Lifting hydraulic system of tubing string and using method of lifting hydraulic system

A hydraulic system and tubing string technology, applied in drilling pipe, casing, earthwork drilling and production, etc., can solve the problems of complicated control system, high installed power of lifting equipment, waste, etc., and achieve simple mechanical structure, energy saving, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

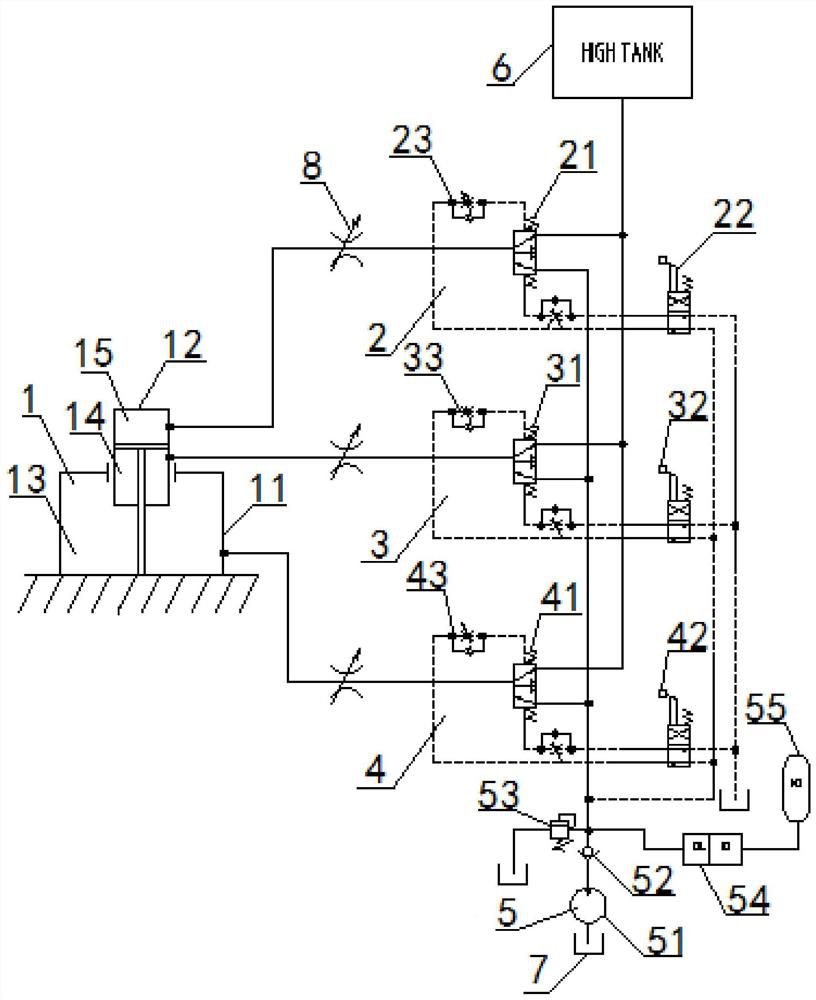

[0060] A lifting hydraulic system for an oil pipe string, the lifting hydraulic system includes: a combined hydraulic cylinder 1, a first hydraulic valve group 2, a second hydraulic valve group 3, a third hydraulic valve group 4, a hydraulic supply system 5, and a pressure oil tank 6 and the normal pressure oil tank 7; the combined hydraulic cylinder 1 includes a coaxial plunger cylinder 11 and a piston cylinder 12, the piston cylinder 12 is arranged inside the plunger cylinder 11, and the side wall of the piston cylinder 12 is connected to the column The piston cylinder port on the top of the plug cylinder 11 is slidingly fitted, and the piston cylinder 12 is in sealing fit with the plunger cylinder 11. The plunger cylinder 11 is provided with a plunger oil chamber 13, and the piston cylinder 12 is provided with a first oil chamber. chamber 14 and the second oil chamber 15, the oil outlet end of the first hydraulic valve group 2 communicates with the second oil chamber 15 prov...

Embodiment 2

[0070] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

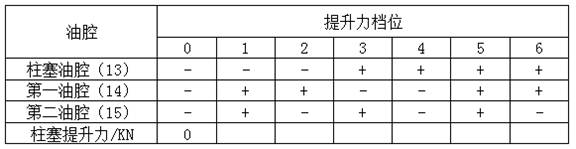

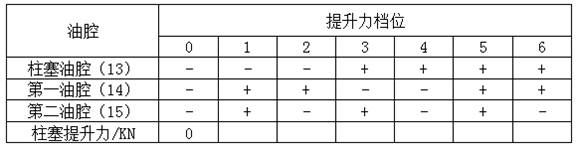

[0071] The second step: in the judging step, the lifting force gear of the lifting hydraulic system is shown in Table 1:

[0072] Table 1:

[0073]

Embodiment 3

[0075] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0076] In the third lowering step, when the operator judges that the gravitational force on the tubing string is greater than the sum of the resistance provided by the plunger oil chamber 13 and the second oil chamber 15 and the lifting force provided by the first oil chamber 14 after work, the operator shall operate Personnel manually switch the gear position of the second manual reversing valve 32, so that the hydraulic oil enters the liquid control end of the second hydraulic control reversing valve 31 after passing through the oil inlet port and the working port of the second manual reversing valve 32, and the hydraulic oil enters The liquid control end of the second hydraulic control reversing valve 31 drives the second hydraulic control reversing valve 31 to reversing. The oil passage at the oil outlet is connected, and the hydraulic oil enters the first oil chamber 14. At this time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com