A kind of reaction medium of uranium-containing low-temperature molten salt system, preparation method and application of the system

A technology of low-temperature molten salt and reaction medium, which is applied in the direction of reactor fuel materials, greenhouse gas reduction, nuclear power generation, etc., can solve the problems of electrolytic cell short circuit, large-scale continuous production, etc., and achieve simple process, solve electrolytic cell short circuit, and good The effect of environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In a low-humidity hypoxic glove box, mix the components evenly according to the molar ratio LiBr: KBr: CsBr = 0.561: 0.189: 0.250, then weigh 300 g of dried LiBr, KBr and CsBr mixed salts and 6 g of ZnBr 2 , after stirring evenly, put it into an alumina crucible. In the heating furnace in the glove box, the crucible is heated to 400 °C with the heating furnace at a heating rate of 3 °C / min. During this period, 5g of high-purity dendritic metal uranium was dried and stored. When the temperature of the molten salt in the crucible reaches 240°C, the above metal uranium is added at one time. At this time, a violent substitution reaction can be observed in the crucible.

[0054] When the reaction reached 12 hours, a cold alumina rod was quickly inserted into the molten salt and then taken out. At this time, the molten salt sample adhered to the surface of the alumina rod was used for ICP-AES analysis. The analysis results showed that the content of zinc element in the mol...

Embodiment 2

[0059] In a low-humidity and low-oxygen glove box, according to the molar ratio LiBr: KBr: CsBr = 0.561: 0.189: 0.250, mix the components evenly, and then weigh 300 g of the dried LiBr, KBr and CsBr mixed salt and 10 g of ZnBr 2 , after stirring evenly, put it into an alumina crucible. In the heating furnace in the glove box, the crucible was heated to 450 °C with the heating furnace at a heating rate of 3 °C / min. During this period, 8g of high-purity dendritic metal uranium was dried and preserved. When the temperature of the molten salt in the crucible reaches 240°C, the above metal uranium is added at one time. At this time, a violent substitution reaction can be observed in the crucible.

[0060] Then, use a cold alumina rod to quickly put it into the molten salt and then take it out. At this time, the molten salt sample adhered to the surface of the alumina rod is used for ICP-AES analysis. The analysis results show that the mass fraction of zinc element in the molten ...

Embodiment 3

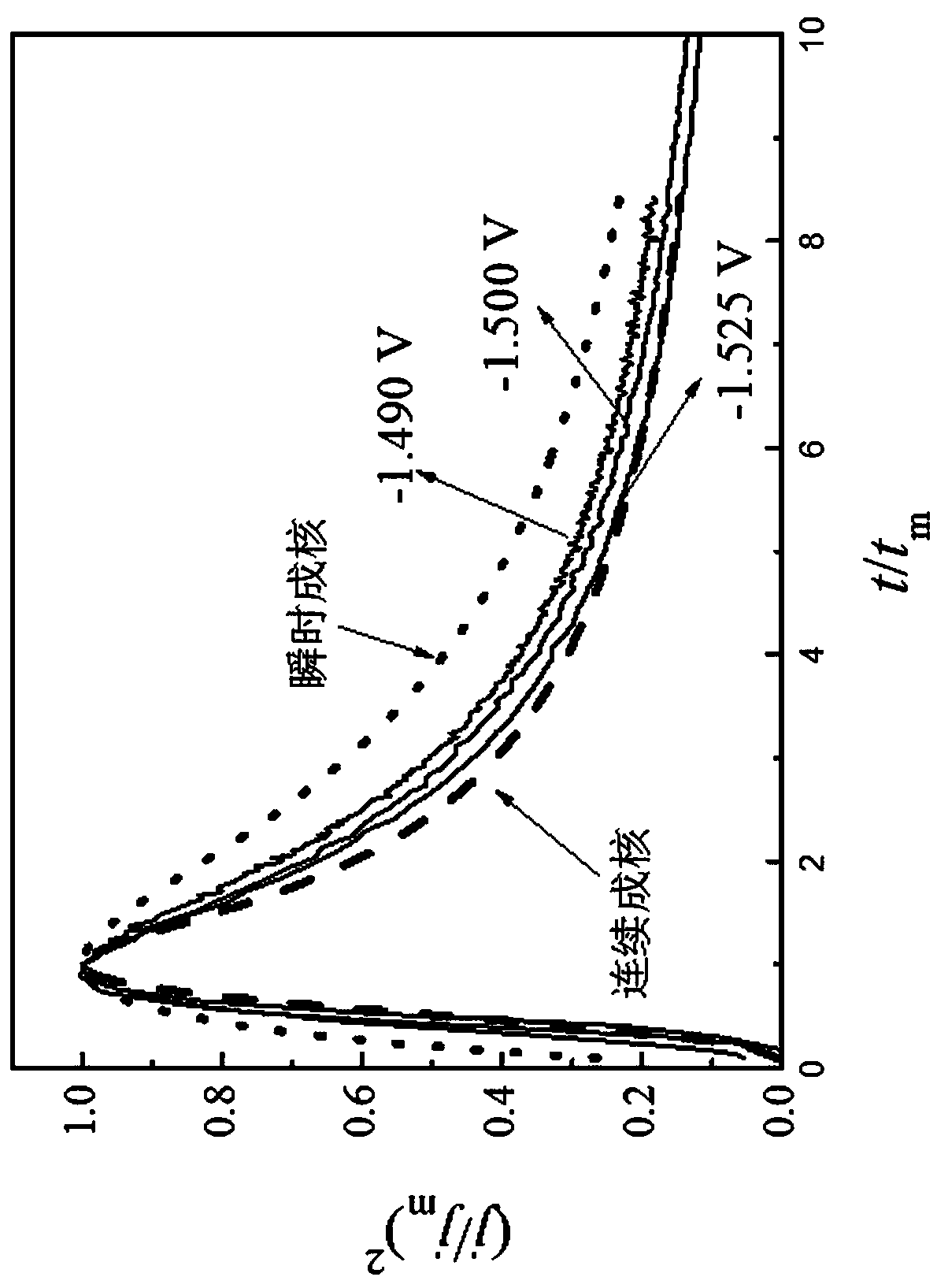

[0063] In the electrolytic furnace, with the UBr prepared according to the example 1 method 3 LiBr-KBr-CsBr-UBr with a mass fraction of 2.7% 3 The bromide molten salt system is the electrolyte, the cathode uses a tungsten rod with a diameter of 2mm and a length of 40mm immersed in the molten salt, and the anode uses a metal uranium rod with a diameter of 9mm and a length of 100mm for electrolytic refining; among them, the cell voltage is 0.7V, and the electrolysis temperature is 350 ℃, the electrolysis time is 48 hours. High-purity metal uranium is deposited on the cathode, and the metal uranium presents a nodular shape.

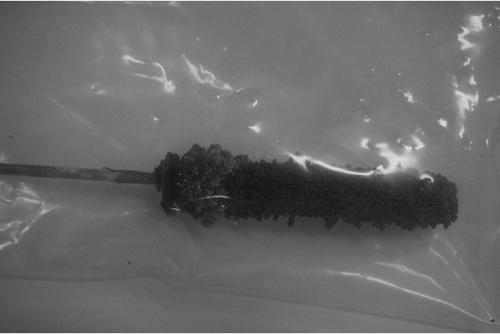

[0064] Analysis result shows: the metallic uranium purity that present embodiment prepares exceeds 99.995%, and uranium sample is as image 3 As shown, the XRD pattern of the uranium sample is as Figure 4 Shown, impurity element content analysis is shown in Table 1. image 3 In the figure, the top is the silver-white metallic uranium after the molten sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com