Edge closing machine for furniture processing

A furniture and workbench technology, applied in the field of furniture processing, can solve the problems of cumbersome process and labor-intensive, and achieve the effects of avoiding labor loss, improving grinding effect and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

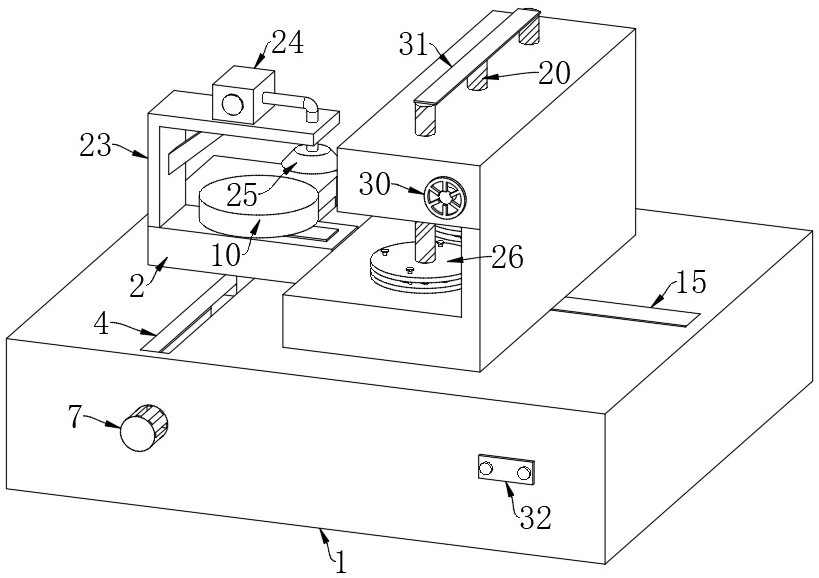

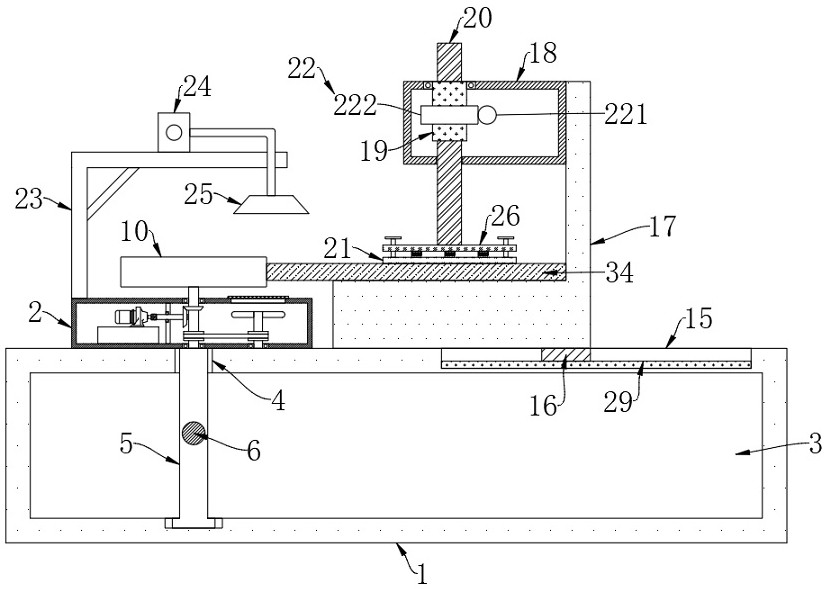

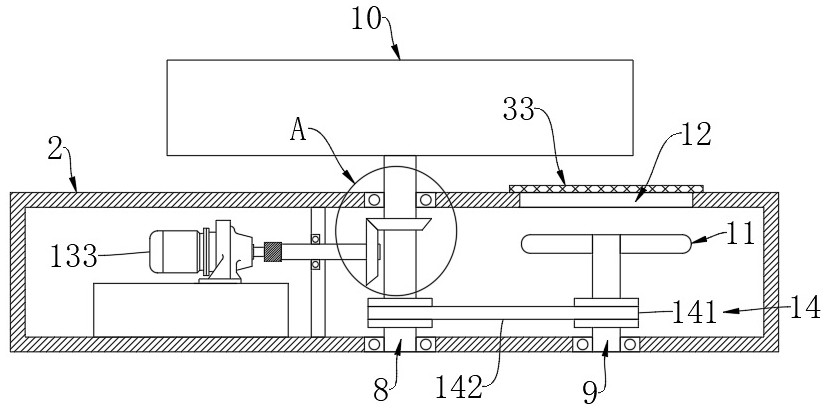

[0029] Such as Figure 1-5 As shown, an edger for furniture processing includes a workbench 1 and a drive box 2, a cavity 3 is opened on the workbench 1, and an opening chute 4 matching the cavity 3 is opened on the workbench 1 , the drive box 2 is slidably connected with the opening chute 4 through the slide bar 5, and the lower end of the slide bar 5 is slidably connected with the inner top surface of the lower end of the cavity 3, the drive box 2 is fixedly connected with a bracket 23, and the bracket 23 is provided with Vacuum cleaner 24, vacuum cleaner 24 is communicated with dust collection cover 25 by suction pipe, by the cooperation of dust collection cover 25 and vacuum cleaner 24 of setting, can coordinate the grinding process of grinding wheel 10, clean up the dust debris that produces in grinding process in time.

[0030] The cavity 3 is rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com