Heat dissipation system for slurry pump

A heat dissipation system and slurry pump technology, applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve the problems of sound insulation protective covers, unfavorable cooling fans, poor air flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

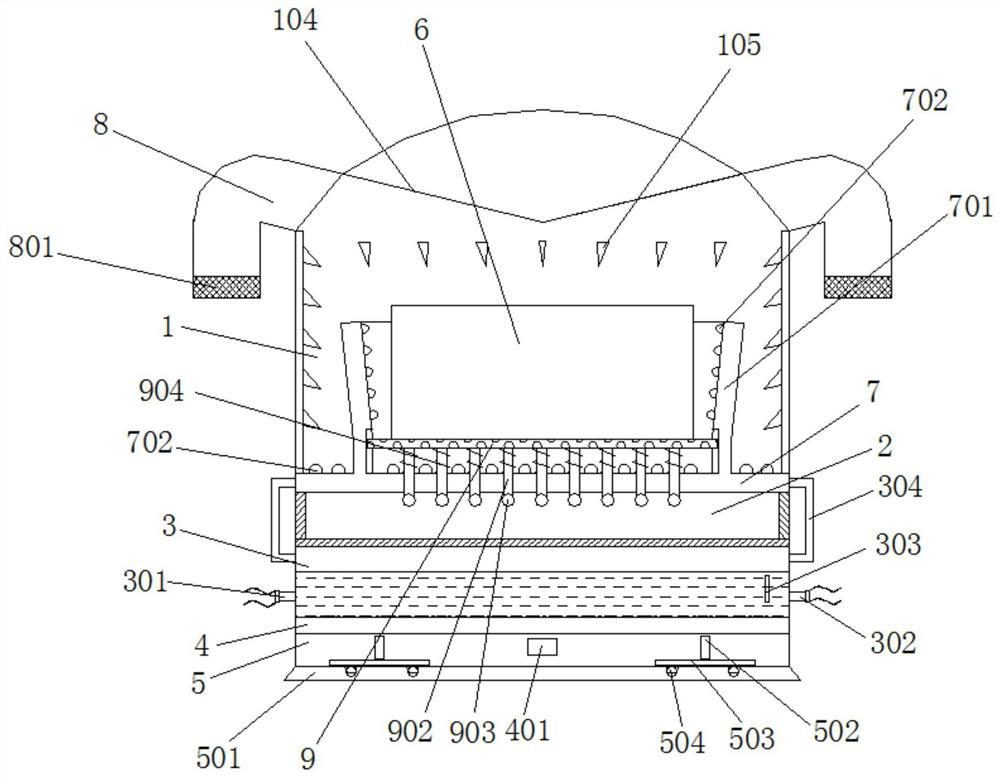

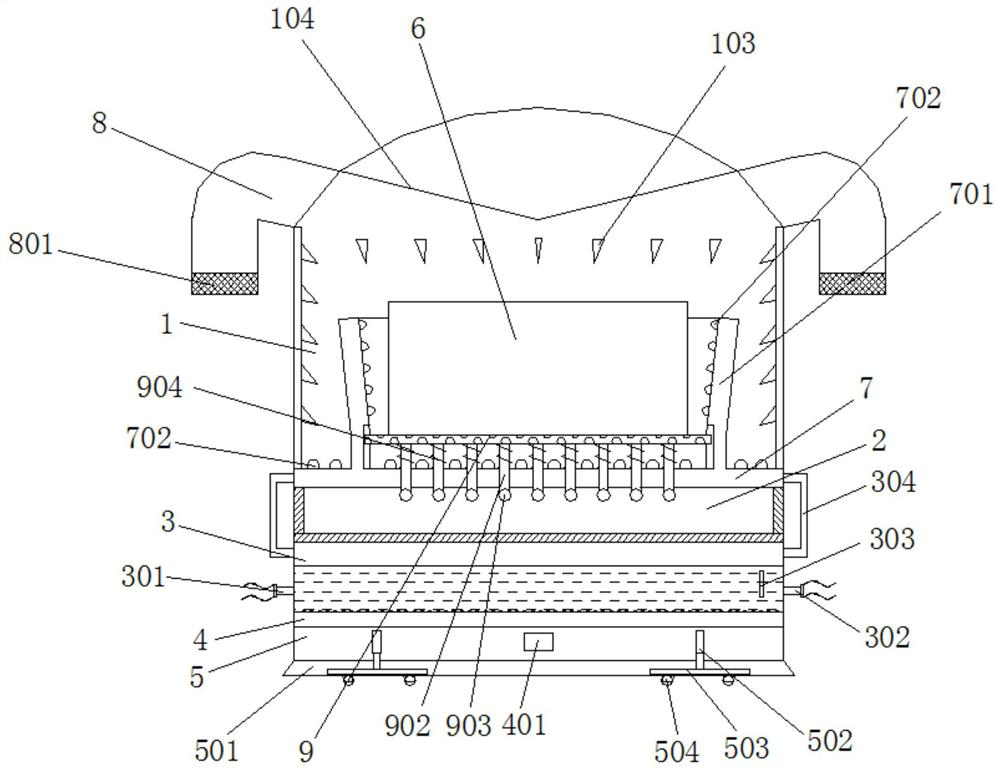

[0027] Embodiment 1: as Figure 1-6 As shown, a heat dissipation system of a slurry pump includes a base 5, an aeration pan 4 is fixedly installed on the top of the base 5, and a water cavity 3 is fixedly installed on the top of the aeration pan 4. The telescoping chamber 2 is fixedly installed on the top of the chamber 3 , the air chamber 7 is fixedly installed on the top of the telescopic chamber 2 , and the muffler cover 1 is fixedly installed on the top of the air chamber 7 .

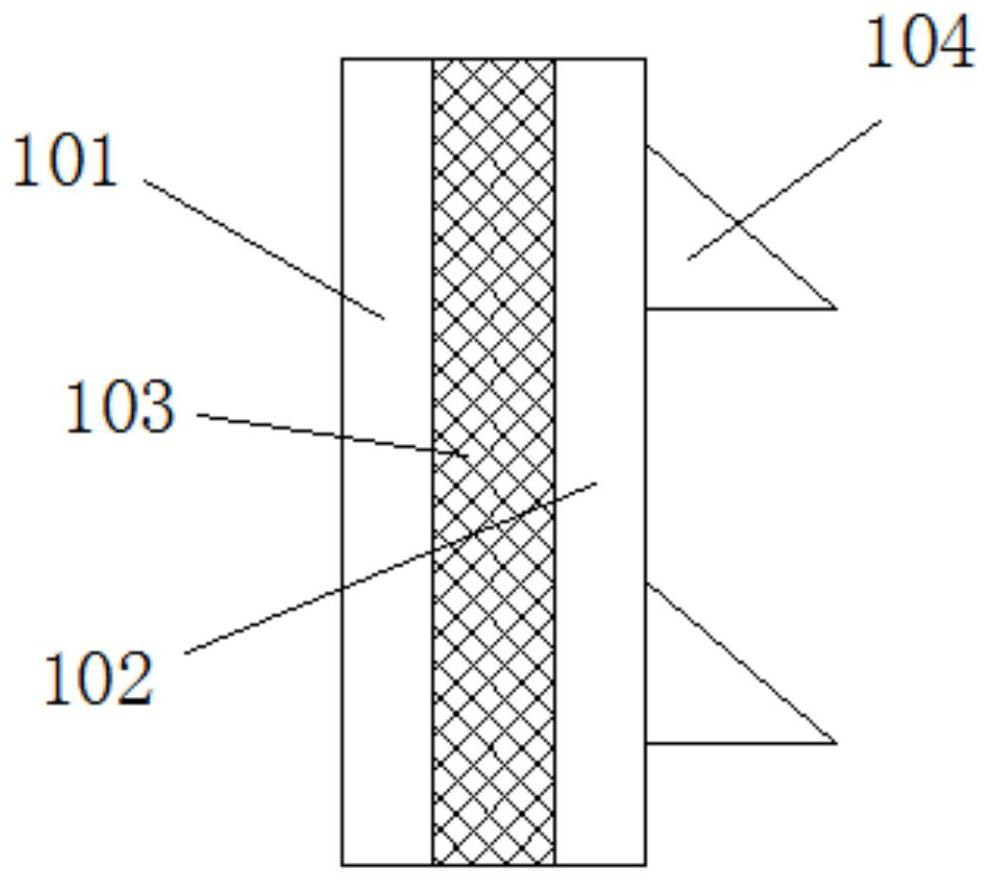

[0028] The sound-absorbing cover 1 is arranged in double layers, which are an outer cover 101 and an inner cover 102 respectively, and a sound-insulating cotton 103 is arranged between the outer cover 101 and the inner cover 102, and a plurality of sound-absorbing wedges 105 are fixedly connected to the inner wall of the sound-absorbing cover 1 A guide plate 104 is provided on the fixed side of the inner cavity of the sound-absorbing cover 1 .

[0029] The top side of the air cavity 7 is fixedly co...

Embodiment 2

[0039] Embodiment 2: as Figure 1-6 As shown, a heat dissipation system of a slurry pump includes a base 5, an aeration pan 4 is fixedly installed on the top of the base 5, and a water cavity 3 is fixedly installed on the top of the aeration pan 4. The telescoping chamber 2 is fixedly installed on the top of the chamber 3 , the air chamber 7 is fixedly installed on the top of the telescopic chamber 2 , and the muffler cover 1 is fixedly installed on the top of the air chamber 7 .

[0040] The sound-absorbing cover 1 is arranged in double layers, which are an outer cover 101 and an inner cover 102 respectively, and a sound-insulating cotton 103 is arranged between the outer cover 101 and the inner cover 102, and a plurality of sound-absorbing wedges 105 are fixedly connected to the inner wall of the sound-absorbing cover 1 A guide plate 104 is provided on the fixed side of the inner cavity of the sound-absorbing cover 1 .

[0041] The top side of the air cavity 7 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com