Efficient moisture-proof and dust-removing device for electronic components

A technology for electronic components and dust removal devices, which is used in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc., can solve the problems of inability to adjust the space, waste of space desiccant, failure and damage of electronic components, etc. Achieve refined utilization, avoid waste, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further illustrated by the following examples.

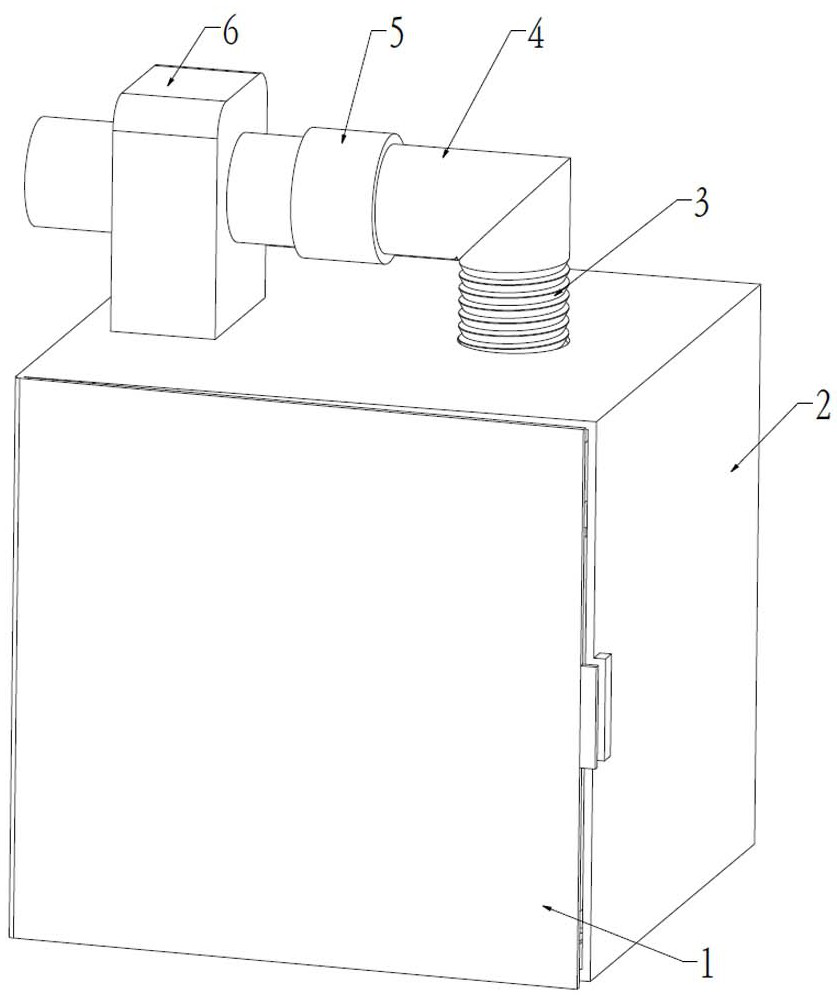

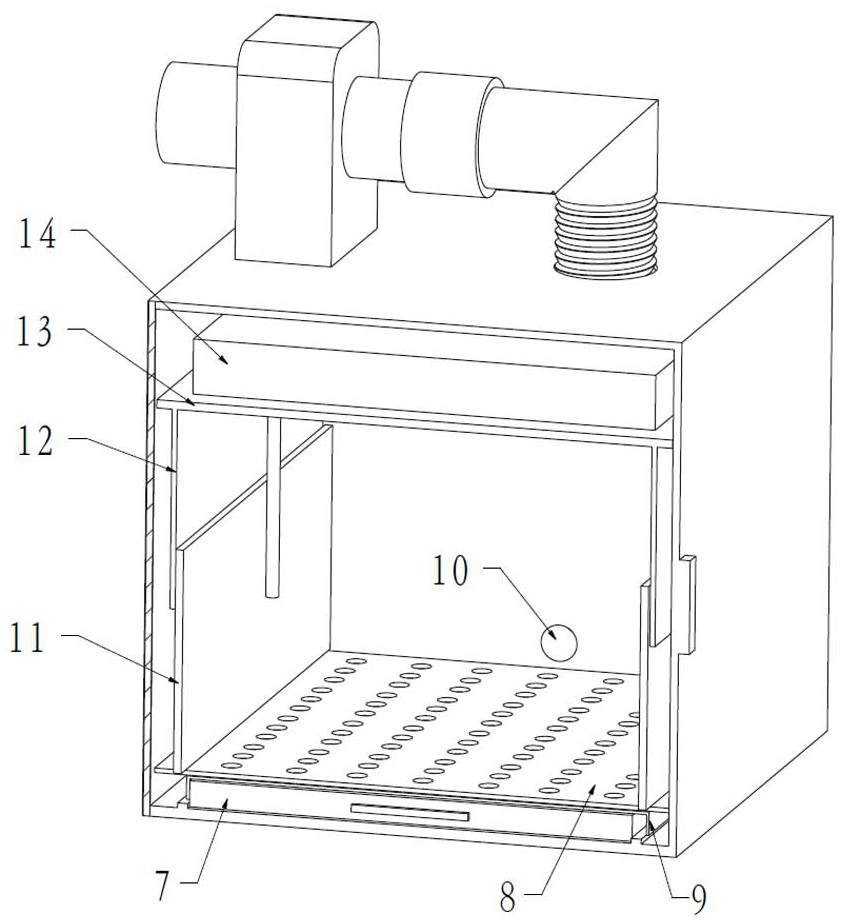

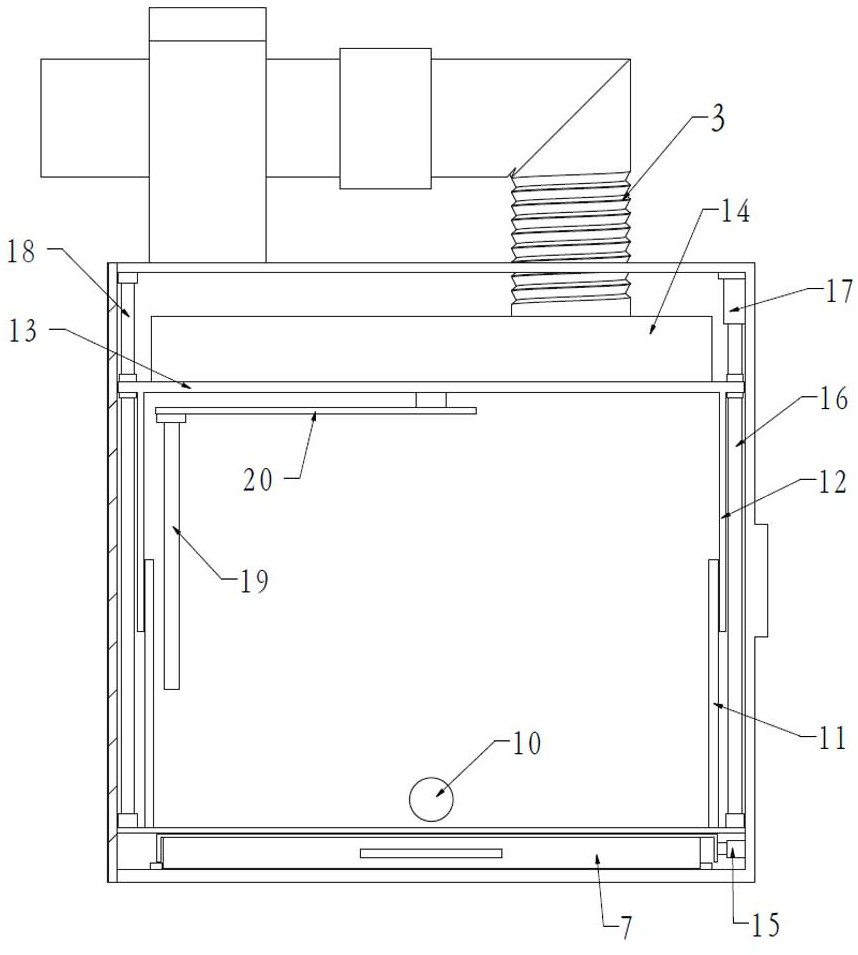

[0032] The high-efficiency moisture-proof and dust-removing device for electronic components includes a cabinet body 2, a sealed door 1 is provided at the front end of the cabinet body 2, a support plate 8 is provided at the inner lower part of the cabinet body 2, a desiccant box 7 is movable below the support plate 8, and the support plate 8 and the desiccant box 7 are provided with a slide plate 9, and the support plate 8 and the slide plate 9 are provided with ventilation holes; the cabinet body 2 is provided with a lift plate 13 above the support plate 8, and the lift plate 13 Slotted holes 23 are provided, and an exhaust hood 14 is arranged above the lifting plate 13. The exhaust hood 14 is connected to the exhaust machine 6 through the exhaust pipe 4, and the exhaust machine 6 is located at the top of the cabinet body 2; the rear wall of the cabinet body 2 The lower part is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com