Poly(amic acid) composition, polyimide composition and polyimide molded body

A technology of polyamic acid and composition, applied in the field of polymer compounds and polyimide moldings, can solve the problems of reduced mechanical strength and durability, and achieve the effect of excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0056]

[0057] [polyamic acid]

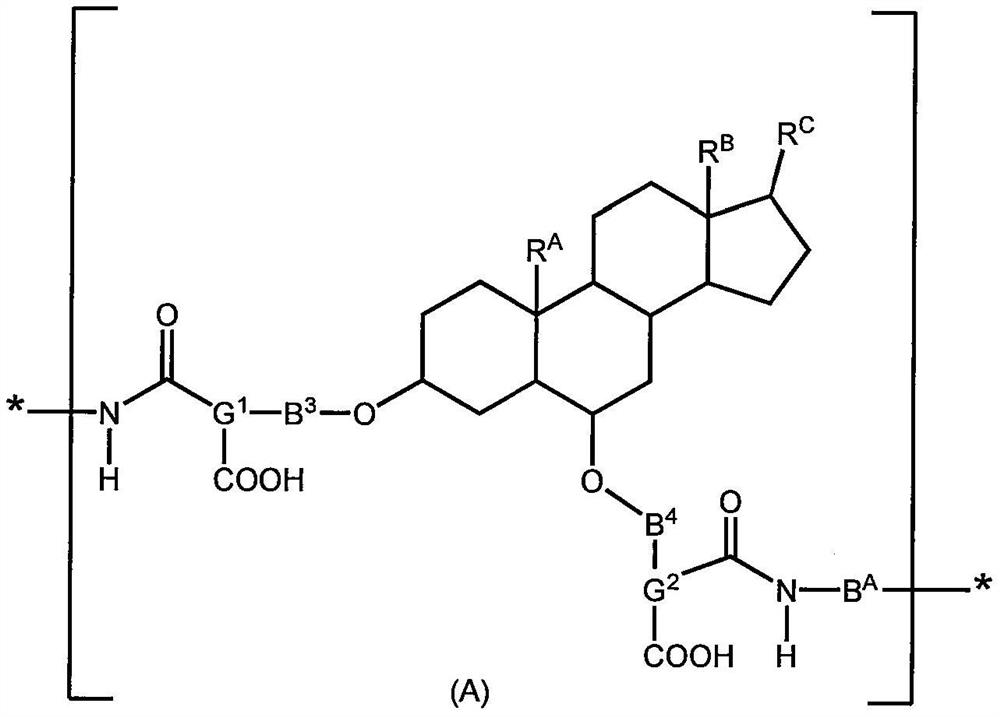

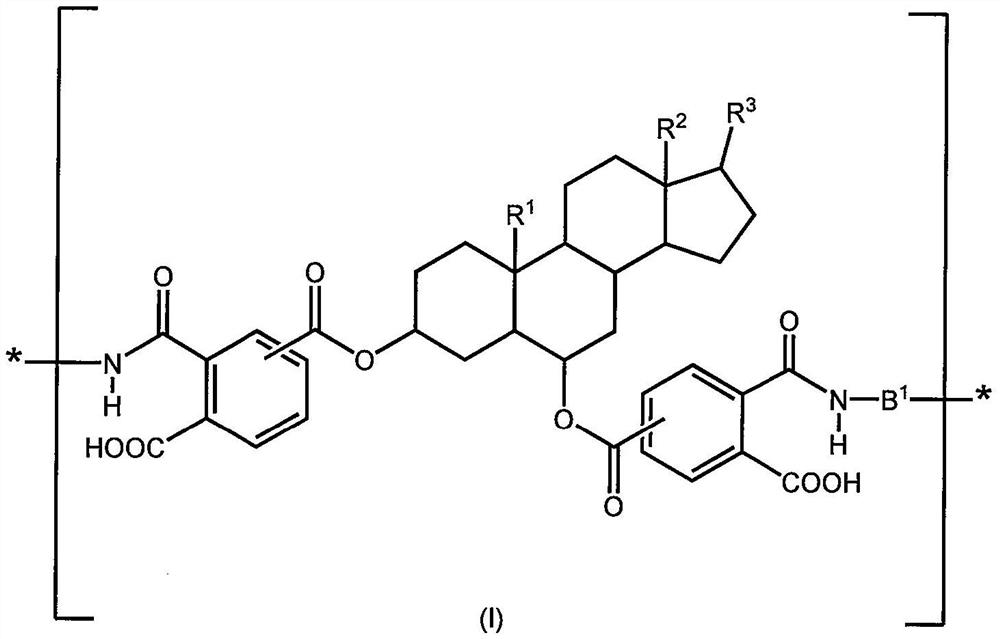

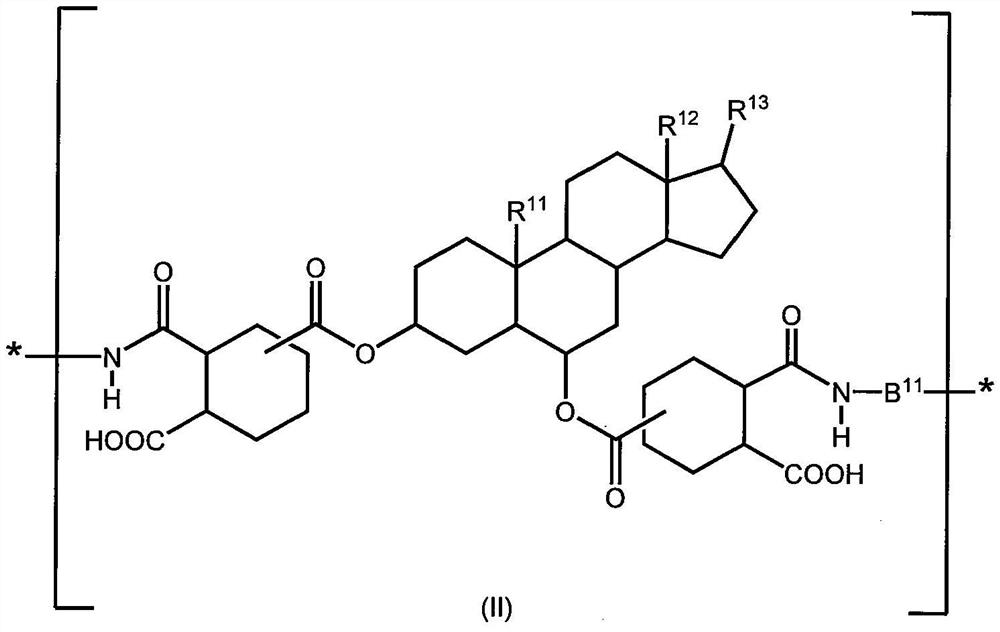

[0058] The polyamic acid composition of the first embodiment of the present invention contains polyamic acid and a solvent. The polyamic acid composition (hereinafter, sometimes referred to as "polyamic acid composition (A)") consists of a repeating unit (hereinafter, sometimes referred to as "repeating unit (A)") represented by the following general formula (A) The polyamic acid (hereinafter, sometimes described as "polyamic acid (A)") is dissolved or dispersed in a solvent.

[0059] [chemical formula 3]

[0060]

[0061] In general formula (A):

[0062] R A and R B each independently is a hydrogen atom or a methyl group;

[0063] R C is a hydrogen atom, an alkyl group with 1 to 20 carbon atoms, or an alkenyl group with 2 to 10 carbon atoms;

[0064] B A is a divalent organic group;

[0065] B 3 and B 4 each independently -C(=O)- or -CH 2 -;

[0066] G 1 and G 2 Each independently contains at least one ring selected from t...

no. 2 approach

[0269]

[0270] The polyimide composition of 2nd Embodiment of this invention contains polyimide and a solvent. The polyimide composition consists of a polyimide (hereinafter, sometimes referred to as "polyimide") comprising a repeating unit represented by the following general formula (B) (hereinafter, sometimes referred to as "repeating unit (B)"). (B)") is formed by dissolving or dispersing in a solvent.

[0271] [chemical formula 21]

[0272]

[0273] In general formula (B),

[0274] R D and R E each independently is a hydrogen atom or a methyl group;

[0275] R F is a hydrogen atom, an alkyl group with 1 to 20 carbon atoms, or an alkenyl group with 2 to 10 carbon atoms;

[0276] B D is a divalent organic group;

[0277] B 5 and B 6 each independently -C(=O)- or -CH 2 -;

[0278] G 3 and G 4 Each independently contains at least one ring selected from the group consisting of aliphatic rings and aromatic rings, or each independently linear alkanetriyl with...

no. 3 approach

[0351]

[0352] The polyimide molded article of the third embodiment of the present invention is formed by molding the polyamic acid composition of the first embodiment or the polyimide composition of the second embodiment. That is, the polyimide molded article of 3rd Embodiment contains polyimide (B) (for example, polyimide (V)-(VIII)).

[0353] This polyimide molded article is suitable for the following applications, for example, liquid crystal alignment film, passivation film, wire covering material, adhesive film, flexible electronic substrate film, copper clad laminate film, laminate film, electrical insulation film , Porous membranes for fuel cells, separation membranes, heat-resistant coatings, IC packages, resist films, planarization films, lenses such as microlens array films, optical fiber coating films, display substrates, optical waveguides, optical Filters, optical filters, adhesive sheets, interlayer insulation films, semiconductor insulation protection films, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Pencil hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com