Diatomic boron modified molybdenum disulfide nano material and preparation method and application thereof

A molybdenum disulfide, nanomaterial technology, applied in molybdenum sulfide, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve problems such as inability to accurately introduce boron atoms and double boron atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

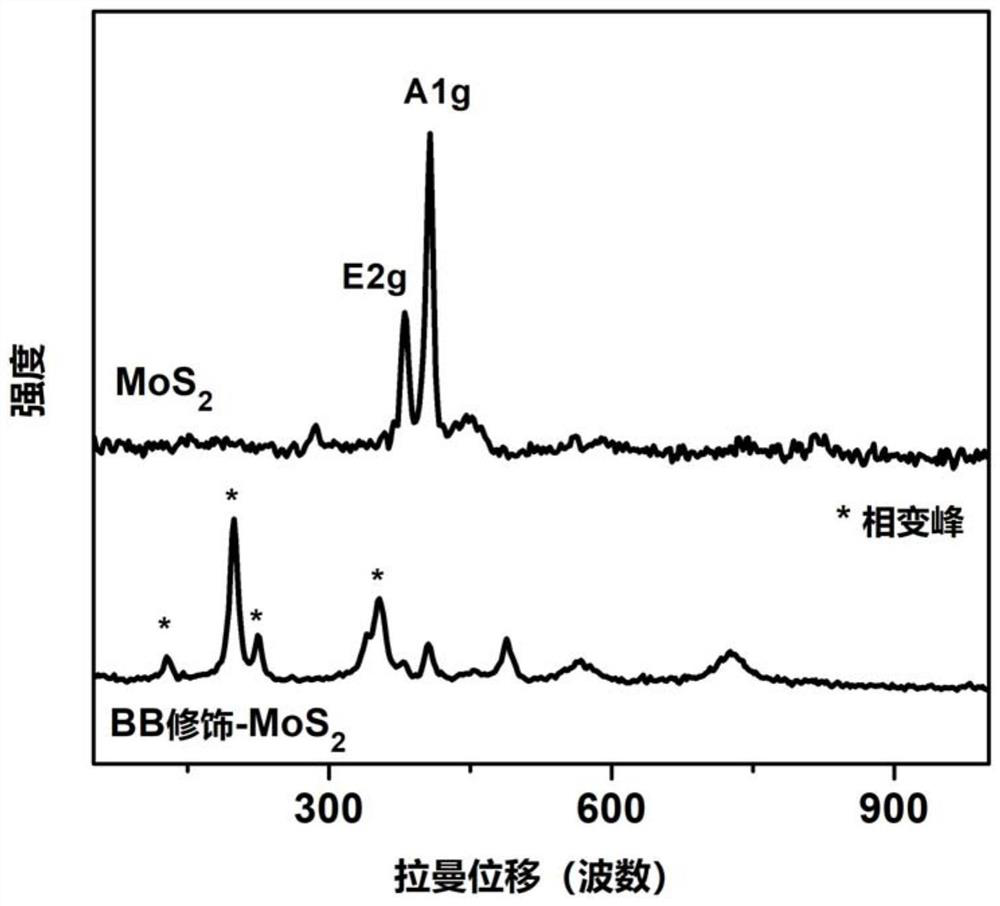

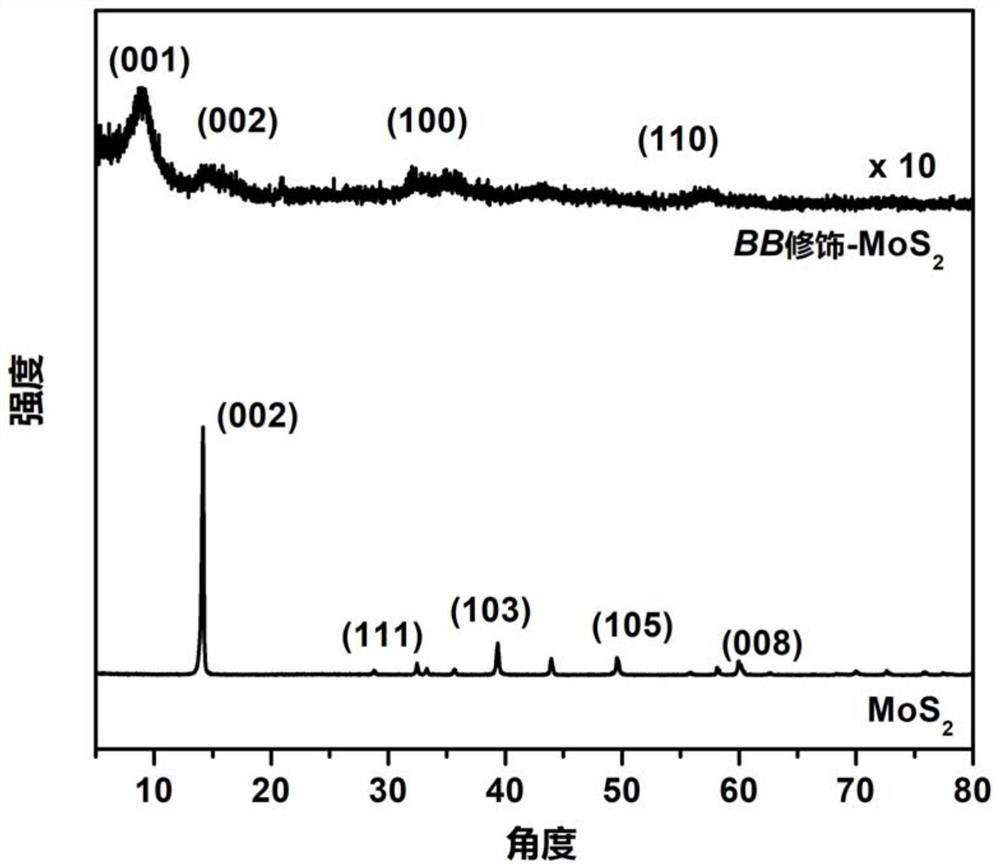

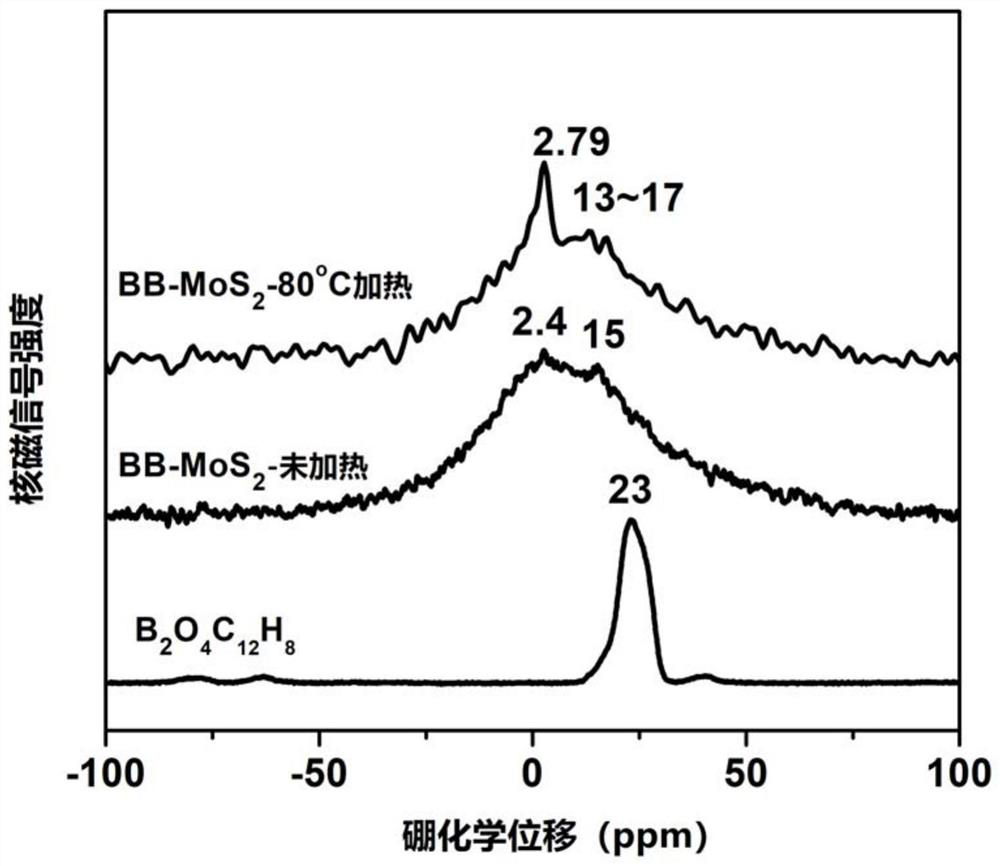

[0033] 1 g of nano-MoS 2The powder was dispersed in 100 mL of n-butyllithium cyclohexane solvent, and heated at 80° C. for 2 days in an Ar atmosphere protection condition. Then cleaned by distilled water and sonicated for 1 h, the exfoliated nano single-layer or few-layer MoS 2 nanomaterials. Subsequently, 100 mg of exfoliated MoS 2 Disperse in methanol solvent, add 200mg C 12 h 8 B 2 o 4 , heated at 80 °C for 8 h in an Ar atmosphere protection condition, and then washed the obtained product with ethanol to obtain double B atom-modified MoS 2 Material.

[0034] Boron-doped MoS obtained by 2 The modification was carried out on the glassy carbon electrode for electrocatalytic water splitting reaction test, and the results showed that the electrocatalytic effect was better than that of unmodified MoS 2 better electrocatalytic performance. Electrochemical performance test results show that boron-doped MoS 2 The electrochemical water-splitting activity was significantly ...

Embodiment 2

[0037] 1 g of nano-MoS 2 The powder was dispersed in 100 mL of n-butyllithium cyclohexane solvent, and heated at 80° C. for 2 days in an Ar atmosphere protection condition. Then cleaned by distilled water and sonicated for 1 h, the exfoliated nano single-layer or few-layer MoS 2 nanomaterials. Subsequently, 100 mg of exfoliated MoS 2 Disperse in methanol solvent, add 100mg C 12 h 8 B 2 o 4 , heated at 80°C for 10 h in an Ar atmosphere protection condition, and then washed the obtained product with ethanol to obtain double B atom-modified MoS 2 Material.

Embodiment 3

[0039] 1 g of nano-MoS 2 The powder was dispersed in 100 mL of n-butyllithium cyclohexane solvent, and heated at 80° C. for 2 days in an Ar atmosphere protection condition. Then cleaned by distilled water and sonicated for 1 h, the exfoliated nano single-layer or few-layer MoS 2 nanomaterials. Subsequently, 20 mg of exfoliated MoS 2 Disperse in methanol solvent, add 200mg C 12 h 8 B 2 o 4 , heated at 80°C for 2 h in an Ar atmosphere protection condition, and then washed the obtained product with ethanol to obtain double B atom-modified MoS 2 Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com