Parts, plasma device, method for forming corrosion-resistant coating and device therefor

A corrosion-resistant coating, plasma technology, applied in the direction of coating, ion implantation plating, metal material coating process, etc., can solve the problem that the service life is less than expected and has to be replaced or refurbished, increasing operating costs, coating Cracking and other problems, to avoid the preferential corrosion phenomenon of the boundary, prolong the service life, and achieve the effect of consistent corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] As mentioned in the background art, the existing corrosion-resistant coatings are prone to particle pollution, and are prone to cracking and falling off. For this reason, the present invention is dedicated to providing a kind of corrosion-resistant coating, and described corrosion-resistant coating is denser, and is difficult for cracking, and corrosion resistance is stronger, and is difficult to form particle pollution, and is described in detail below:

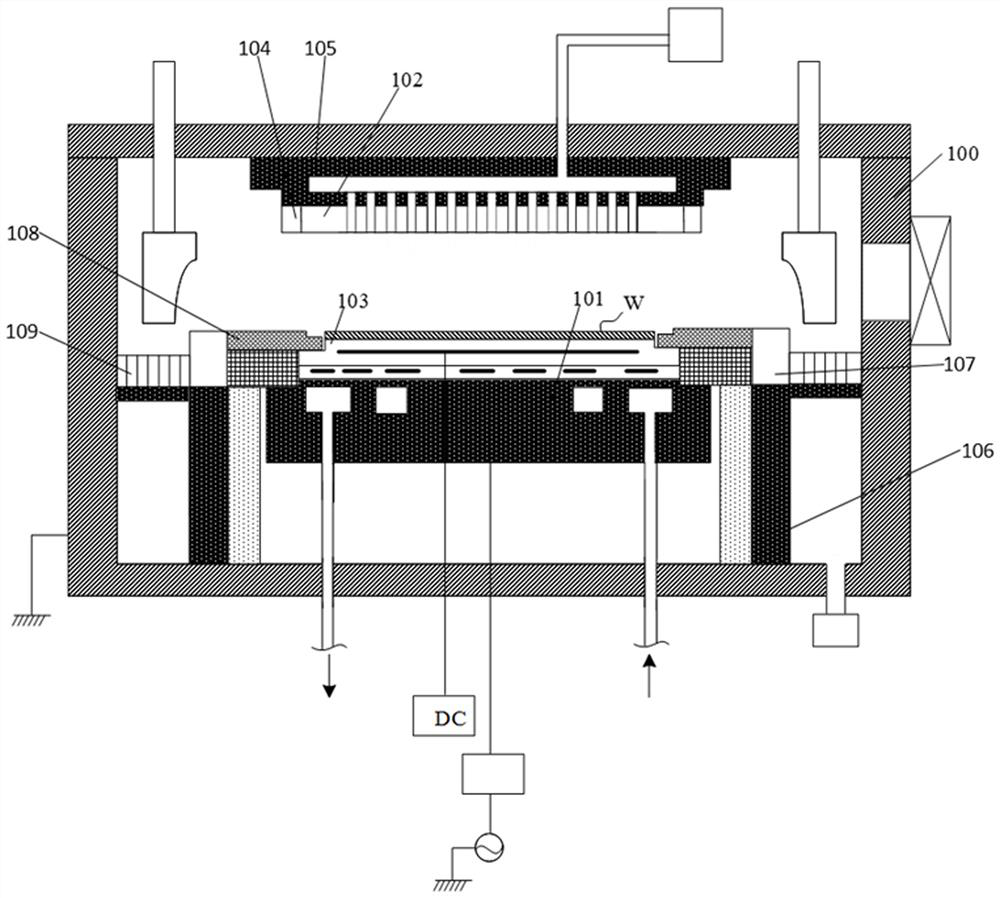

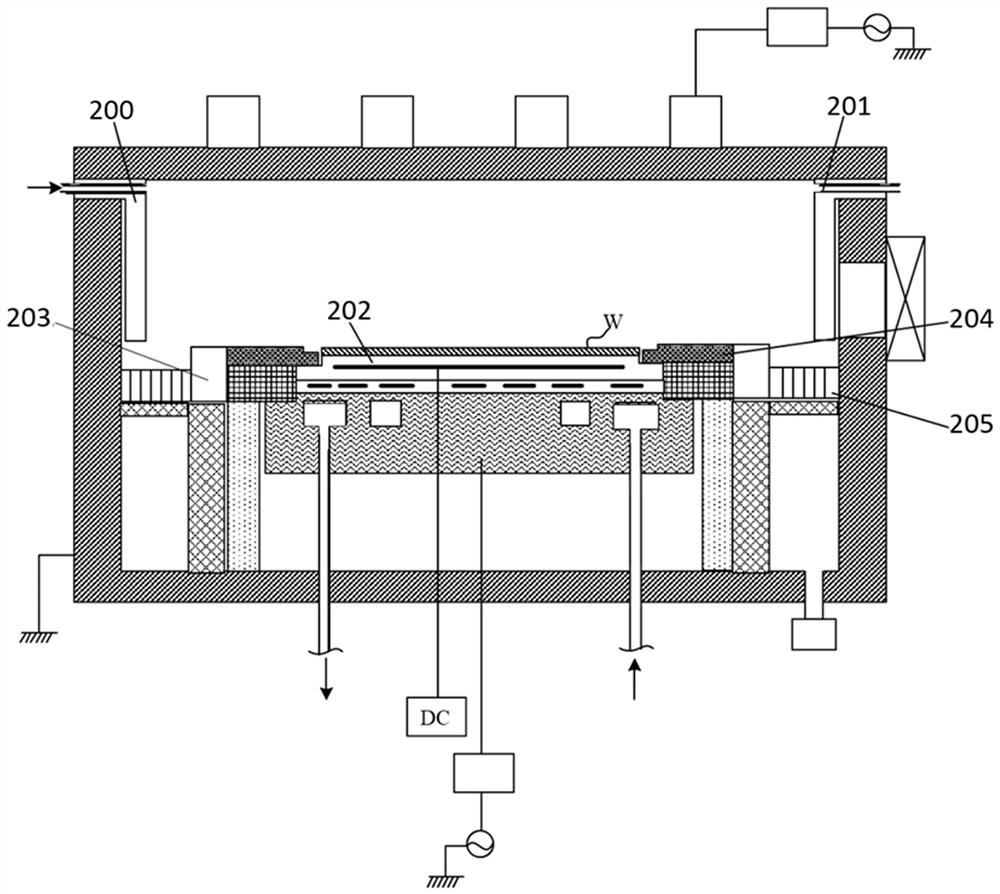

[0050] figure 1 It is a structural schematic diagram of a plasma device of the present invention.

[0051] Please refer to figure 1 , The plasma device includes: a plasma processing chamber 100, the plasma processing chamber 100 is a plasma environment, the semiconductor parts and the inner wall of the plasma processing chamber 100 are exposed to the plasma environment, and the plasma includes F-containing plasma , at least one of Cl-containing plasma, H-containing plasma, or O-containing plasma.

[0052] The plasm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com