Production method for fully separating, regenerating and recycling old gypsum boards

A production method, the technology of old gypsum board, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems affecting the purity of the finished gypsum board, difficult to separate, etc., and achieve the effect of avoiding large color difference and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

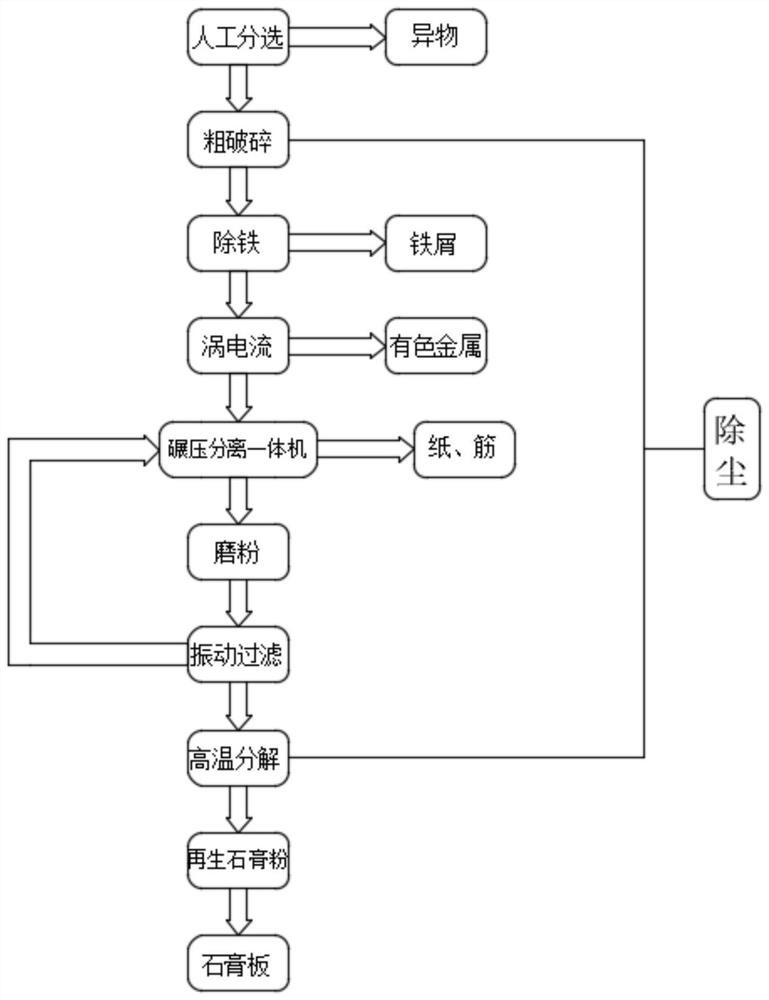

[0057] see figure 1 , the old gypsum board full separation regeneration recycling production method of an embodiment of the present invention, comprises the following steps:

[0058] S1: manual sorting;

[0059] Use the used gypsum products as raw materials, and manually sort out large-sized foreign objects; manually sorting out large-sized foreign objects first can reduce the workload of subsequent removal of debris, and can also reduce the workload of the crusher;

[0060] S2: Coarse crushing;

[0061] The gypsum raw materials after manual sorting enter the crusher for coarse crushing to obtain massive gypsum raw materials; the jaw crusher breaks large gypsum into smaller blocks to prevent metal objects or non-ferrous metals from being embedded in the gypsum, magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com