Long-life rust-proof recycled concrete

A technology of recycled concrete and longevity, applied in the field of concrete, can solve the problems such as the corrosion of steel bars of recycled concrete, and achieve the effect of improving the effect of grinding aid and improving the fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

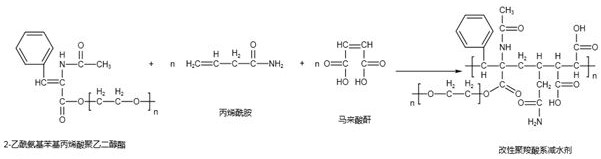

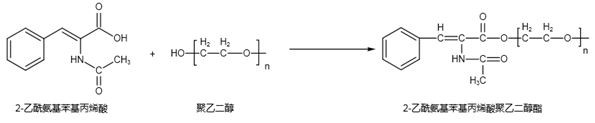

Method used

Image

Examples

Embodiment 1

[0059] A method for preparing high-life antirust recycled concrete, comprising the following steps:

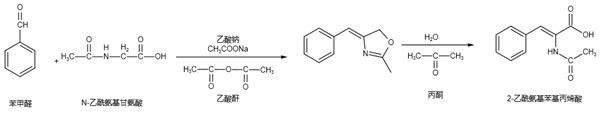

[0060] S1. Add 52g of N-acetylaminoglycine and 36g of sodium acetate into 47g of benzaldehyde solution and 45g of acetic anhydride solution and mix to form a mixed solution.

[0061] S2. Distill the mixed solution of S1 at 120° C. and 110 KPa for 4 hours, collect the reflux liquid, cool the reflux liquid to room temperature, and filter to obtain the crude product solid of 2-acetamidophenylacrylic acid, and wash the crude product solid with cold water.

[0062] S3. Dissolve the washed crude 2-acetamidophenylacrylic acid in 350g of acetone, add 120g of water to prepare a mixed solution, distill the mixed solution at 100°C and 110KPa for 4 hours, and collect the reflux. After the reflux liquid was cooled, it was filtered to obtain acetone-containing solid, and the acetone-containing solid was dried in an oven at 120°C for 8 hours to obtain 2-acetamidophenylacrylic acid solid.

...

Embodiment 2

[0070] A method for preparing high-life antirust recycled concrete, comprising the following steps:

[0071] S1. Add 43g of N-acetylaminoglycine and 30g of sodium acetate into 39g of benzaldehyde solution and 37g of acetic anhydride solution and mix to form a mixed solution.

[0072] S2. Distill the mixed solution of S1 at 110° C. and 100 KPa for 3.5 h, collect the reflux liquid, cool the reflux liquid to room temperature, and filter to obtain the crude product solid of 2-acetamidophenylacrylic acid, and wash the crude product solid with cold water.

[0073] S3. Dissolve the washed crude 2-acetamidophenylacrylic acid in 325g of acetone, add 110g of water to prepare a mixed solution, distill the mixed solution at 90°C and 100KPa for 3.5h, and collect the reflux. After the reflux liquid was cooled, it was filtered to obtain acetone-containing solid, and the acetone-containing solid was dried in an oven at 115°C for 7 hours to obtain 2-acetamidophenylacrylic acid solid.

[0074]...

Embodiment 3

[0081] A method for preparing high-life antirust recycled concrete, comprising the following steps:

[0082] S1. Add 35g of N-acetylaminoglycine and 24g of sodium acetate into 31g of benzaldehyde solution and 30g of acetic anhydride solution and mix to form a mixed solution.

[0083] S2. Distill the mixed solution in S1 at 100°C and 90KPa for 3 hours, collect the reflux liquid, cool the reflux liquid to room temperature, and filter to obtain the crude product solid of 2-acetamidophenylacrylic acid, and wash the crude product solid with cold water.

[0084] S3. Dissolve the washed crude 2-acetamidophenylacrylic acid in 300g of acetone, add 100g of water to prepare a mixed solution, distill the mixed solution at 80°C and 90KPa for 3 hours, and collect the reflux. After the reflux liquid was cooled, it was filtered to obtain acetone-containing solid, and the acetone-containing solid was dried in an oven at 110°C for 6 hours to obtain 2-acetamidophenylacrylic acid solid.

[0085]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com