Pyrolysis product monitoring device and method based on P-Q regression model of phenolic resin low-temperature pyrolysis gas

A low-temperature pyrolysis and regression model technology, applied in measurement devices, complex mathematical operations, instruments, etc., can solve problems such as insufficient fire accident monitoring capabilities, and achieve more convenient measurement data and avoid accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

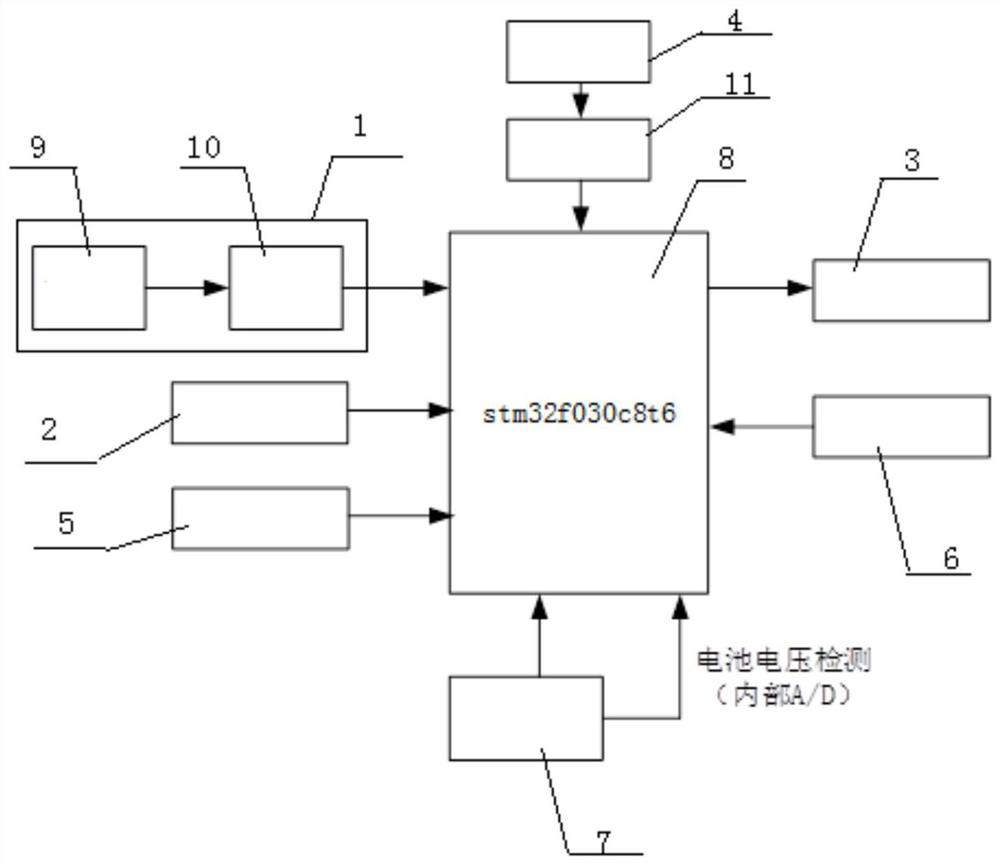

[0067] A pyrolysis product monitoring device based on the P-Q regression model of the low-temperature pyrolysis gas of phenolic resin in this embodiment, such as figure 1 As shown, its composition includes:

[0068] The gas sampling pressure difference detection module 1 is used to sample the gas generated by the thermal analysis of the thermal insulation material, and realize the real-time detection of the pressure difference between the thermal analysis gas of the thermal insulation material and the standard atmospheric pressure, and the measurement range is 0kPa to 10kPa;

[0069] Clock module 2, used to display the current clock when the instrument is running, if there is a deviation from the standard clock, you can enter the "time setting" menu to modify the clock, and press the enter button to modify;

[0070] The display module 3 is used for human-computer interaction. The human-computer interaction interface is a dot-matrix liquid crystal display, and the SPI liquid cr...

specific Embodiment approach 2

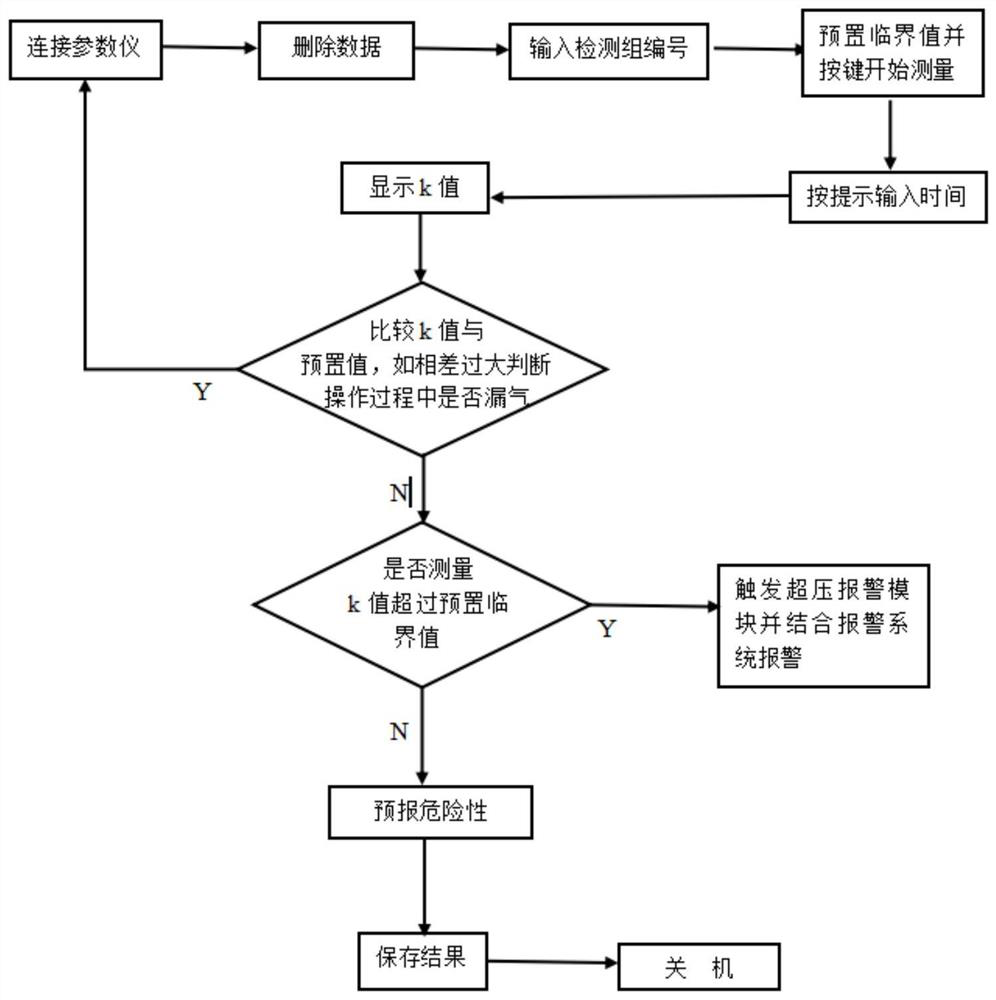

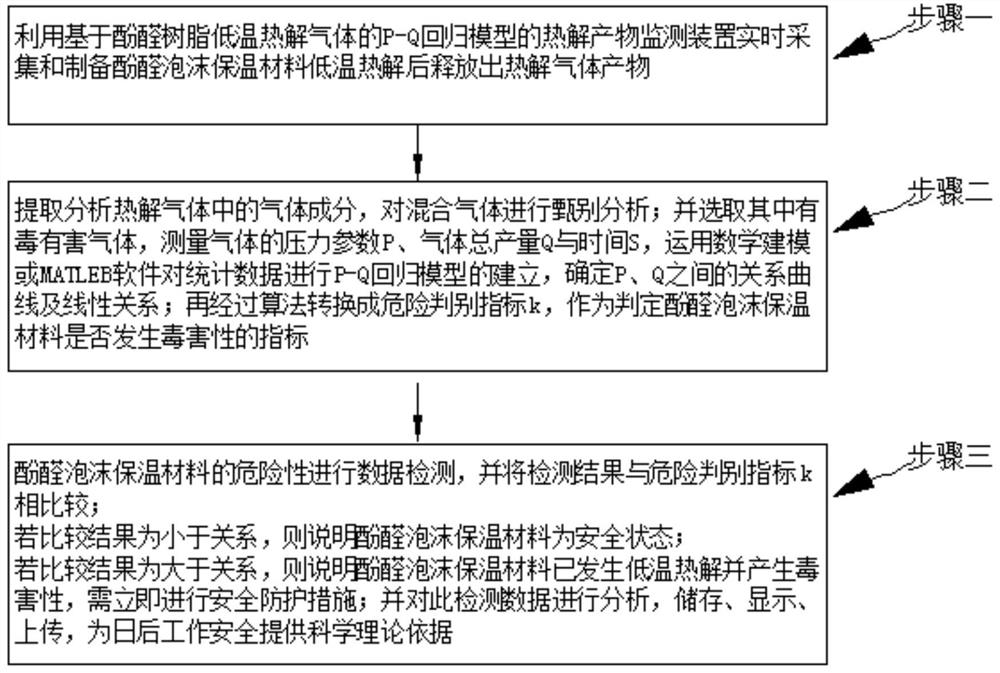

[0092] The difference from the specific embodiment one is that a pyrolysis product monitoring method based on the P-Q regression model of the low-temperature pyrolysis gas of phenolic resin in this embodiment, such as image 3 As shown, the method is realized through the following steps:

[0093] Step 1, using the pyrolysis product monitoring device based on the P-Q regression model of the low-temperature pyrolysis gas of phenolic resin to collect and prepare in real time the pyrolysis gas product released after low-temperature pyrolysis of the phenolic foam insulation material;

[0094]Step 2: extract and analyze the gas components in the pyrolysis gas, and screen and analyze the mixed gas; select toxic and harmful gases, measure the pressure parameter P of the gas, the total gas output Q and the time S, and use mathematical modeling or MATLEB software to analyze Statistical data is used to establish the P-Q regression model to determine the relationship curve and linear rela...

specific Embodiment approach 3

[0099] Different from the first or second specific embodiment, a pyrolysis product monitoring method based on the P-Q regression model of the low-temperature pyrolysis gas of phenolic resin in this embodiment,

[0100] The extraction and analysis of the gas components in the pyrolysis gas described in step two, screening and analysis of the mixed gas; and selecting toxic and harmful gases, measuring the pressure parameter P of the gas, the total gas output (Q) and time (S), using mathematics Modeling or MATLEB software is used to establish a P-Q regression model for statistical data, and determine the relationship curve and linear relationship between P and Q; and then convert it into a risk discrimination index k through an algorithm, as an index to determine whether the phenolic foam insulation material is toxic process, specifically:

[0101] When the phenolic foam insulation material is pyrolyzed at low temperature, the mixed toxic gas is decomposed, and the relationship b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com