Electric heating dipping and drying rotary kiln

An electric heating and rotary kiln technology, applied in lighting and heating equipment, rotary drum furnaces, sustainable manufacturing/processing, etc., can solve the problems of inability to meet catalyst drying requirements, too much liquid on catalyst surface area, and difficulty in catalyst withdrawal. Achieve the effect of avoiding unloading difficulties, avoiding unstable operation and uniform load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

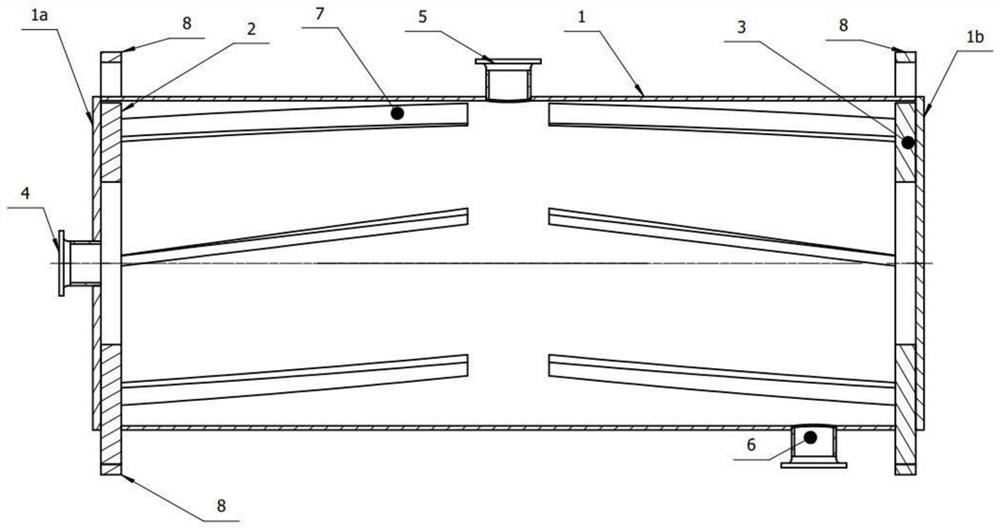

[0056] figure 1 Schematically shows the cross-sectional structure of an electric heating impregnation drying rotary kiln passing through the rotation axis of the rotary tube, such as figure 1 As shown, the rotary tube 1 is a cylinder with two end panels 1a and 1b at both ends, which is made of insulating material. The two ends of the rotary tube 1 are provided with a negative pole 2 and a positive pole 3. The positive and negative poles of the power supply pass through the wall of the rotary tube 1 and are electrically connected to the two conductive rings 8 outside the rotary tube 1. The two conductive rings 8 are further conductively connected to the positive and negative poles of the heating power supply through brushes respectively. A first nozzle 4 is opened on the cover plate of the rotary pipe end, and a second nozzle 5 and a third nozzle 6 are opened on the cylinder wall. A plurality of frying boards 7 are fixed on the inner wall of the rotary tube cylinder 1. When t...

Embodiment 2

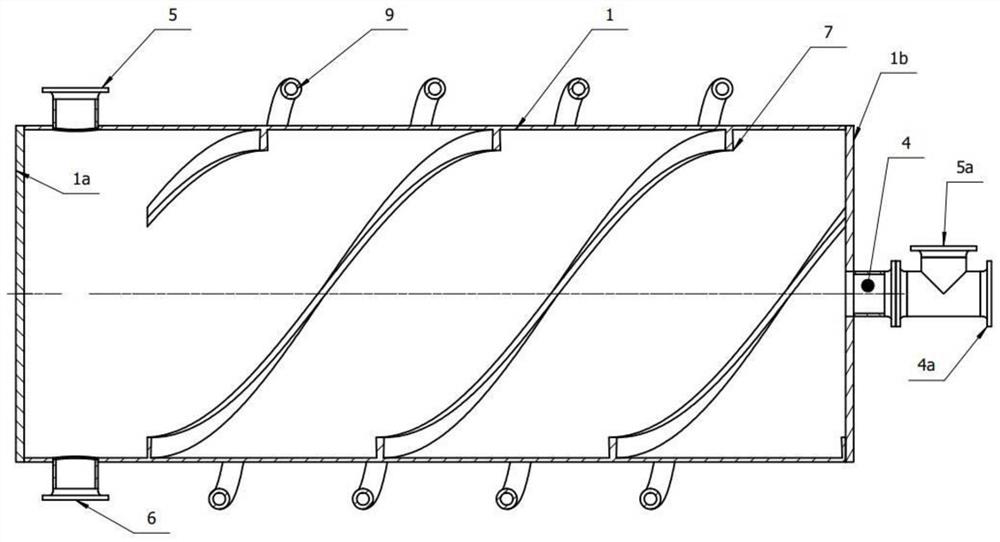

[0062] figure 2 It shows the cross-sectional structure of another electric heating impregnation drying rotary kiln passing through the rotation axis of the rotary tube. Such as figure 2 As shown, the difference from Embodiment 1 is that no electrodes are arranged inside the rotary tube 1 . The cylinder of the rotary tube is covered with an induction coil 9, and the coil is made of a copper tube, and the cylinder of the rotary tube 1 is made of an epoxy resin plate. When heating, a 1 kHz alternating current is applied at both ends of the coil 9, and an induced current is generated in the activated carbon carrier pile inside the rotary tube 1. The carrier pile has a certain resistance, thereby generating resistance heat to heat and dry the catalyst.

[0063] The entry and exit of solid, gas and liquid materials can be carried out in the manner described in Example 1. Since the inclination of the frying plate 7 in the present embodiment along the direction of the axis of rot...

Embodiment 3

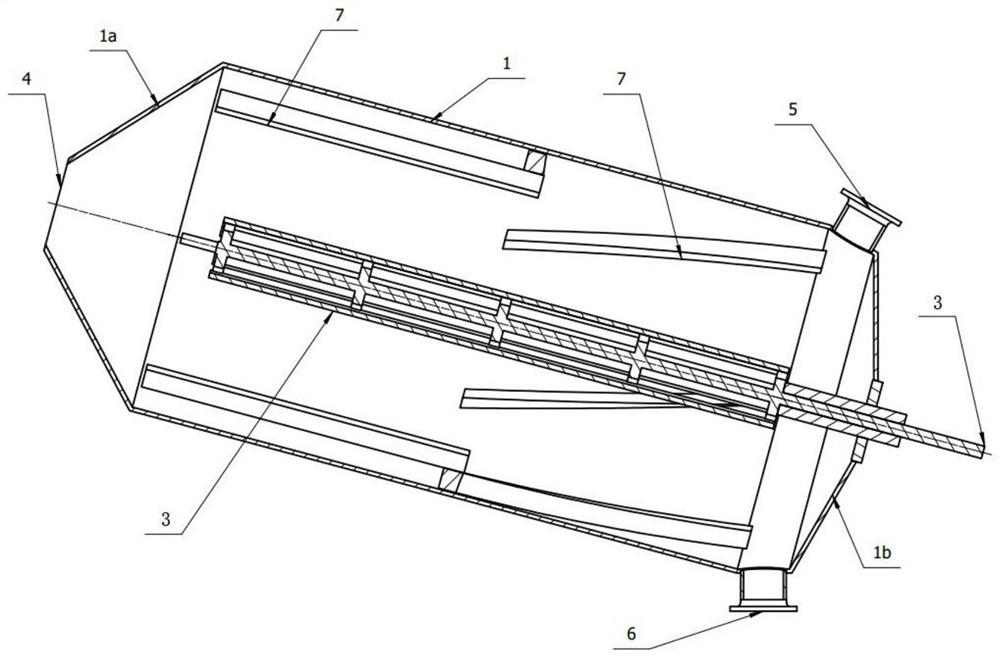

[0067] image 3 It shows the cross-sectional structure of another electric heating impregnation drying rotary kiln passing through the rotary axis of the rotary tube, such as image 3 As shown, the rotary tube 1 is made of metal material, and the included angle between its rotation axis and the horizontal plane is 15°. The positive pole 3 is mechanically sealed but electrically insulated with the rotary tube 1, and the rotary tube 1 is used as the negative pole of the power supply. The first nozzle 4 is used as the inlet of the solid material and the outlet of the gas phase, the third nozzle 6 is used as the outlet of the circulating immersion liquid, and the second nozzle 5 is used as the outlet of the solid material. When the solid material is unloaded, the second nozzle 5 rotates to the third nozzle 6 in the accompanying drawing. Because the inclination of the rotary pipe 1 is relatively large, it is easy to discharge the catalyst with good fluidity such as activated carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com