Thin-film solar cell

A solar cell and thin film technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of fragility, troublesome production process, inability to manufacture and process, and achieve the effect of wide selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a further understanding of the features and features of the present invention, the following preferred embodiments are now listed and described as follows in conjunction with the accompanying drawings:

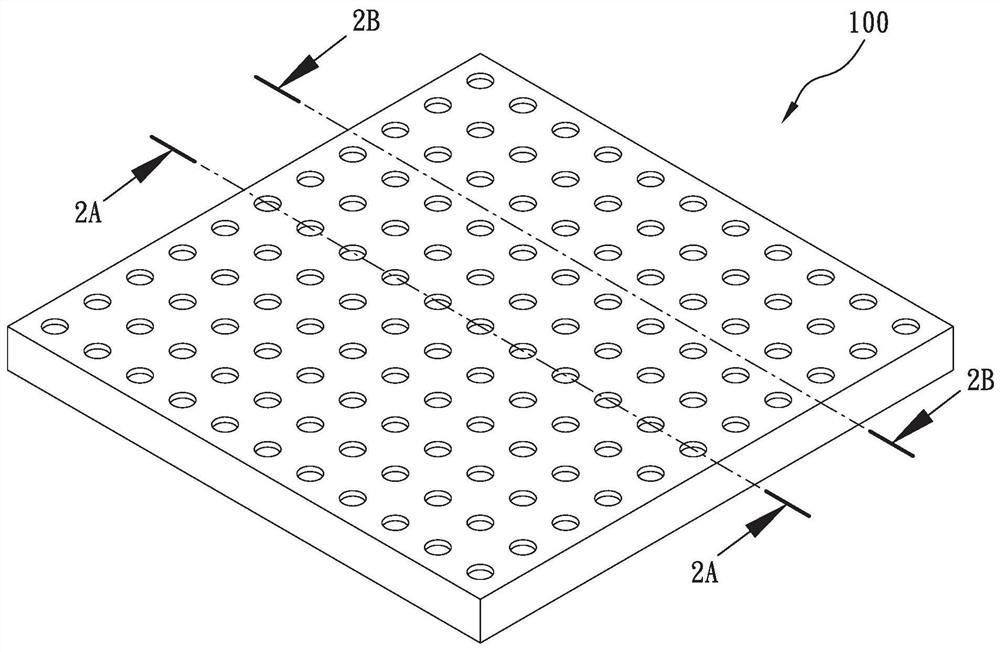

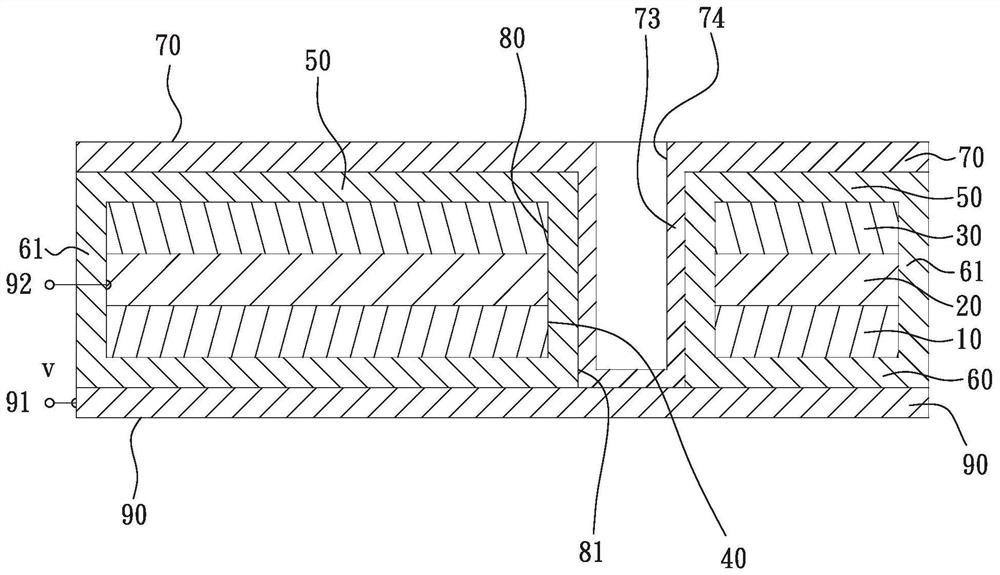

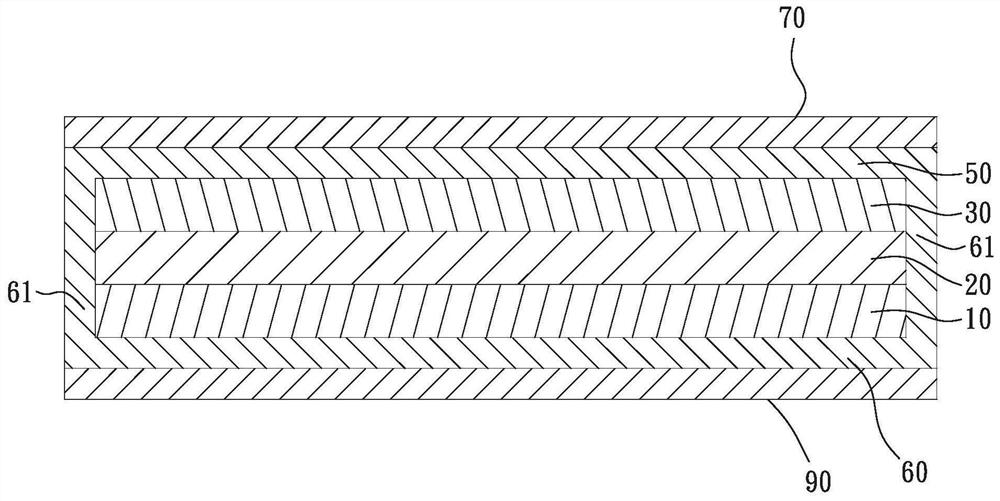

[0037] In the following examples, figure 1 There are multiple perforations 40, for ease of illustration, Fig. 2~ Figure 7 The perforation 40 in is only drawn as an example. see figure 1 2A and 2B, a preferred embodiment of the thin film solar cell 100 of the present invention includes a mirror material layer 10, a contact conductive layer 20, an NP-type semiconductor lower layer 30, a plurality of through holes 40, a NP Type semiconductor upper layer 50, an insulating layer 60, a plurality of insulators 80, a transparent conductive layer 70, a conductive substrate 90, a plurality of conductors 73 and other stacked layers and components.

[0038] see Figure 3a ~ Figure 3f Shown is a process step chart of an embodiment of the thin film solar cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com