BIT product continuous channelization cyclization process and reaction equipment thereof

A technology of reaction equipment and pipeline reactor, which is applied in the field of BIT product continuous pipeline cyclization process and its reaction equipment, can solve problems affecting the application of BIT products, achieve high initiation rate, accelerate production speed, and reduce equipment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

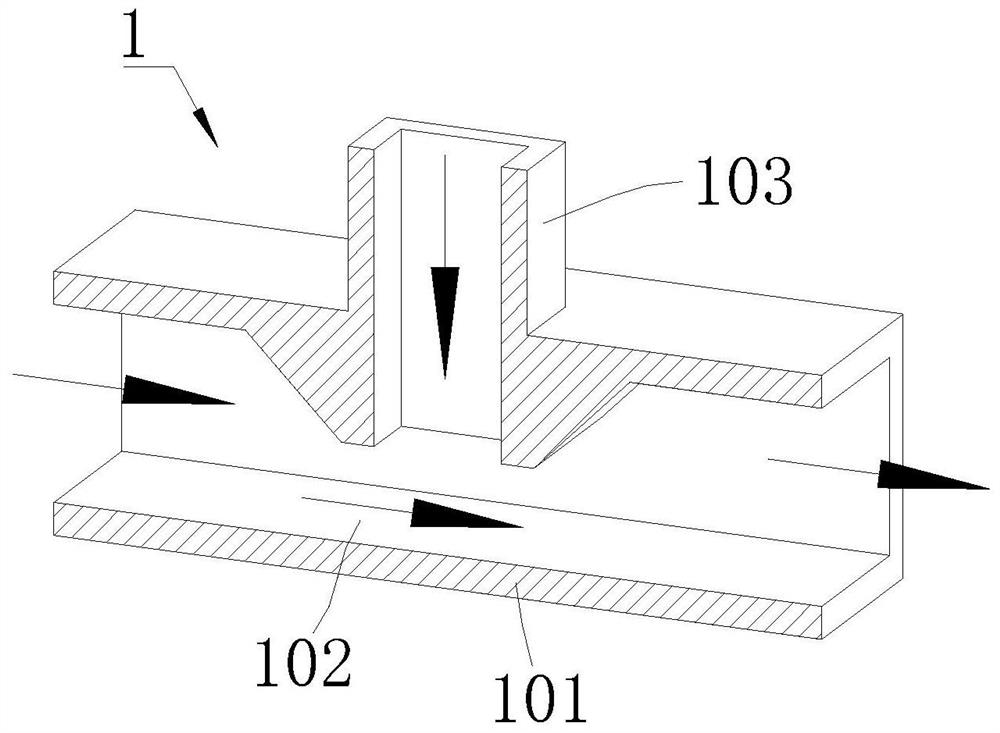

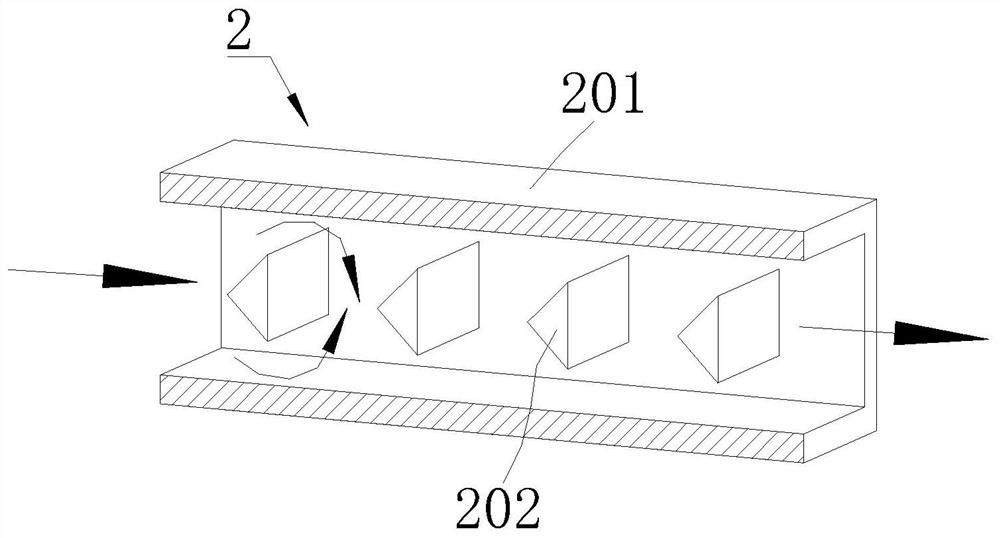

[0057] Specific embodiment one: please refer to Figure 1-16 A reaction device for a continuous piped cyclization process of BIT products, comprising a piped reactor, the piped reactor includes a converging unit 1, a mixing unit 2 and a reaction unit 3 connected in sequence.

[0058] The confluence unit 1 includes a confluence pipe 101 for inputting a liquid reactant A, and the liquid reactant B is sucked into the confluence unit 1 by the suction of the reactant A to form a mixed solution.

[0059] The intersection pipe 101 is provided with a narrow tube area 102, the diameter of which is much smaller than that of other areas, and the upper end of the narrow tube area 102 is connected with a suction pipe 103, which is connected with a liquid storage tank 104 for storing reactant B, and the suction pipe A starting valve is provided in 103 , and when the suction force of the narrow pipe area 102 reaches the starting threshold, the starting valve is opened, and the reactant B flo...

specific Embodiment 2

[0084] Specific embodiment two: on the basis of specific embodiment one, please refer to Figure 17 A kind of reaction equipment of the BIT product continuous pipeline ring closure process, the upper side of the heat preservation pipeline 401 is provided with an air outlet pipe 403, and the air outlet pipe 403 is provided with an air outlet one-way valve 405. The air outlet one-way valve 405 includes an air outlet temperature-sensing blocking sheet 405-1 and an air outlet grille plate 405-2. The air outlet grille plate 405-2 is fixed in the air outlet pipe 403 and communicates with the upper and lower sides. The air outlet temperature-sensing blocking piece 405-1 is made of memory alloy, and the deformation temperature of memory alloy is 50°C. The air outlet temperature sensing blocking sheet 405-1 is placed on the upper side of the air outlet grille plate 405-2. The air outlet temperature-sensing blocking sheet 405-1 is in the form of a cover when the environment is lower t...

specific Embodiment 3

[0085] Specific embodiment three: on the basis of specific embodiment one or two, please refer to Figure 18 A kind of reaction equipment of BIT product continuous pipeline cyclization process, the intersection unit 1 also includes a liquid storage tank 104, and the liquid storage tank 104 stores chlorinated liquid or 30% liquid caustic soda. When ammonia water flows in the narrow tube area 102 , what is stored in the liquid storage tank 104 is chlorinated liquid. When the mixture of ammonia water and chlorinated liquid flows in the narrow tube area 102, what is stored in the liquid storage tank 104 is 30% liquid caustic soda. The suction pipe 103 is a siphon pipe, and a section of the suction pipe 103 is submerged under the liquid level of the liquid storage tank 104 , and the liquid storage tank 104 is higher than the junction pipe 101 . When the liquid in the narrow pipe area 102 flows, the gas in the suction pipe 103 is sucked out until the liquid level at the other end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com