Novel wood chopping board not prone to cracking and chip shedding and production method thereof

A production method and cutting board technology, which is applied in the jointing of wooden veneers, wood processing appliances, household appliances, etc., can solve the problems of sawdust removal and cutting boards that are easy to burst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

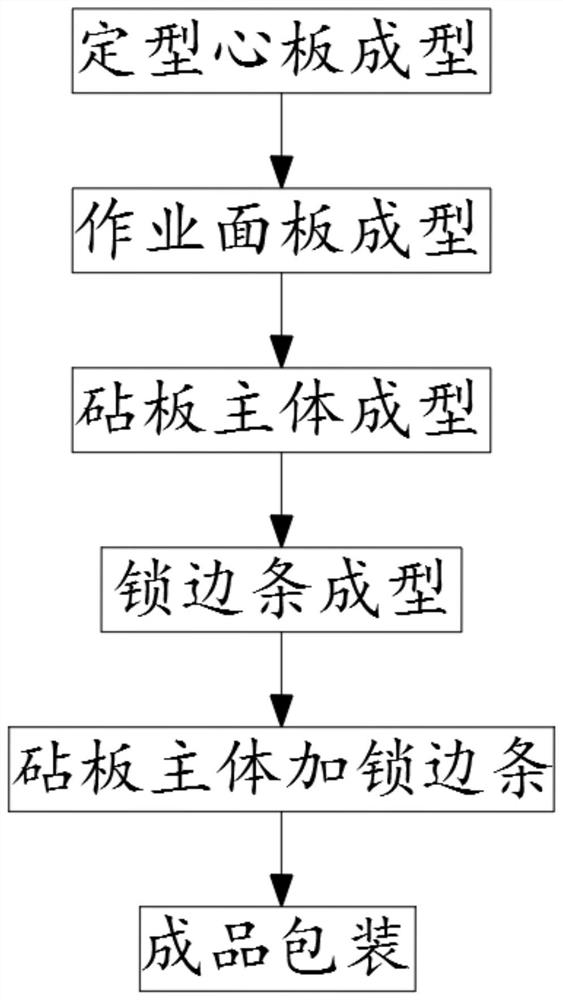

[0038] Such as figure 1 Shown, a kind of production method of the novel wooden chopping board that is not easy to burst and drop sawdust, is characterized in that, comprises the following steps:

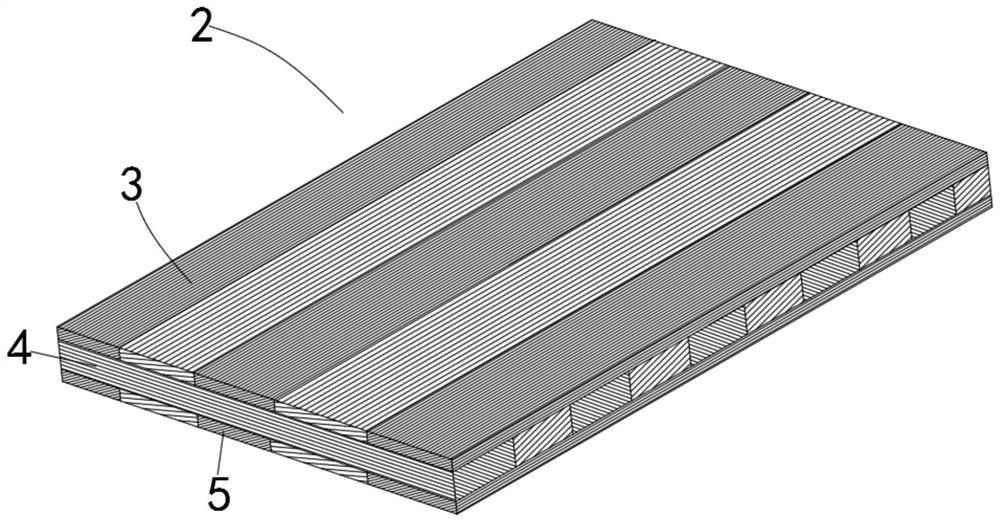

[0039]Step 1): The formation of the shaped core board 2 is processed into a plurality of planks by using ordinary planks or leftover materials, bonding the plurality of planks with an environmentally friendly adhesive and pressing them tightly, and making the plurality of planks into a balanced shape respectively The core plate 3, the central plate 4, and the lower balanced shaped core plate 5, and then the balanced shaped core plate 3, the central plate 4, and the lower balanced shaped core plate 5 are bonded with non-toxic, harmless and environmentally friendly wood special splicing glue and applied high pressure Auxiliary force to bond and compress the three to form a shaped core plate 2;

[0040] Step 2): For the formation of the operation panel, select wood strips with differen...

Embodiment 2

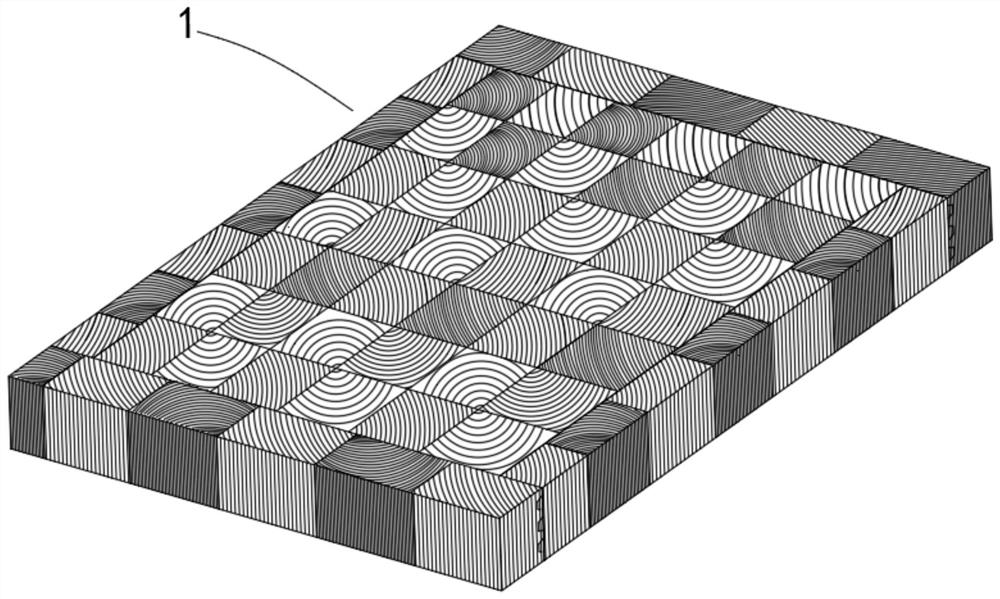

[0052] Such as Figure 2-8 As shown, a specific new wooden cutting board that is not easy to burst and lose wood chips includes a cutting board main body 1, and the shape of the cutting board main body 1 is any one of rectangle, square or circle. The cutting board main body 1 of this embodiment is rectangular The main body of the chopping board 1 is surrounded by horizontal seaming strips 8 and longitudinal seaming strips 9, the main body of the cutting board 1 is fixed with the horizontal seaming strips 8 and the longitudinal seaming strips 9 through a mortise and tenon structure, and the cutting board main body 1 is laminated by multiple layers , the cutting board main body 1 has a shaped core board 2, the fibers of the shaped core board 2 are staggered at 90°, the cutting board main body 1 has at least one layer of operation panels, the operation panels intersect and perpendicular to the fibers of the shaping core board 2, and the fibers of the operation panel The trending ...

Embodiment 3

[0054] Such as Figure 4 Or as shown in 6, the anvil block main body 1 has at least four layers of pressing, and it is sequentially pressed from top to bottom with an upper operation panel 7, a shaped core plate 2 and a lower operation panel 6, and the shaped core plate 2 is pressed together from the top to the bottom. There are an upper balance shaped core plate 3, a center plate 4 and a lower balanced shaped core plate 5 pressed together downwards sequentially.

[0055] Such as image 3 As shown, the fiber direction of the upper balance shaping core plate 3, the lower balance shaping core plate 5 and the center plate 4 is staggered at 90°, the lower operation panel 6, the upper operation panel 7 and the horizontal seam The fibers of bar 8 and longitudinal overlock bar 9 move towards the same direction.

[0056] The upper balance shaping core plate 3, the center plate 4 and the lower balance shaping core plate 5 of the shaping core plate 2 are rectangular plates, and the fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap