleaning assembly 3, a grain cleaning fan 4, a grain recovery device 5, a flour peeling machine 6 and a main drive shaft 21.

[0029] Described peeling assembly 2 comprises several peeling units, and described peeling unit comprises two outer peeling rollers that are arranged in parallel and two inner peeling rollers that are arranged in parallel between two outer peeling rollers, and the specifically peeling unit setting mode is prior art, here I won't repeat them here.

[0030] The pressure feeder assembly 1 includes several pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com