Magnesium clad material, housing for electronic devices, and component for mobile objects

A magnesium cladding and cladding technology, which is applied in the field of housings for electronic equipment and parts for mobile bodies, can solve the problems of easy peeling and reduced joint strength of Mg cladding materials, achieve fire resistance and flame retardancy, and ensure light weight. Quantitative, the effect of improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

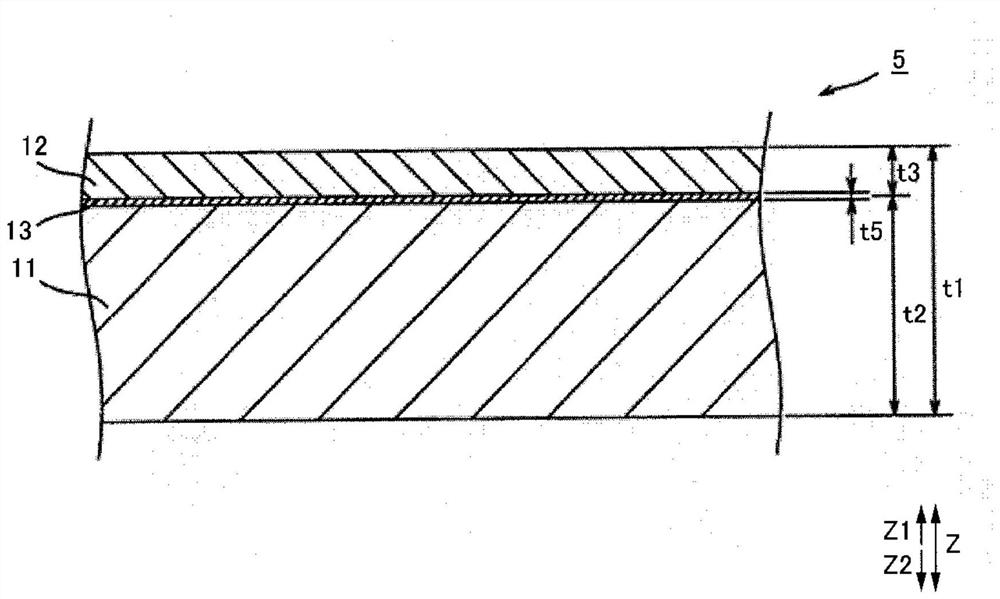

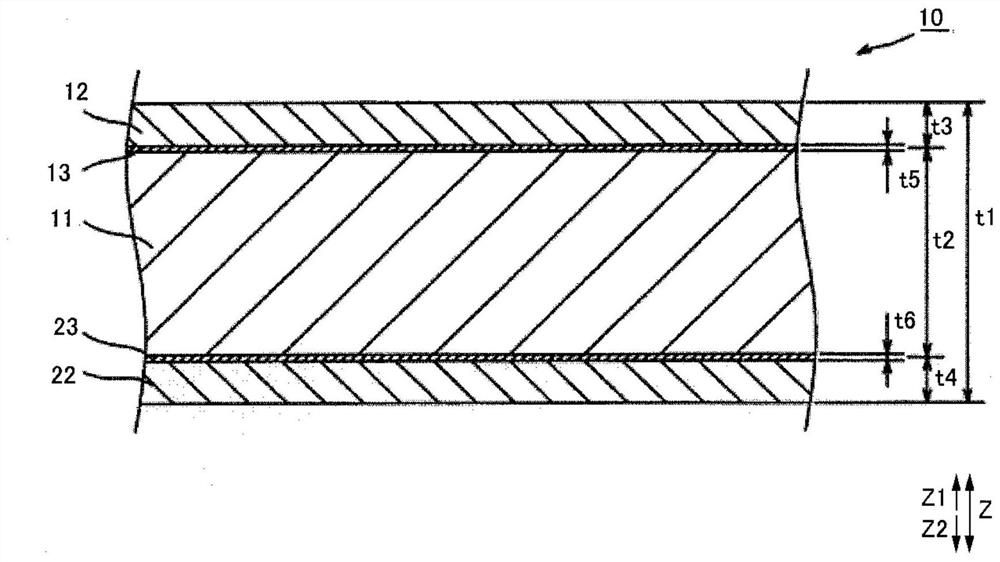

[0079] The evaluation test of the mechanical characteristics performed in order to confirm the effect of this invention, and its result are demonstrated. In consideration of the risk of corrosion of the Mg cladding material used in the evaluation test during the test, a test body was cut out from a cladding material 10 with a five-layer structure in which both sides of the Mg layer 11 were protected. In addition, as a reference, for a Mg plate with a thickness of 0.6 mm composed of Mg-Li alloy (LZ91, LAZ941), an Al plate with a thickness of 0.6 mm composed of Al alloy (A5052), and a Mg-Al - A 0.6 mm-thick Mg plate made of a Zn alloy (AZ31) was also cut out as a test piece, and evaluated in the same manner as the Mg clad material.

[0080] In the production of the clad material 10 used in the evaluation test, as its raw materials, a Mg plate with a thickness of about 3 mm, an Al plate with a thickness of about 3 mm, and a Cu plate with a thickness of about 0.03 mm were used. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com