A new energy vehicle battery control circuit board packaging equipment

A technology for new energy vehicles and packaging equipment, applied in printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve the problems of low packaging and testing efficiency, difficult production and application, and damaged circuit components, so as to reduce pollution and The risk of damage, guaranteed performance, and the effect of accelerating packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

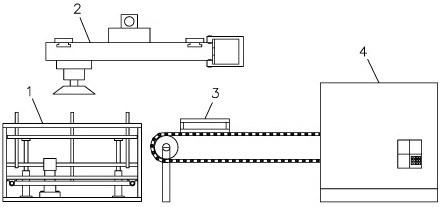

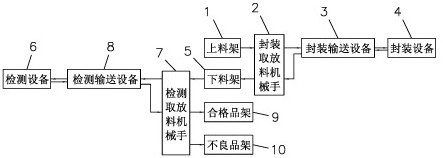

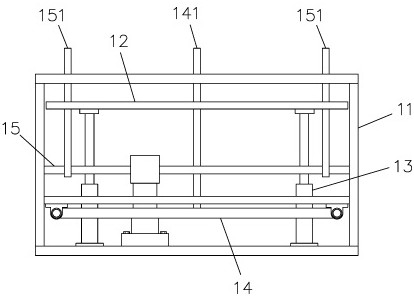

[0025] Such as Figure 1 to Figure 8 As shown, this embodiment discloses a packaging device for a new energy vehicle battery control circuit board, including a loading rack 1 for placing a circuit board to be packaged, and a loading rack 1 for picking and placing a circuit board to be packaged. Go to the packaging and conveying equipment 3 and take the packaged circuit board from the packaging and conveying equipment 3 to the packaging pick-and-discharge manipulator 2 of the unloading rack 5, which is used to transport the circuit board to be packaged into the packaging equipment 4 and package it. The encapsulation delivery equipment 3 that the circuit board is sent out from the encapsulation equipment 4, the encapsulation equipment 4 that is used to encapsulate the circuit board and the unloading rack 5 that is used to place the encapsulated circuit board, the material loading rack 1, the encapsulation conveyance The equipment 3 and the packaging equipment 4 are arranged hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com