Ultrasonic airflow cutting resistance reducing device for means of transportation

A vehicle and ultrasonic technology, which is applied in the field of flight resistance, sailing resistance component device, and driving resistance, can solve the problems affecting the driving speed of the vehicle, the energy consumption of the maximum stroke, and the difficulty of lifting, so as to achieve good shock absorption effect, The effect of improving driving range and convenient installation and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

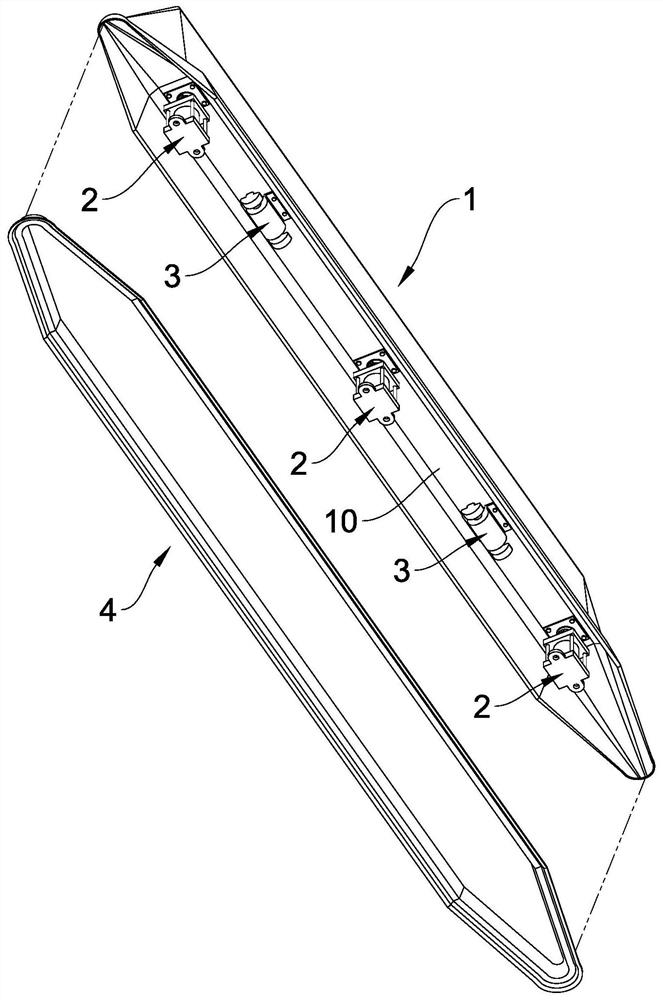

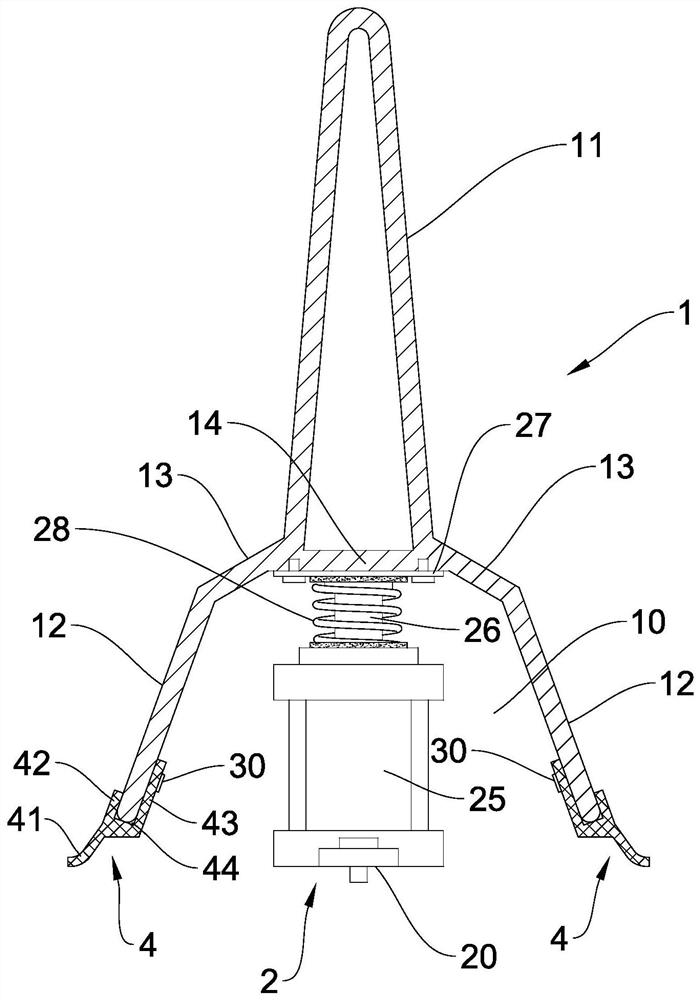

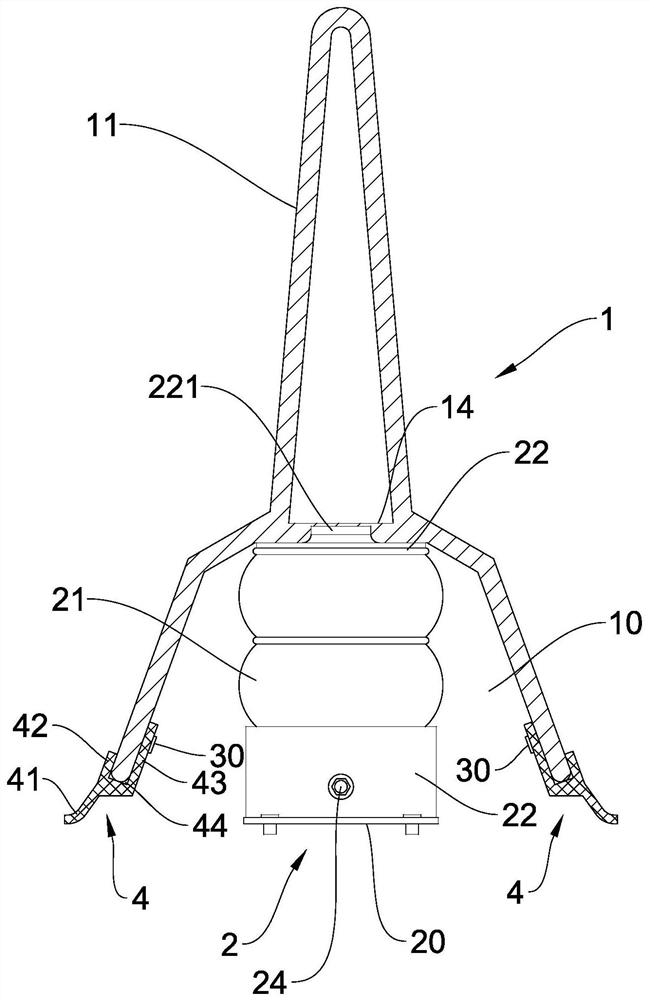

[0016] Such as Figure 1 to Figure 3 As shown, an ultrasonic airflow cutting drag reducing device for a vehicle comprises: an airflow cutting blade assembly 1, a shock absorbing installation assembly 2, an ultrasonic vibrating element 3, and a sealing rubber ring assembly 4; wherein, the airflow cutting blade assembly 1 It is an elongated piece with a narrow top and a wide bottom, and an accommodating cavity 10 is also provided on the bottom surface along its length direction. The top of the shock-absorbing mounting assembly 2 is fixedly connected to the inner cavity wall of the accommodation cavity 10, and a mounting and fixing bottom 20 is formed at the bottom of the shock-absorbing mounting assembly 2, and the mounting and fixing bottom 20 is used for connecting with the vehicle. Surface phase fixed installation, available as Figure 4 shown. Through the application of the shock-absorbing installation assembly, the ultrasonic vibrating element 3 of the present invention h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com