Planar diaphragm composite material for loudspeaker and preparation method thereof

A technology of planar diaphragm and composite materials, which is applied in the field of loudspeakers, can solve the problems that the planar diaphragm composite materials of loudspeakers are difficult to meet various requirements, and achieve the effects of enhanced rigidity, high sensitivity and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

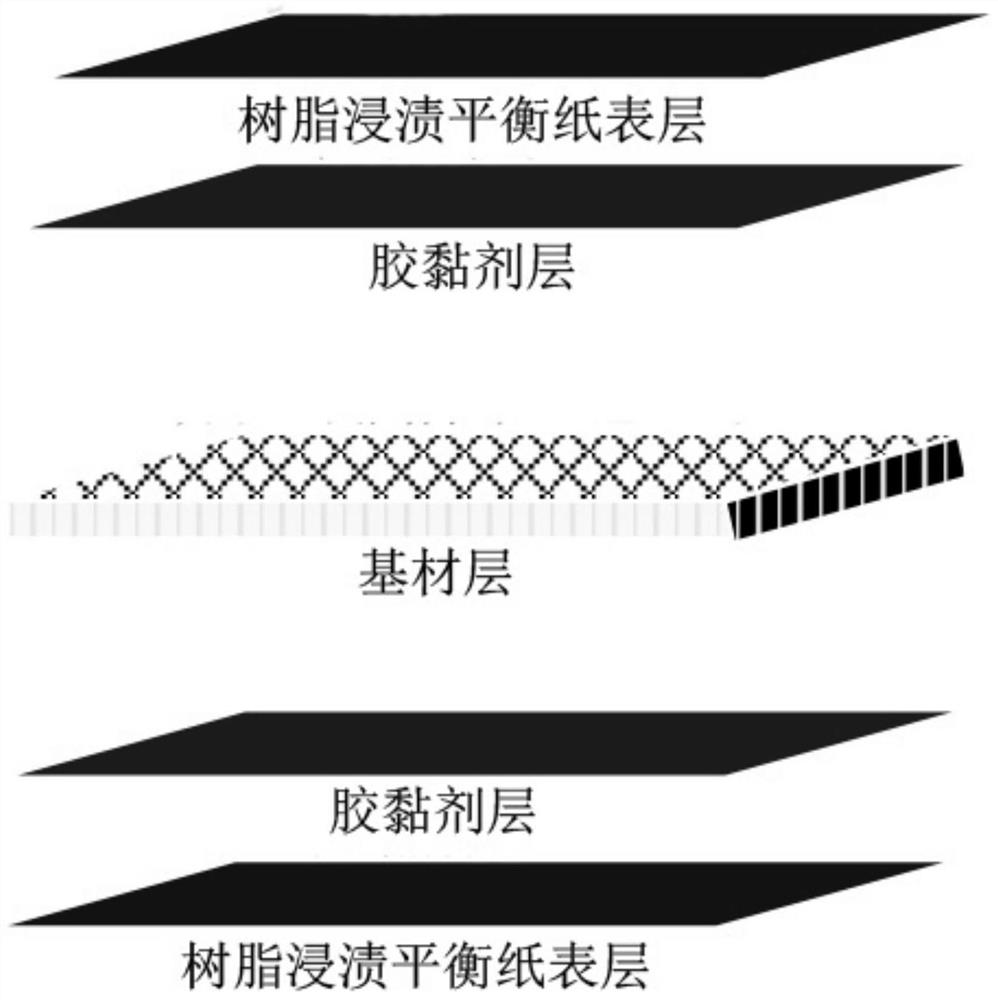

[0041] The preparation method for the planar diaphragm composite material used for the loudspeaker of the present embodiment comprises the following steps:

[0042] (1) Coating the adhesive on the surface of the resin-impregnated balance paper that needs to be glued;

[0043] (2) The surface layer of the resin-impregnated balance paper is coated with an adhesive and attached to the upper and lower surfaces of the substrate layer;

[0044] (3) bonding the resin-impregnated balance paper surface layer and the base material layer by flat hot pressing;

[0045] Wherein, the hot-pressing treatment conditions are as follows: 3 tons of pressure, hot-pressing temperature of 120° C., and holding pressure for 30 minutes.

Embodiment 2

[0047] The preparation method for the planar diaphragm composite material used for the loudspeaker of the present embodiment comprises the following steps:

[0048] (1) Coating the adhesive on the surface of the resin-impregnated balance paper that needs to be glued;

[0049] (2) The surface layer of the resin-impregnated balance paper is coated with an adhesive and attached to the upper and lower surfaces of the substrate layer;

[0050] (3) bonding the resin-impregnated balance paper surface layer and the base material layer by flat hot pressing;

[0051] Wherein, the hot-pressing treatment conditions are as follows: 5 tons of pressure, hot-pressing temperature of 150° C., and holding pressure for 25 minutes.

Embodiment 3

[0053] The preparation method for the planar diaphragm composite material used for the loudspeaker of the present embodiment comprises the following steps:

[0054] (1) Coating the adhesive on the surface of the resin-impregnated balance paper that needs to be glued;

[0055] (2) The surface layer of the resin-impregnated balance paper is coated with an adhesive and attached to the upper and lower surfaces of the substrate layer;

[0056] (3) bonding the resin-impregnated balance paper surface layer and the base material layer by flat hot pressing;

[0057] Wherein, the hot-pressing treatment conditions are as follows: 6 tons of pressure, hot-pressing temperature of 170° C., and holding pressure for 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com