Fused biconical taper-based multi-core optical fiber coupler with high fiber core number and preparation method of fused biconical taper-based multi-core optical fiber coupler

A multi-core optical fiber and fused tapered technology, which is applied in the coupling of optical waveguides and other directions, can solve the problems of unmatched arrangement of fiber cores and increased insertion loss of couplers, etc., and achieves easy preparation, high precision, and good scalability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

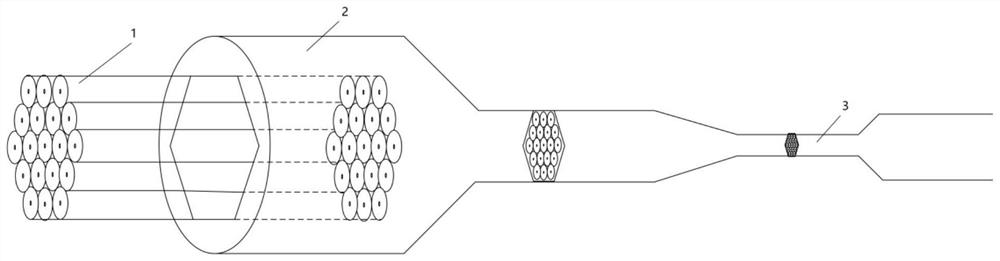

[0029] The preparation method of the multi-core optical fiber coupler provided by the invention comprises the following steps:

[0030] (1) After stripping off part of the coating layer on the surface of N single-mode optical fibers, N first intermediate pieces are obtained; the first intermediate piece is divided into two parts, one part is an optical fiber comprising only a core layer and a cladding layer, and the other part It is a complete optical fiber including core, cladding and coating. Preferably, the coating layer of N single-mode optical fibers is stripped, and then the first intermediate piece is obtained after dedusting with a dust-free paper dipped in alcohol; the first intermediate piece is divided into two parts, and the front part is composed of a core layer and a cladding Layered optical fiber, the length is 4 to 6 cm, the rear end part is a complete optical fiber including the core layer, cladding and coating layer, the length is 1.5 to 3 meters, and N is an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com