Novel thermal insulation wall body and construction method thereof

A new type of technology for thermal insulation walls, applied in thermal insulation, construction, building components, etc., can solve the problems of ineffective heat insulation, poor use safety, and low strength of thermal insulation walls, so as to avoid heat loss and thermal insulation Good performance and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

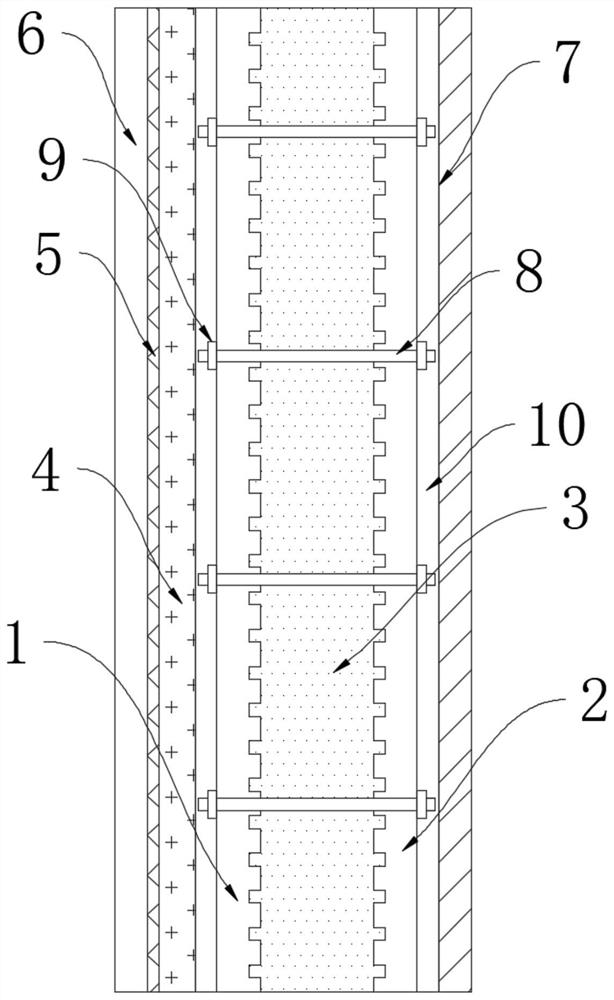

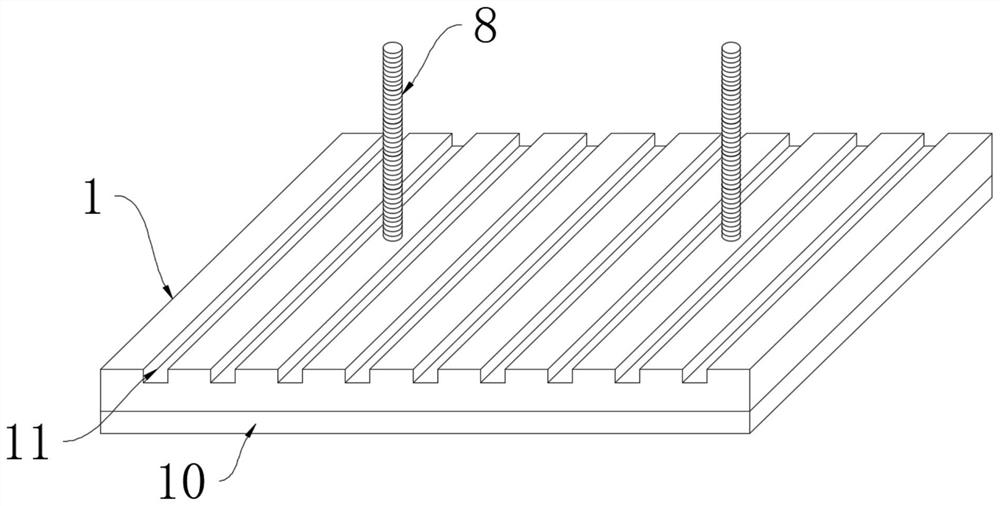

[0028] Such as Figure 1-2 As shown, the present invention provides a technical solution: a new type of thermal insulation wall, including a first flame retardant board 1, a second flame retardant board 2 and a thermal insulation filler 3, the first flame retardant board 1, the second flame retardant board There is a gap between the boards 2, and the thermal insulation filler 3 is poured in the gap between the first flame-retardant board 1 and the second flame-retardant board 2, and a plaster layer 4 is provided on one side of the first flame-retardant board 1 , the surface of the plastering layer 4 is laid with a reinforcement net 5 , the surface of the reinforcement net 5 is provided with an inner decorative surface layer 6 , and one side of the second flame-retardant board 2 is provided with an outer decorative surface layer 7 .

[0029] In this embodiment, specifically: the first flame retardant board 1 and the second flame retardant board 2 are equipped with a reinforcing...

Embodiment 2

[0041] Such as Figure 1-2 Shown, a kind of construction method of novel insulation wall, comprises the steps:

[0042] S1. Pre-embedded flame-retardant panels: pre-buried the first flame-retardant panel 1 and the second flame-retardant panel 2 in the ground, fixed the first flame-retardant panel 1 and the second flame-retardant panel 2, and 1. There is a certain gap between the second flame-retardant boards 2; the fixing screw 8 runs through the first flame-retardant board 1 and the second flame-retardant board 2, and lock nuts 9 are connected to both ends of the fixing screw 8, so that the Fixing between the first flame retardant board 1 and the second flame retardant board 2;

[0043] Step 2. Raw materials for thermal insulation filler 3: 150 parts of cement, 80 parts of gypsum, 50 parts of fly ash, 80 parts of organic silicon, 30 parts of expanded perlite, 10 parts of glass fiber, 10 parts of asbestos fiber, and 15 parts of diatomaceous earth , 8 parts of ceramic cotton ...

Embodiment 3

[0048] Such as Figure 1-2 Shown, a kind of construction method of novel insulation wall, comprises the steps:

[0049] S1. Pre-embedded flame-retardant panels: pre-buried the first flame-retardant panel 1 and the second flame-retardant panel 2 in the ground, fixed the first flame-retardant panel 1 and the second flame-retardant panel 2, and 1. There is a certain gap between the second flame-retardant boards 2; the fixing screw 8 runs through the first flame-retardant board 1 and the second flame-retardant board 2, and lock nuts 9 are connected to both ends of the fixing screw 8, so that the Fixing between the first flame retardant board 1 and the second flame retardant board 2;

[0050] Step 2. Raw materials for thermal insulation filler 3: 200 parts of cement, 20 parts of gypsum, 40 parts of fly ash, 70 parts of organic silicon, 25 parts of expanded perlite, 14 parts of glass fiber, 13 parts of asbestos fiber, and 25 parts of diatomaceous earth , 12 parts of ceramic cotton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com