Prefabricated concrete ground beam-shear wall connecting joint and construction method thereof

A technology of prefabricated concrete and connecting nodes, which is applied in the direction of walls, structural elements, building components, etc., can solve the problems of inability to make full use of assembly type fast and efficient, no fast and efficient detection method, insufficient tensile and shear resistance, etc., to avoid Premature cracking, avoiding tension-shear composite stress, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

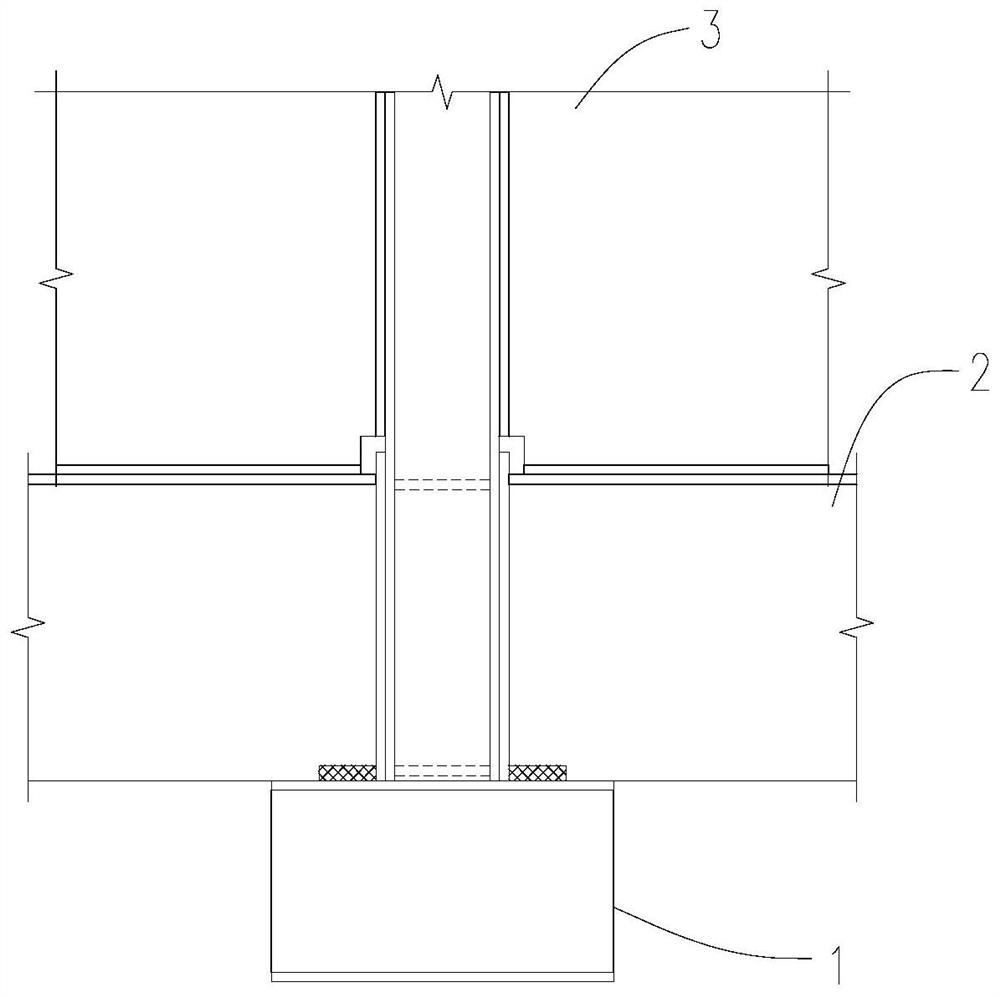

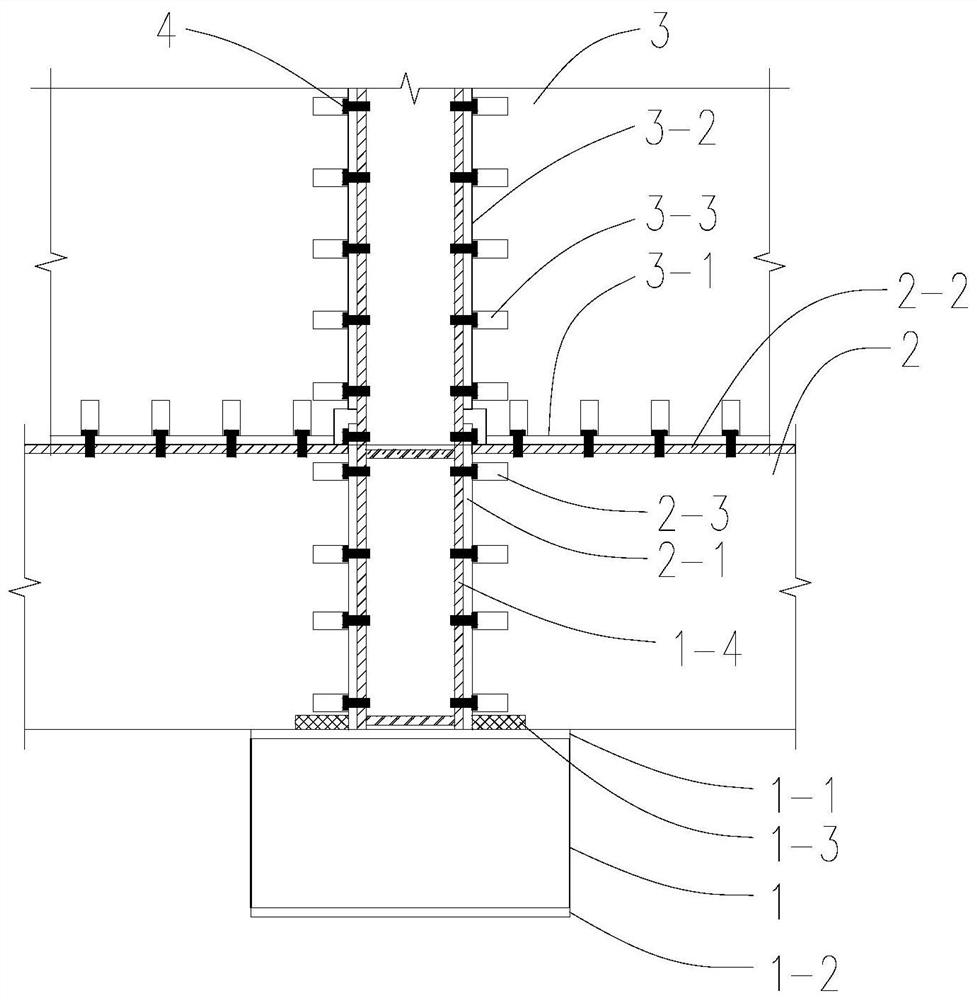

[0030] Such as figure 1 As shown, it is the prefabricated concrete ground beam-shear wall connection node according to the present invention, which includes a conversion column 1 , a ground beam 2 and a shear wall 3 .

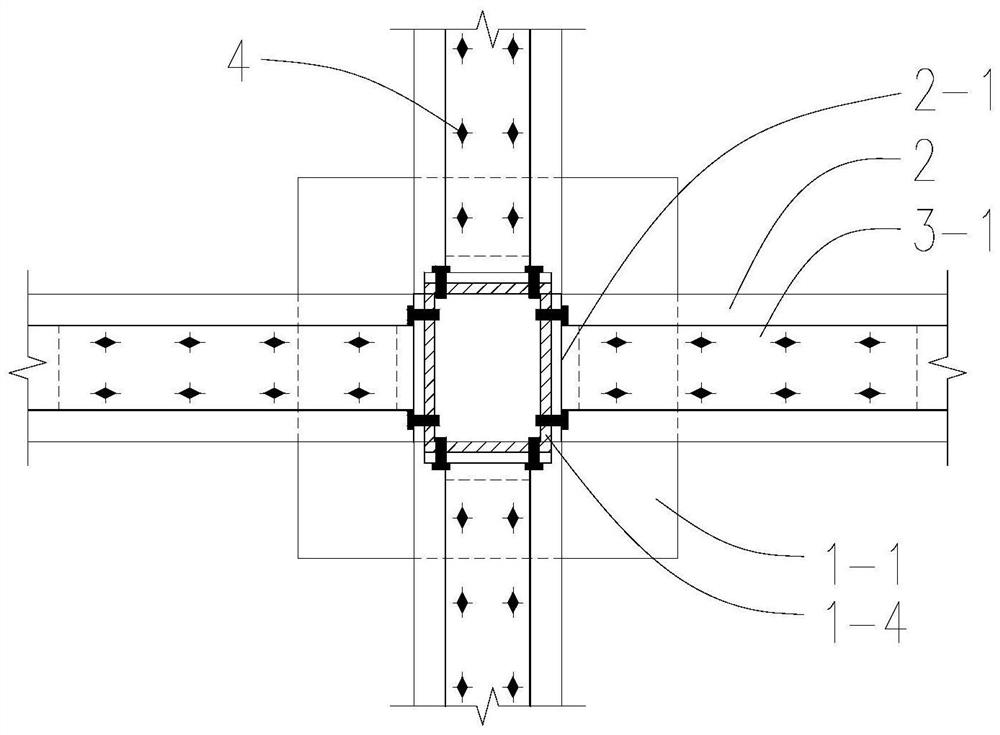

[0031] The bottom and top of the conversion column 1 are pre-embedded with the top steel plate 11 and the bottom steel plate 12 respectively with bolt holes, and the inner longitudinal ribs of the conversion column 1 are welded to the pre-embedded top steel plate 11 and bottom steel plate 12 at the upper and lower ends; the conversion column 1 The upper part is provided with a stem 14, the bottom of the stem 14 is located inside the conversion column 1, and is integrally connected with the conversion column 1. The stem 14 is made of a rectangular steel pipe, and the four walls are provided with bolt holes. The height of the stem is equal to the height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com