Ablation type sealing silicone rubber adhesive and preparation method thereof

A silicone rubber and adhesive technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of poor adhesion performance, ablation resistance and scratch performance, and achieve good application prospects. The effect of excellent environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

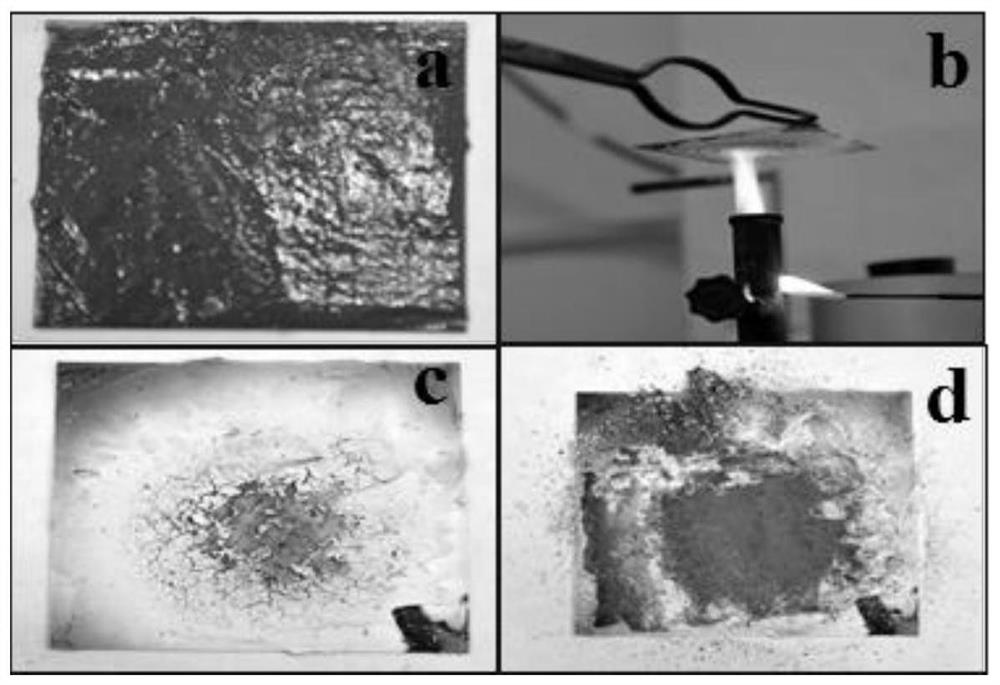

Image

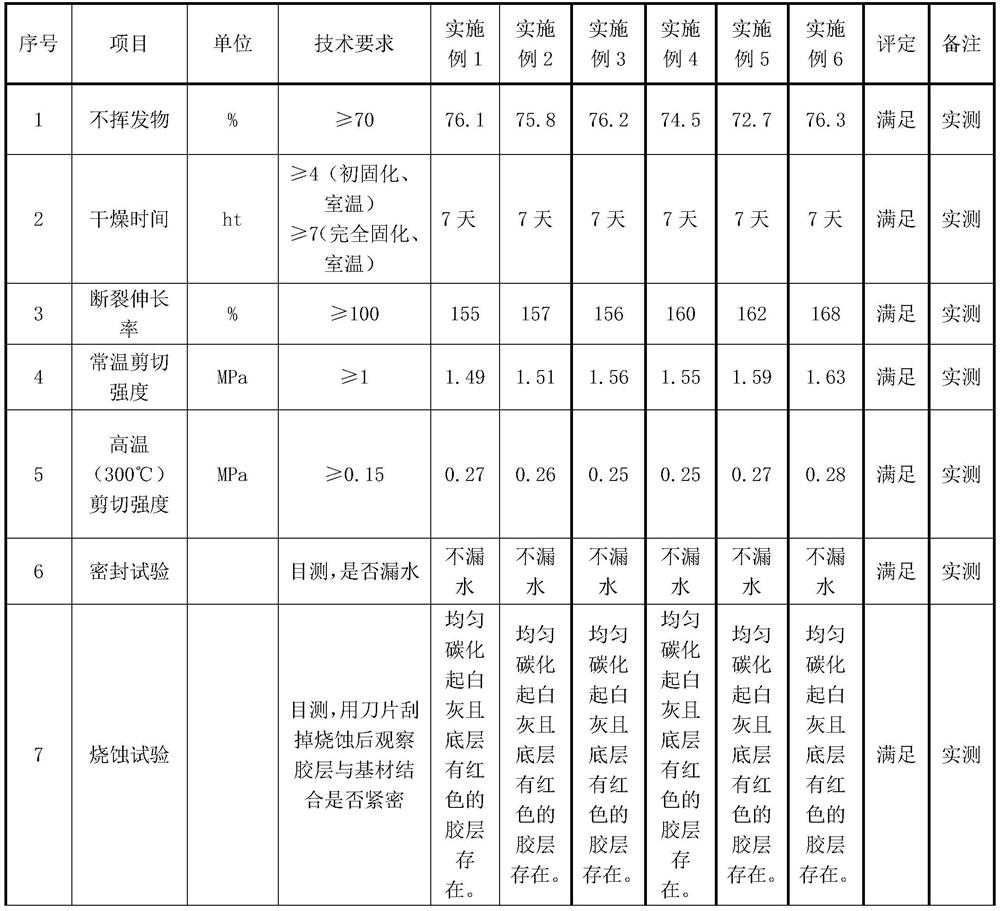

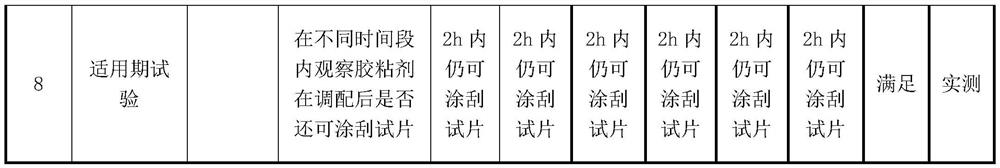

Examples

Embodiment 1

[0024] 1. An ablative sealing silicone rubber adhesive, the composition of which is calculated in parts by weight:

[0025] Component A: 100 parts of methyl bisphenyl room temperature vulcanized silicone rubber, 1 part of fumed silica, 3 parts of talc powder, 4 parts of silane coupling agent, 3 parts of toluene;

[0026] Component B: 5 parts of tetraethyl orthosilicate;

[0027] Component C: 0.7 parts of dibutyltin dilaurate.

[0028] 2. The preparation method of the above-mentioned ablative sealing silicone rubber adhesive is to first weigh methyl biphenyl room temperature vulcanized silicone rubber, fumed silica, talcum powder, silane coupling agent and toluene according to the formula to prepare component A, When in use, add component B and component C for mixing, then place the obtained mixture on the scraper with a scraper, and scrape the mixture back and forth with the scraper to further ensure the uniformity of the rubber material to obtain qualified ablation Type-sea...

Embodiment 2

[0030] A kind of ablation type sealing silicone rubber adhesive, its composition is calculated by weight:

[0031] Component A: 100 parts of methyl bisphenyl room temperature vulcanized silicone rubber, 1 part of fumed silica, 2 parts of talcum powder, 4 parts of silane coupling agent, 3 parts of toluene;

[0032] Component B: 5 parts of tetraethyl orthosilicate;

[0033] Component C: 0.3 parts of dibutyltin dilaurate.

[0034] The adhesive was prepared according to the preparation method of Example 1.

Embodiment 3

[0036] A kind of ablation type sealing silicone rubber adhesive, its composition is calculated by weight:

[0037] Component A: 100 parts of methyl bisphenyl room temperature vulcanized silicone rubber, 5 parts of fumed silica, 4 parts of talc powder, 3 parts of silane coupling agent, 6 parts of toluene;

[0038] Component B: 8 parts of tetraethyl orthosilicate;

[0039] Component C: 0.8 parts of dibutyltin dilaurate.

[0040] The adhesive was prepared according to the preparation method of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com