Hollow wire and processing technology thereof

A technology of hollow wire and processing technology, which is applied in the manufacture of cables/conductors, the manufacture of extensible conductors/cables, rods/rods/wires/strip conductors, etc., which can solve the problems of high price, difficult production and processing, and eccentricity of inner holes. Asymmetry and other problems, to achieve the effect of high processing precision, good surface smoothness, and small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

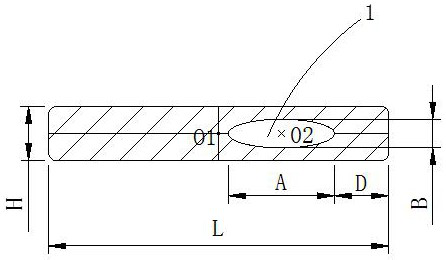

[0028] The invention firstly discloses a hollow wire, the cross section of which is rectangular, the wire is silver-copper hollow wire, the thickness of the hole walls on both sides is quite different, and it is a profile with unequal wall thickness, and its material includes 0.08-0.12% silver , the balance is copper, and a small amount of impurities, the impurity is P, and the content is controlled between 0.001-0.007%. There is a hole 1 in the wire, combined with the attached figure 1 It can be seen that the length of the rectangular cross section is L, the width is H, the hole is a circular hole or an elliptical hole, the length direction dimension of the hole is expressed as A, the width direction dimension is expressed as B, and the center of hole 1 is O 2 with the center O of the rectangular cross-section 1 do not coincide, O 1 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com