Flame-retardant polypropylene composite material as well as preparation method and application thereof

A technology of flame-retardant polypropylene and composite materials, which is applied in the field of flame-retardant polypropylene composite materials and its preparation, can solve the problems of large influence on the mechanical properties of polypropylene fibers, large additions, and restrictions, and achieve improved mixing and dispersion effects and improved Effect of wetting and coating, low melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

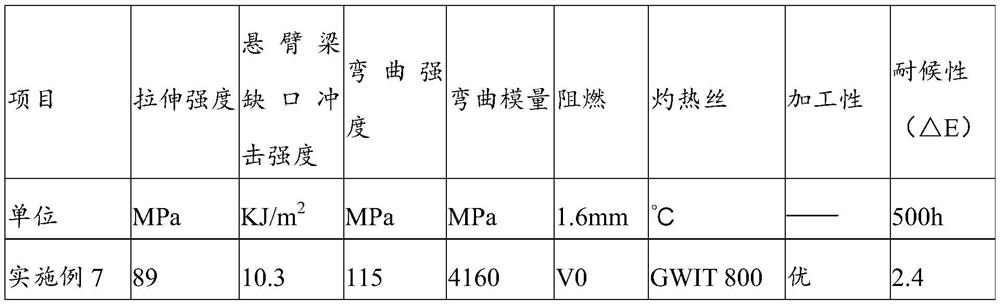

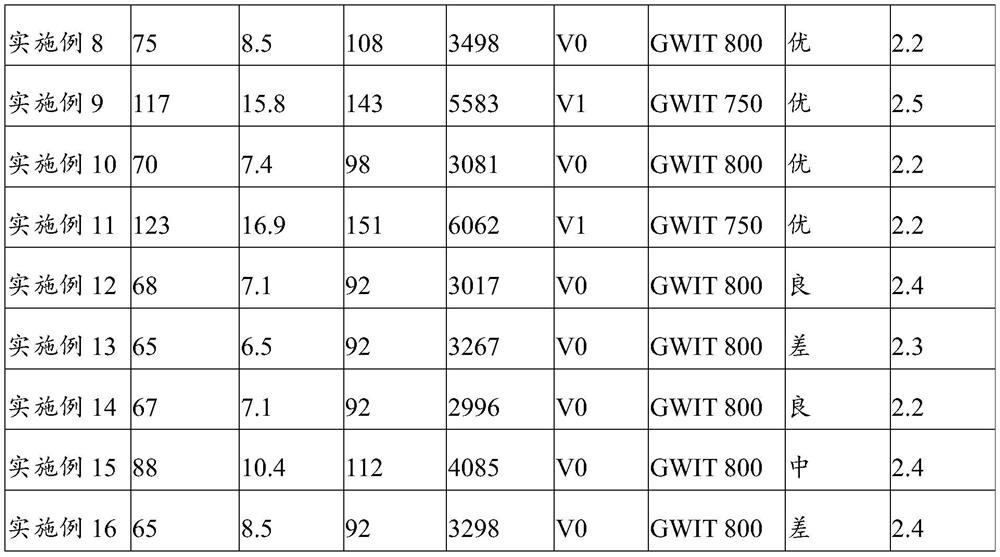

Examples

Embodiment 1

[0094] This embodiment is modified polypropylene and its preparation method.

[0095] Modified polypropylene is composed of the following raw materials in mass percentage: low isotactic polypropylene 55% (brand: S600, Japan Idemitsu Kosan Co., Ltd., melt mass flow rate is 450g / 10min, molecular weight 70000, melting point 85 ℃) , long glass fiber 40% (brand: ER4305PM-2400, Chongqing International Composite Materials Co., Ltd., linear density 2400tex, fiber diameter 11μm), compatibilizer 4.6% (brand: CA100, Arkema Chemical Co., Ltd., melting Body mass flow rate is 96g / 10min, grafting rate is 0.8%), antioxidant 1010: 0.1% (model: SONOX 1010, Sanfeng Chemical Co., Ltd., Linyi City, Shandong Province), antioxidant 168: 0.1% (model : SONOX 168, Sanfeng Chemical Co., Ltd., Linyi City, Shandong Province), lubricant 0.2% (model: EBS, Beijing Xingbeida Chemical Materials Co., Ltd.).

[0096] The preparation method of the modified polypropylene of the present embodiment comprises the fo...

Embodiment 2

[0101] This embodiment is modified polypropylene and its preparation method.

[0102]The modified polypropylene is composed of the following raw materials in mass percentage: low isotactic polypropylene 50% (brand: S600, Japan Idemitsu Kosan Co., Ltd., the melt mass flow rate is 450g / 10min, the molecular weight is 70000, and the melting point is 85°C) , long glass fiber 45% (brand: ER4305PM-2400, Chongqing International Composites Co., Ltd., linear density is 2400tex, fiber diameter is 11μm), compatibilizer 4.4% (brand: CA100, Arkema Chemical Co., Ltd., melting Body mass flow rate is 96g / 10min, grafting rate is 0.8%), antioxidant 1010: 0.15% (model: SONOX 1010, Sanfeng Chemical Co., Ltd., Linyi City, Shandong Province), antioxidant 168: 0.15% (model : SONOX 168, Sanfeng Chemical Co., Ltd., Linyi City, Shandong Province), lubricant 0.3% (model: EBS, Beijing Xingbeida Chemical Materials Co., Ltd.).

[0103] The preparation method of the modified polypropylene of the present emb...

Embodiment 3

[0108] This embodiment is modified polypropylene and its preparation method.

[0109] The modified polypropylene is composed of the following raw materials in mass percentage: low isotactic polypropylene 45% (brand: S600, Japan Idemitsu Kosan Co., Ltd., the melt mass flow rate is 450g / 10min, the molecular weight is 70000, and the melting point is 85°C) , long glass fiber 50% (brand: SE4805-2400, Owens Corning, USA, linear density is 2400tex, fiber diameter is 11μm), compatibilizer 4.1% (brand: KT-1, Shenyang Ketong Plastic Co., Ltd., Melt mass flow rate is 117g / 10min, grafting rate is 0.7%), antioxidant 1010:0.2% (model: SONOX 1010, Sanfeng Chemical Co., Ltd., Linyi City, Shandong Province), antioxidant 168: 0.2% ( Model: SONOX 168, Sanfeng Chemical Co., Ltd., Linyi City, Shandong Province), lubricant 0.5% (Model: EBS, Beijing Xingbeida Chemical Materials Co., Ltd.).

[0110] The preparation method of the modified polypropylene of the present embodiment comprises the followin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com