Synchronous rectification device for water-cooled laminated busbars suitable for high current transmission

A technology of stacked busbars and synchronous rectification, applied in output power conversion devices, conversion of AC power input to DC power output, electrical components, etc. Current carrying capacity, conducive to self-cooling and heat dissipation, and the effect of increasing conductive cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

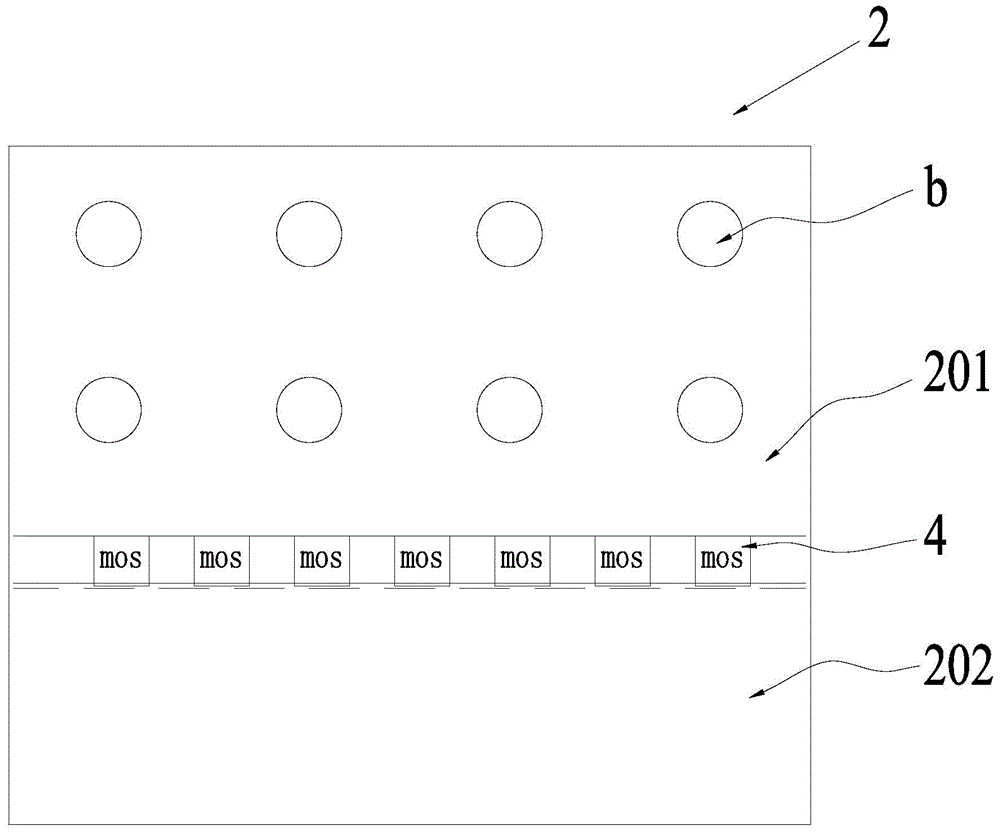

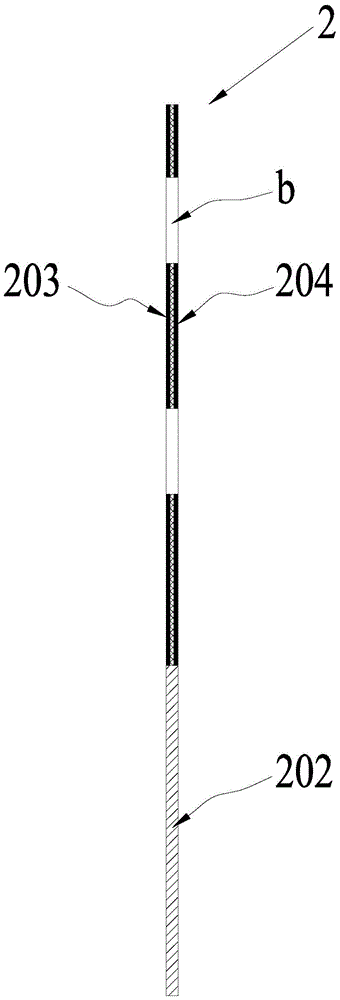

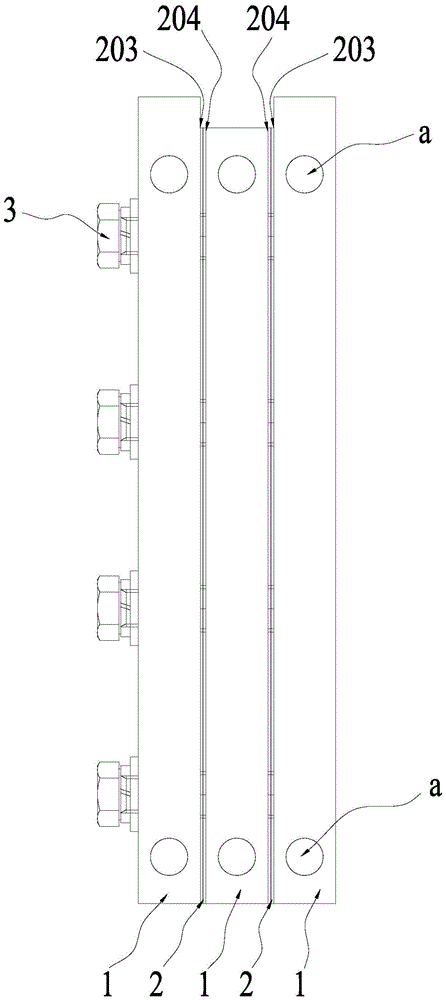

[0030] Such as Figure 1 to Figure 3 As shown, the water-cooled laminated busbar suitable for large current transmission according to the preferred embodiment of the present invention includes three conductive substrates 1 and two circuit boards 2 .

[0031] The circuit board 2 is a PCB board divided into a copper clad area 201 and a welding area 202. The front and back sides of the PCB are respectively provided with a front copper clad layer 203 and a reverse copper clad layer 204. The front copper clad layer 203 and the reverse copper clad layer 204 are insulated from each other and are all located in the copper clad area 201, and the PCB board is provided with seven groups of pad groups located in the welding area 202, the pad groups include the first polarity pad electrically connected to the front copper clad layer 203 and the The pads of the second polarity electrically connected to the copper clad layer 204 on the reverse side are evenly arranged along the boundary line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com