Preparation method of chitosan/reduced graphene oxide aerogel

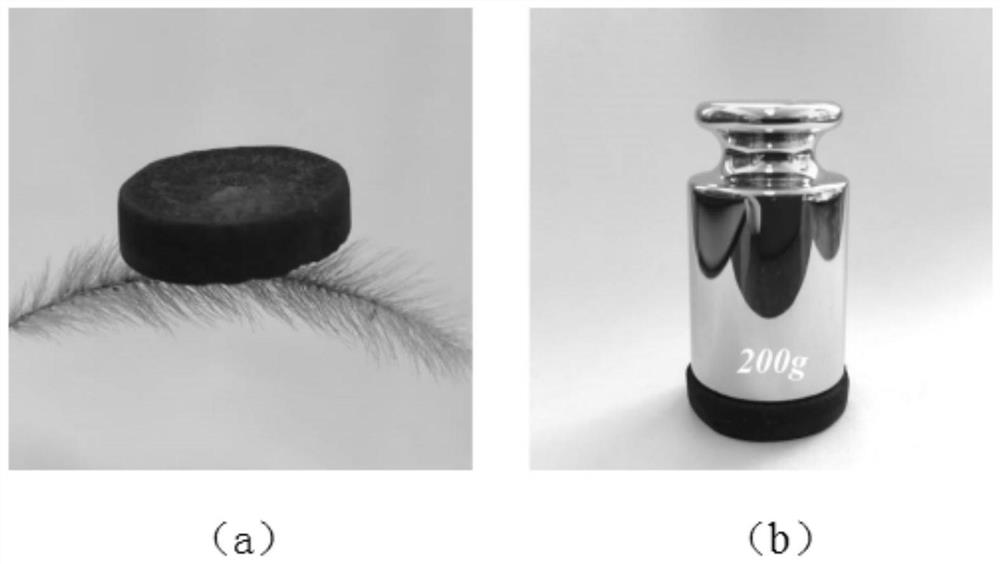

A graphene aerogel, chitosan technology, applied in chemical instruments and methods, colloidal chemistry, colloidal chemistry and other directions, can solve the problems of small pore size, difficult to control shape, uncontrollable aerogel shape, etc. High strength, cost saving, good reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

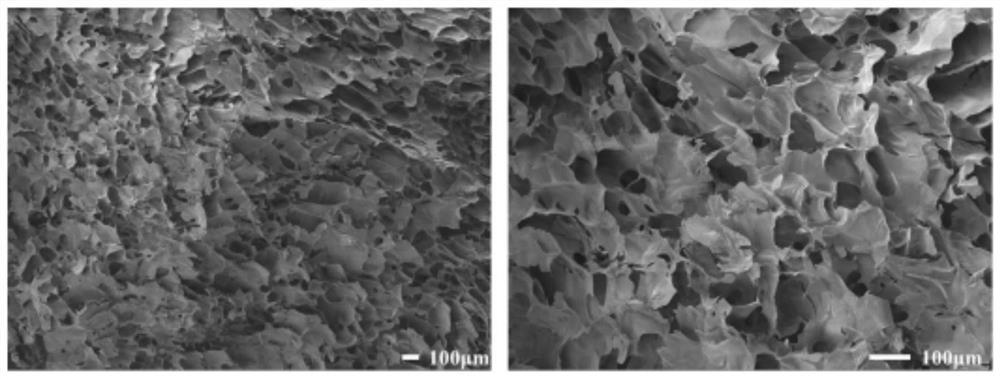

Examples

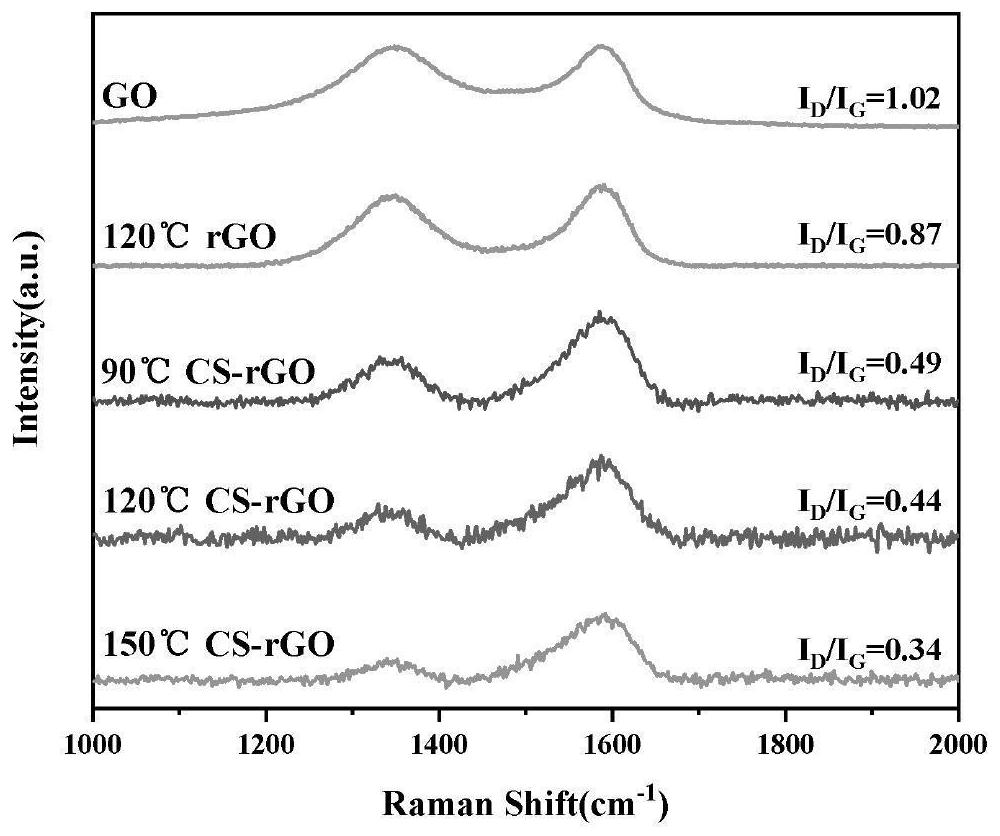

Embodiment 1

[0037] Step 1. Add 0.04g graphene oxide to 10ml distilled water, and ultrasonicate for 30 minutes at room temperature to obtain graphene oxide suspension A1;

[0038] Step 2. 0.375g chitosan is added in batches to the graphene oxide suspension A1 stirred at 700r / min, kept stirring at room temperature for 2h, to obtain graphene oxide / chitosan suspension B1;

[0039] Step 3. Gradually drop 0.3ml of acetic acid into the graphene oxide / chitosan suspension B1, the chitosan dissolves rapidly, and the system becomes a high-viscosity solution C1;

[0040] Step 4. Transfer the high viscosity solution C1 into the Teflon liner;

[0041] Step 5. Put the polytetrafluoroethylene liner into the reactor and undergo a hydrothermal reaction at 90°C for 9 hours to obtain the chitosan / reduced graphene oxide solution D1.

[0042] Step 6. Chitosan / reduced graphene oxide solution D1 is cooled to normal temperature and put into the refrigerator for pre-freezing;

[0043] Step 7. Freeze-dry the pre-...

Embodiment 2

[0045] Step 1. Add 0.04g graphene oxide to 10ml distilled water, and ultrasonicate for 30 minutes at room temperature to obtain graphene oxide suspension A2;

[0046] Step 2. 0.375g chitosan is added in batches in the graphene oxide suspension A2 that 800r / min stirs, keep stirring 2h at room temperature, obtain graphene oxide / chitosan suspension B2;

[0047] Step 3. Gradually drop 0.3ml of acetic acid into the graphene oxide / chitosan suspension B2, the chitosan dissolves rapidly, and the system becomes a high-viscosity solution C2.

[0048] Step 4. Transfer the high viscosity solution C2 into the Teflon liner;

[0049] Step 5. Put the polytetrafluoroethylene liner into the reactor and undergo a hydrothermal reaction at 120° C. for 9 hours to obtain chitosan / reduced graphene oxide solution D2.

[0050] Step 6. Chitosan / reduced graphene oxide solution D2 is cooled to normal temperature and put into the refrigerator for pre-freezing;

[0051] Step 7. Freeze-dry the pre-frozen s...

Embodiment 3

[0053] Step 1. Add 0.04g graphene oxide to 10ml distilled water, and ultrasonicate for 30 minutes at room temperature to obtain graphene oxide suspension A3;

[0054] Step 2. 0.375g chitosan is added in batches in the graphene oxide suspension A3 of high-speed stirring, keeps high-speed stirring 2h at room temperature, obtains graphene oxide / chitosan suspension B3;

[0055] Step 3. Gradually drop 0.3ml of acetic acid into the graphene oxide / chitosan suspension B3, the chitosan dissolves rapidly, and the system becomes a high-viscosity solution C3.

[0056]Step 4. Transfer the high viscosity solution C3 into the Teflon liner;

[0057] Step 5. Put the polytetrafluoroethylene liner into the reactor and undergo a hydrothermal reaction at 150° C. for 9 hours to obtain chitosan / reduced graphene oxide solution D3.

[0058] Step 6. Chitosan / reduced graphene oxide solution D3 is cooled to normal temperature and put into the refrigerator for pre-freezing;

[0059] Step 7. Freeze-dry t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com