Epitaxial furnace purging and cooling system, method and device, electronic equipment and storage medium

A cooling system, epitaxial furnace technology, applied in chemical instruments and methods, from condensed steam, from chemically reactive gases, etc., can solve problems such as no technical solutions, decline in epitaxial wafer quality, dislocations, etc., to improve production. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

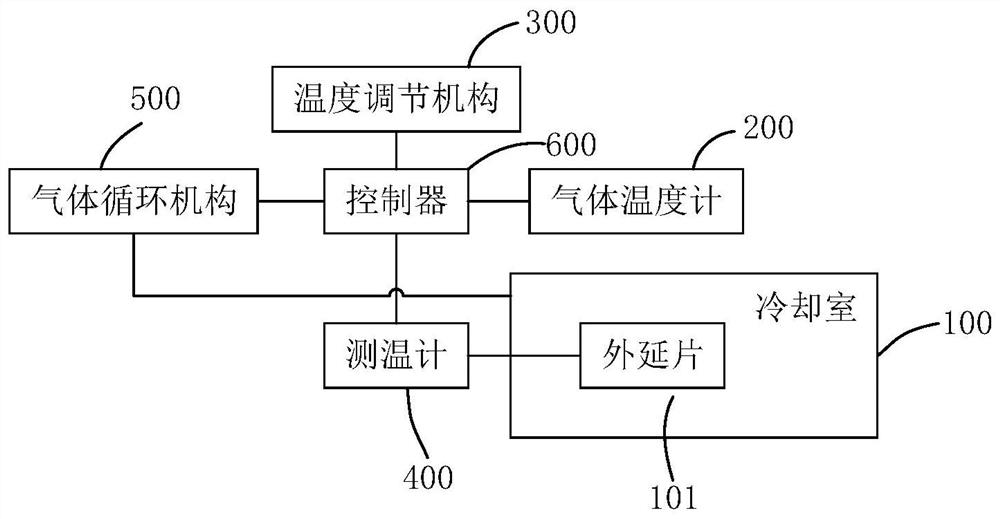

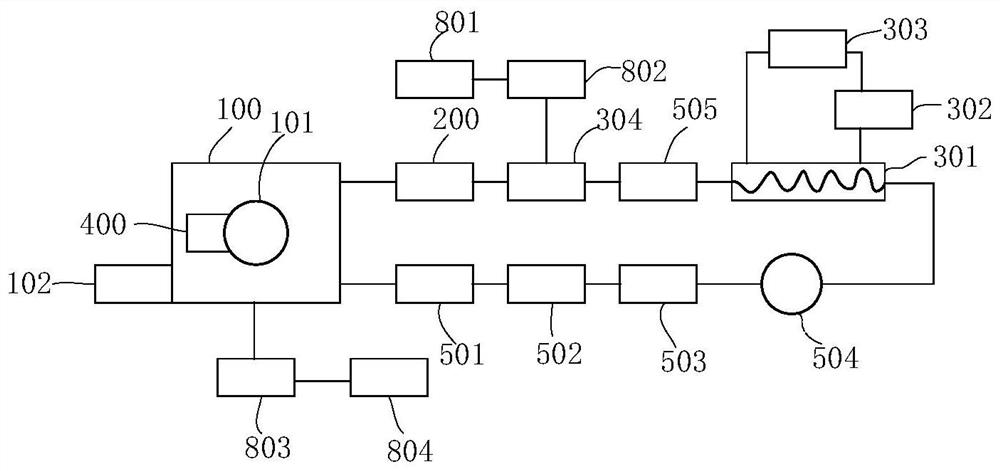

[0091] Such as figure 2 Shown is a purge cooling system for an epitaxial furnace, including a cooling chamber 100, a gas circulation mechanism 500, a gas supply mechanism 801, a heating mechanism, a cooling mechanism, a waste gas treatment mechanism, a gas thermometer 200, a thermometer 400, a tower light 102 and controller (not shown).

[0092] The cooling chamber 100 is provided with a tray for placing the epitaxial wafer 101 for purging and cooling the epitaxial wafer 101 , and the thermometer 400 is connected to the tray to obtain the temperature of the tray and the epitaxial wafer 101 .

[0093] Wherein, the gas circulation mechanism 500 includes a circulation pipeline connected to the cooling chamber 100 at both ends, and a filter 501, a first pneumatic valve 502, a flow meter 503, a circulation pump 504, and a second pneumatic valve 505 arranged in sequence on the circulation pipeline. , the gas thermometer 200 is arranged on the circulation pipeline, and is located a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com