Agent and method for suppressing dehydration condensation of silanol group, and method for manufacturing silanol-group-containing polyorganosiloxane, and composition for same

A technology of polyorganosiloxane and reaction inhibitor, which is applied in the field of manufacturing method of silanol group-containing polyorganosiloxane and its composition, can solve problems such as changes in physical properties, storage stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

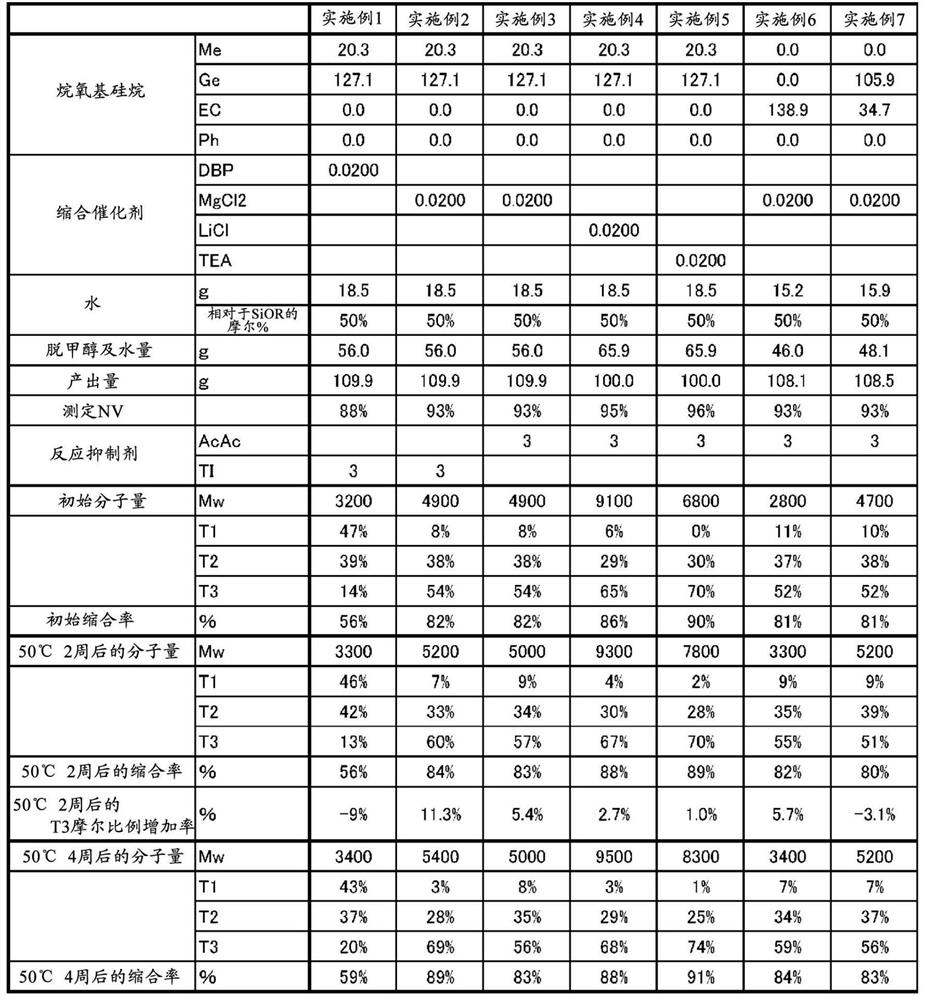

[0133] (Example 1) Synthesis of polyorganosiloxane

[0134] Add 20.3g of methyltrimethoxysilane, 127.1g of 3-glycidoxypropyltrimethoxysilane, 0.020g of dibutyl phosphate, and 18.5g of pure water to a 300ml four-necked flask, and set the temperature at 90°C heated in an oil bath and reacted for 4 hours. Then, use an evaporator and an oil bath set at 105°C to remove the generated methanol and residual water, then add 3.0 g of toluenesulfonyl isocyanate as a reaction inhibitor, stir until it becomes uniform, and obtain a silane Alcohol-based polyorganosiloxane solution 109.9 g. The NV of the obtained polyorganosiloxane was measured to be 88%, the weight average molecular weight was 3200, and the condensation rate was 50%.

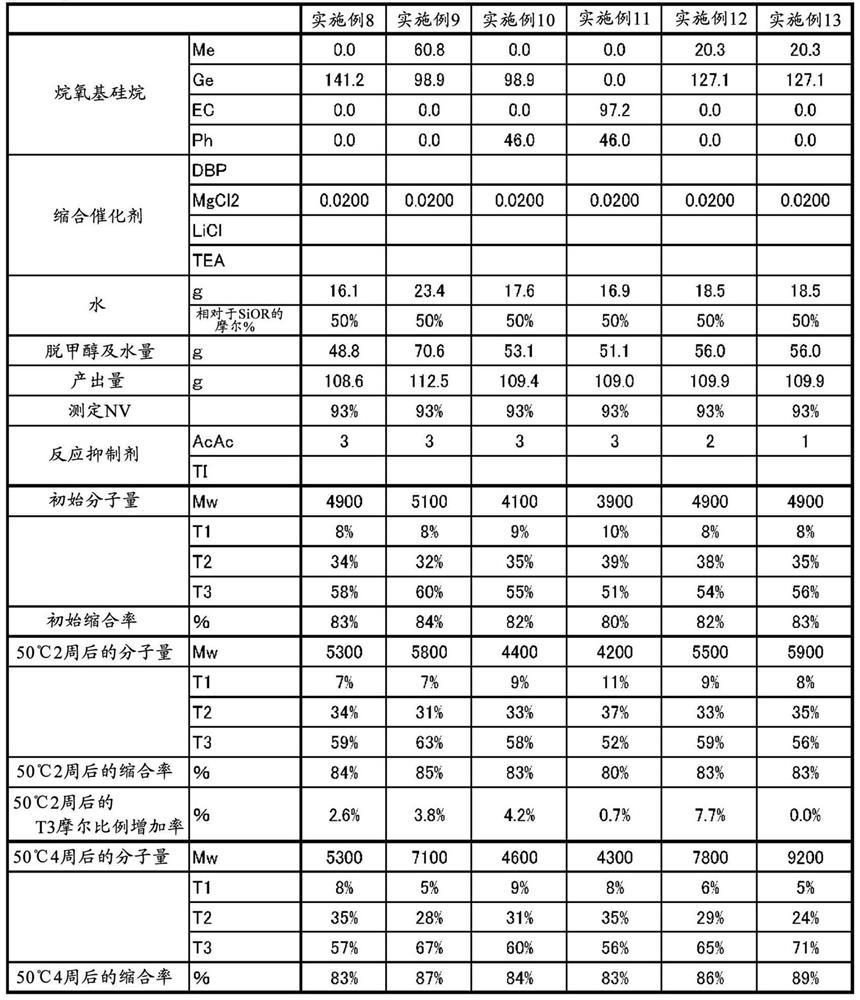

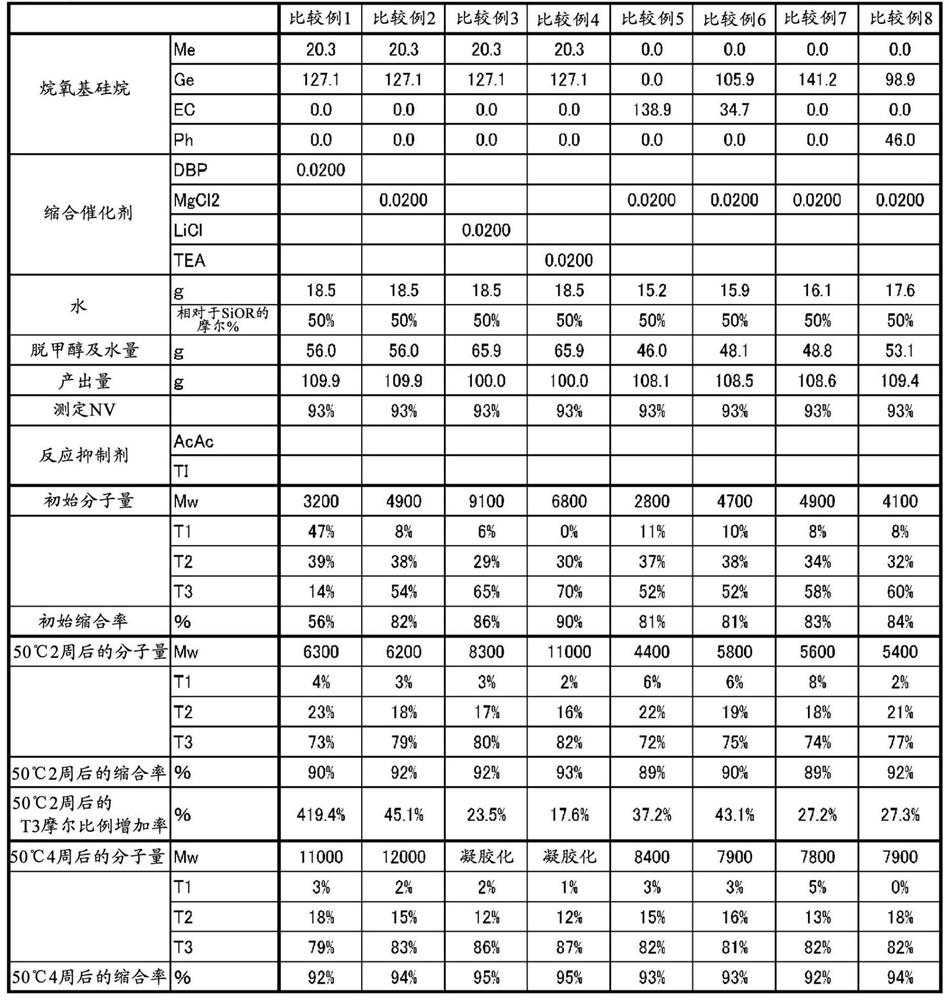

Embodiment 2~13 and comparative example 1~8

[0136] A polyorganosiloxane solution was obtained in the same manner as in Example 1 except that the amount of raw materials used and the reaction conditions were set in accordance with the descriptions in the tables. In addition, in each table|surface, the unit of the compounding quantity of each component is gram (g).

[0137] (weight average molecular weight)

[0138] The weight average molecular weight of the polyorganosiloxane was determined by GPC. GPC was performed using HLC-8320GPC manufactured by Tosoh Corporation as a liquid delivery system, TSK-GEL type manufactured by Tosoh Corporation as a column, THF as a solvent, and the weight average molecular weight was calculated in terms of polystyrene.

[0139] ( 29 Si-NMR)

[0140] Structural units derived from monoorganotrialkoxysilanes are classified into structural units T1 forming one siloxane bond, structural units T2 forming two siloxane bonds, and structural units forming three siloxane bonds T3. Using AVANCEI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com