Thermosetting lens composition, thermosetting lens, and manufacturing method thereof

A thermal curing and composition technology, applied in glasses/goggles, instruments, optics, etc., can solve problems such as process safety doubts, poor wear resistance and impact resistance, and easy explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0095] The preparation method of the heat-curable lens composition as described herein is to use a heat-curing program to cure for about 20-24 hours, including the following steps:

[0096] S1. The heat-curable lens composition is mixed into a glue solution according to the ratio as claimed in claim 2, and vacuum defoaming is performed to form a first mixture;

[0097] S2. injecting the first mixture into a light-transmitting mold to form a mold body, and heating the mold body to form a second mixture;

[0098] S3. performing temperature-controlled curing on the second mixture to form a heat-cured lens;

[0099] S4. Release and dry the heat-cured lens in S3, and perform secondary curing to obtain the heat-cured lens.

[0100] In another preferred example, the vacuum defoaming in S1 lasts for 30 minutes at room temperature and a pressure less than 0.1 torr.

[0101] In another preference, a demoulding step can be added after forming the second mixture;

[0102] In another pr...

Embodiment 1

[0109] Example 1. Preparation of thermosetting lenses

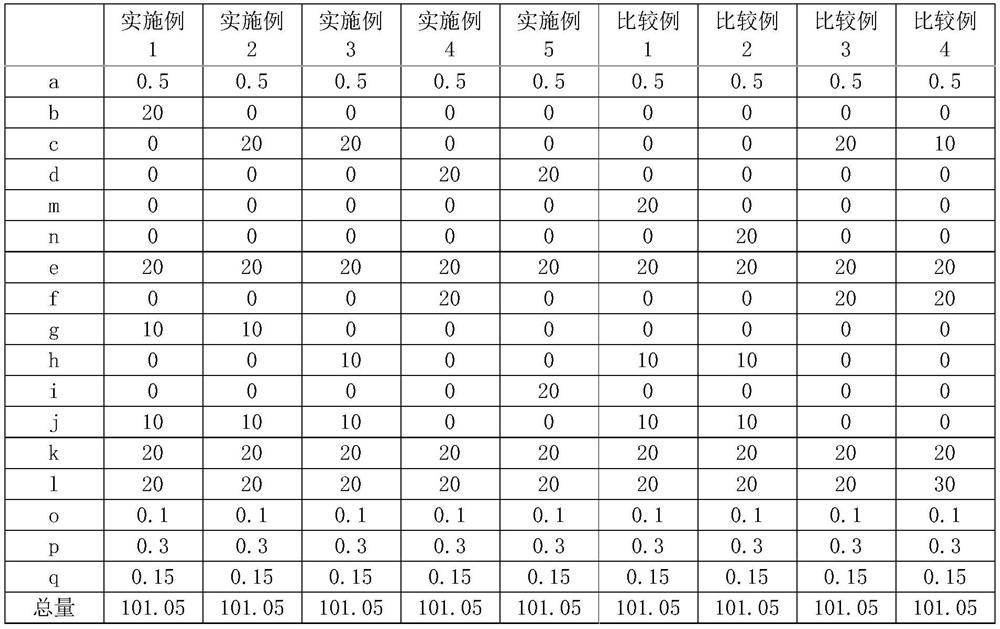

[0110] Example 1 is prepared according to the list of reagents in Table 1 and Table 2. After the reagents are mixed evenly with the listed weight parts, the obtained glue is prepared according to the following steps to prepare thermosetting lenses:

[0111] (1) Put the thermosetting lens composition into a vacuum oven at room temperature and defoam in vacuum for 30 minutes at a pressure of less than 0.1 torr to form a first mixture).

[0112] (2) injecting the first mixture into a light-transmitting mold to form a mold body, and heating the mold body to form a second mixture. The heating program used was:

[0113] First raise the temperature of the mold body from room temperature to 41°C, and heat it at 41°C for 11 hours; then raise the temperature of the mold body from 41°C to 110°C, and heat it at 110°C for 8 hours; ℃ to 55 ℃, and continue for 1 hour

[0114] (3) Perform temperature-controlled curing on the second mi...

Embodiment 2 to 5

[0117] Examples 2 to 5: Preparation of thermosetting lenses

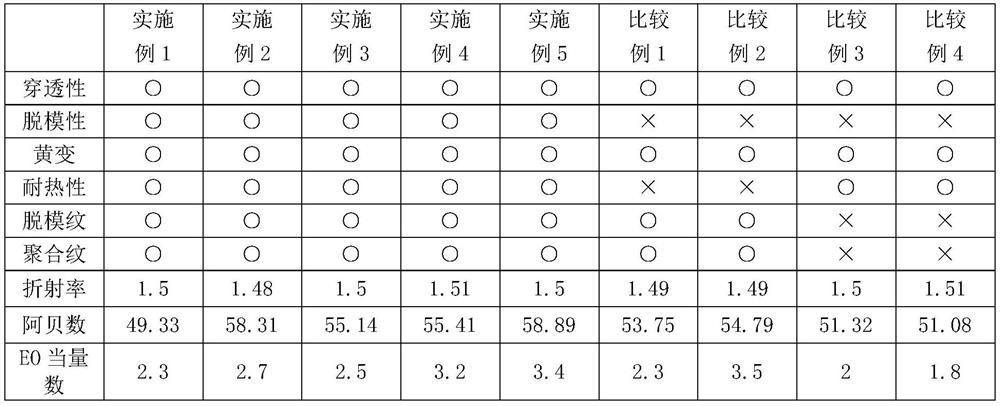

[0118] Examples 2 to 5 are based on the reagents and dosages listed in Table 1, using the same method as in Example 1 to mix evenly and carry out glue injection molding to form a mold body, and then release the mold after curing, and perform the following lenses The evaluation items, and the results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com