Fuel cell automobile tail gas mixing system and control method thereof

A fuel cell and vehicle exhaust technology, applied in fuel cells, mixing methods, mixers, etc., can solve problems such as the inability to always guarantee the hydrogen content in the discharge, and the non-dilutable adjustment of the hydrogen concentration, so as to change the airflow direction, improve hydrogen safety, Effect of exhaust noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following specific examples illustrate the present invention in further detail.

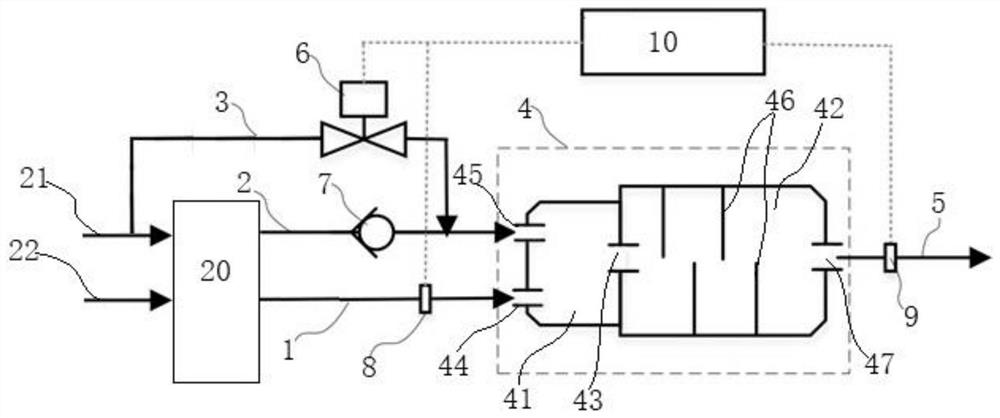

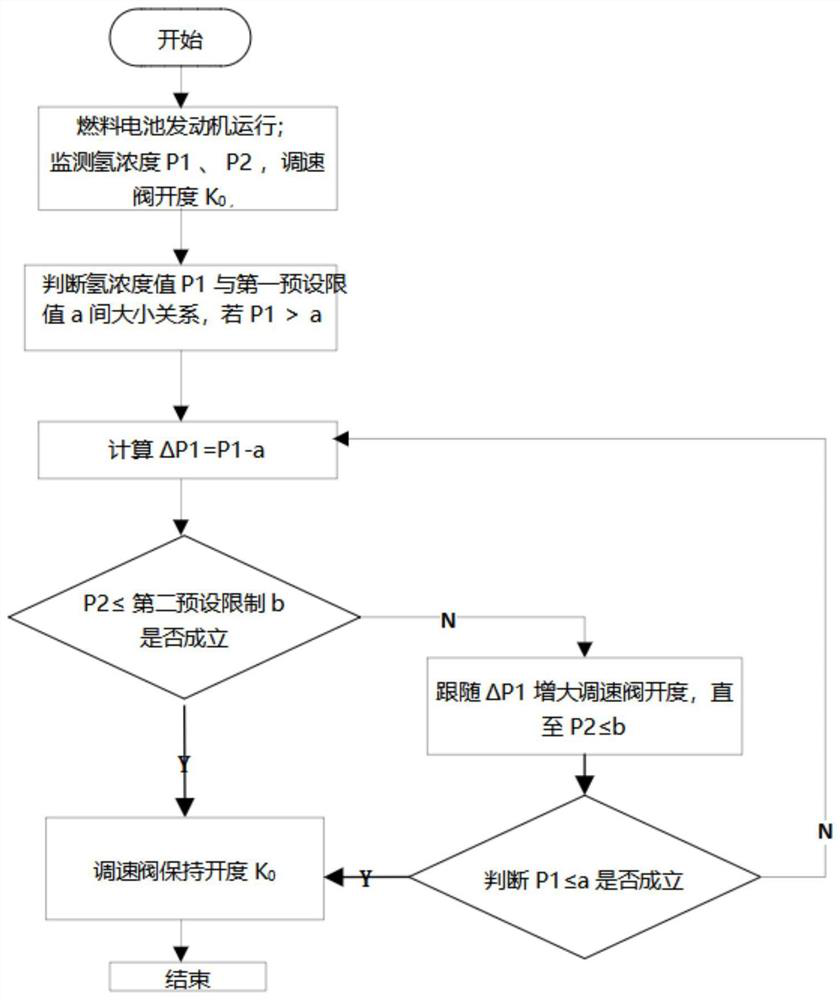

[0033] Such as figure 1 As shown, a fuel cell vehicle exhaust gas mixing system includes an anode exhaust pipeline 1, a cathode exhaust pipeline 2, a dilution gas pipeline 3, an exhaust mixer 4, a mixing discharge pipe 5, and a controller 10. The gas flows to the provided mixing chamber 41 and the silencer chamber 42, and the anode tail gas pipeline 1 and the cathode tail gas pipeline 2 are connected to the mixing chamber 41 for introducing the anode tail gas and the cathode tail gas of the fuel cell 20 into the mixing chamber 41 for mixing and diluting The gas pipe 3 is connected with the cathode tail gas pipe 2 for leading the fresh air flowing to the cathode inlet of the fuel cell 20 to the cathode tail gas pipe 2, and the mixing discharge pipe 5 is connected with the muffler chamber 42 for discharging the muffled mixed tail gas into the atmosphere . The fuel cell 20 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com