Laser trace vacuum pipeline gas detection device and method based on photoacoustic spectroscopy

A vacuum pipeline and photoacoustic spectroscopy technology, which is applied in the direction of measuring devices, gas/liquid distribution and storage, pipeline systems, etc., to achieve the effects of improving detection efficiency, fast response time, and high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific content of the present invention will be further explained in detail below in conjunction with the examples.

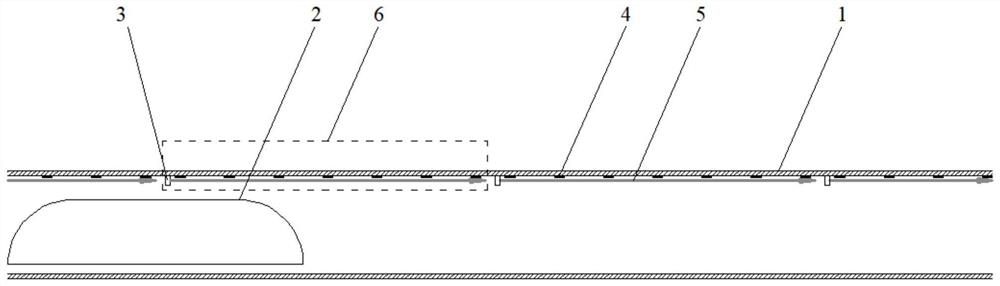

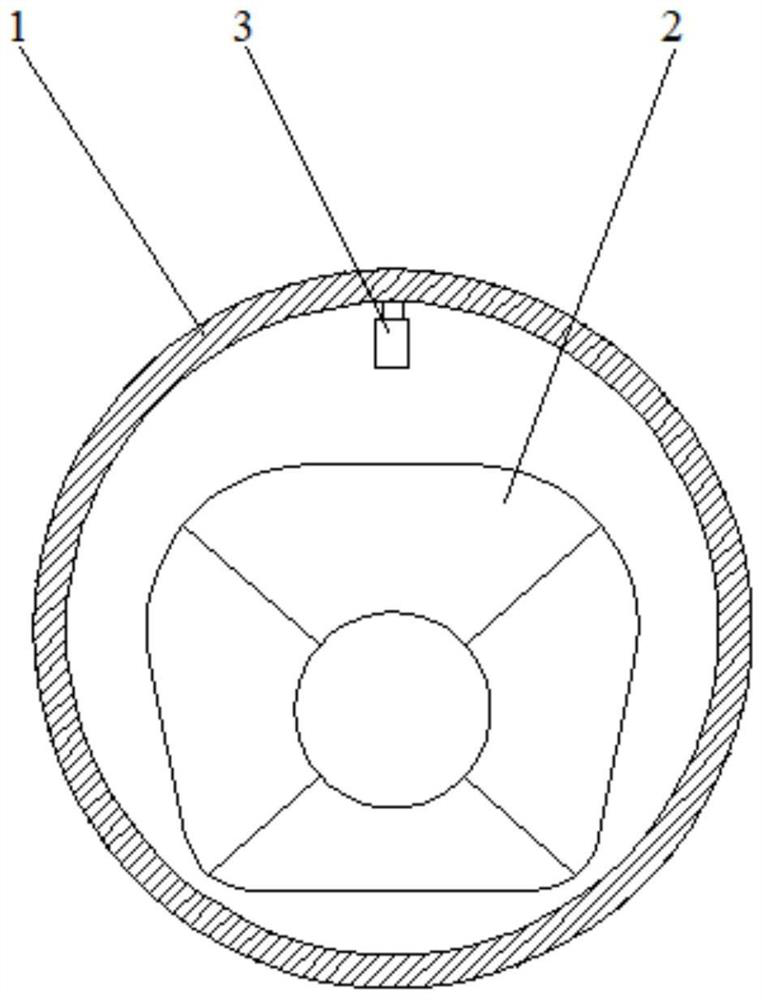

[0057] like Figures 1 to 12 As shown, the laser trace vacuum pipeline gas detection device based on photoacoustic spectroscopy includes a plurality of detection units 6 arranged on the inner wall of the vacuum pipeline 1 to detect the concentration change of the gas 7 inside the pipeline in the corresponding area. The detection unit 6 includes a correspondingly arranged laser 3 and an acoustic wave detector 4;

[0058] Each acoustic wave detector 4 is provided with a unique coding label corresponding to its position in the vacuum pipeline 1, corresponding to its position;

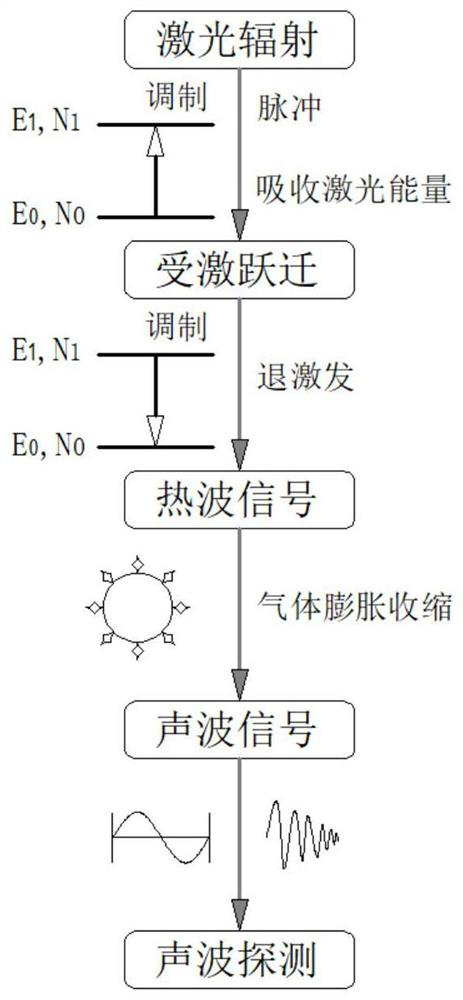

[0059] The laser 3 includes a laser emitter 32 and an optical chopper 31; the function of the laser emitter 32 is to emit laser light, and the function of the optical chopper 31 is to modulate the intensity of the laser beam to generate sound wave energy of the same frequency....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com