Alcohol-free fountain solution

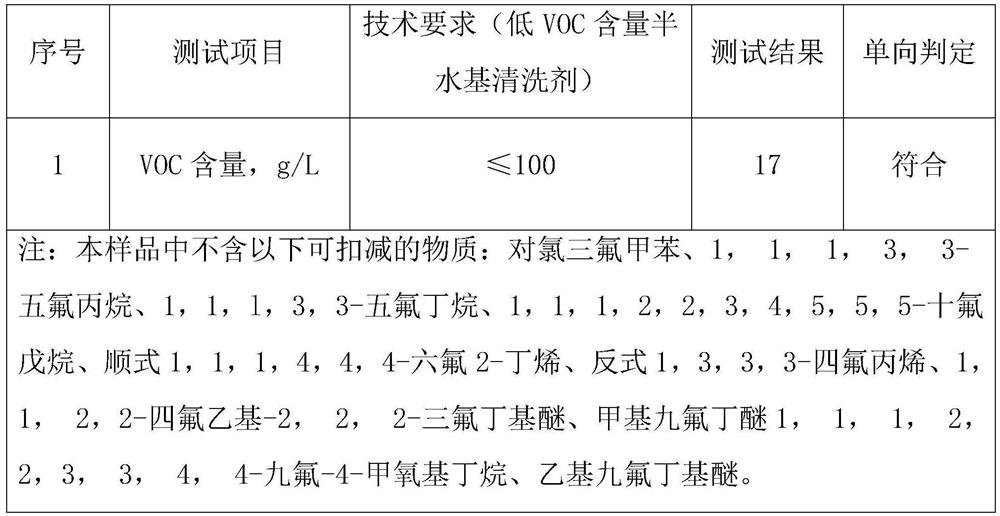

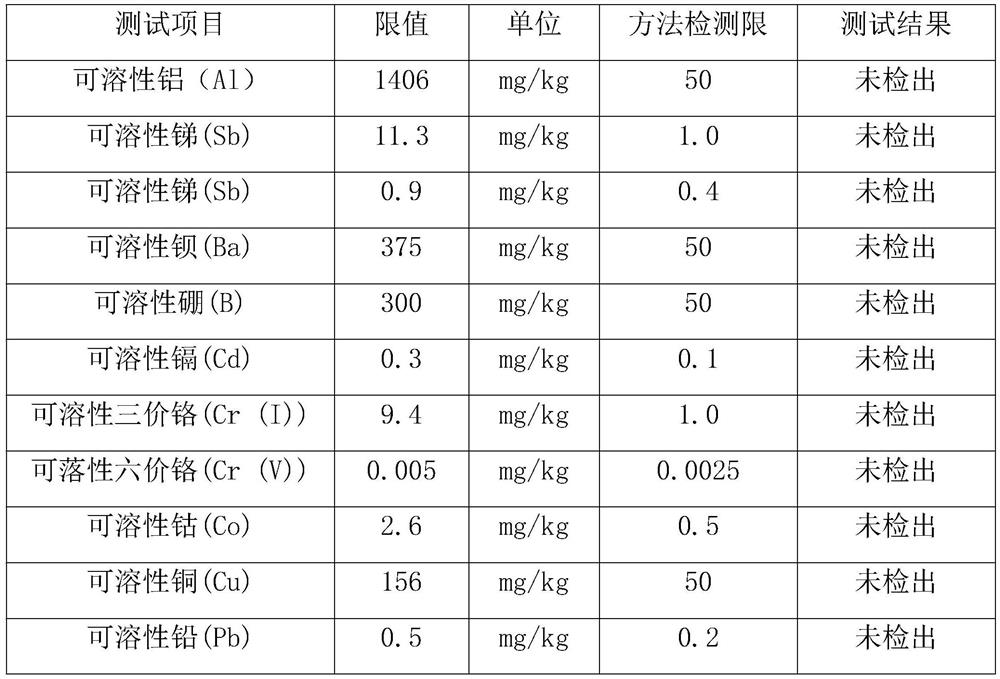

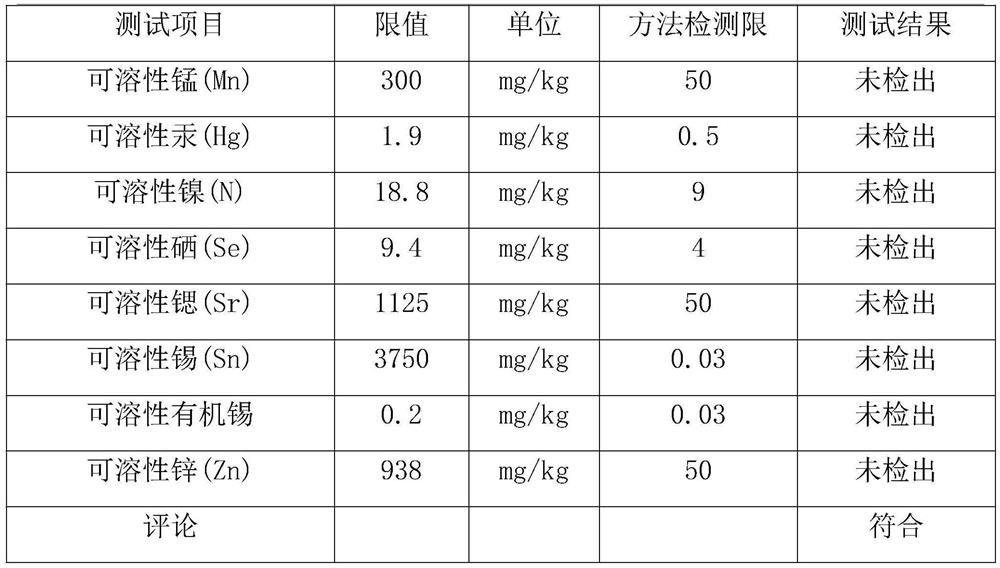

A technology of alcohol fountain solution and antifreeze, which is applied in the field of printing fountain solution, which can solve the problems of high emission of volatile organic compounds, failure to meet export standards, high material cost, etc., and achieve low VOC emission and low soluble element content Low, little environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A preparation method of alcohol-free fountain solution, comprising the following steps:

[0018] (1), each raw material is weighed by mass percentage;

[0019] (2), adding each raw material into water in turn, stirring evenly to obtain a mixture;

[0020] (3), the mixture is left to stand for several hours, and then packaged to obtain the finished product;

[0021] (4), the finished product is tested, and after passing the test, it is packaged and stored.

Embodiment 1

[0023] An alcohol-free fountain solution, which is composed of the following substances according to mass percentage: 30% water, 0.5% sodium hydroxide, 1% sodium nitrate, 1% sodium citrate, 1% sorbitol, 0.5% preservative, Ethylene glycol tert-butyl ether 40%, surfactant 3%, defoamer 0.7%, citric acid monohydrate 0.8%, glycerin 13.5%, antifreeze 8%.

Embodiment 2

[0025] An alcohol-free fountain solution, which is composed of the following substances according to mass percentage: 25% water, 1% sodium hydroxide, 2% sodium nitrate, 2% sodium citrate, 2% sorbitol, 0.3% preservative, Ethylene glycol tert-butyl ether 43%, surfactant 4%, defoamer 1.7%, citric acid monohydrate 1%, glycerin 8%, antifreeze 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com