Greening method for revetment of city moat

A moat and revetment technology, applied in the field of revetment ecological greening, can solve the supply obstacles of aquatic plants, lack of living space and environment for plants, soil animals and microorganisms, ignore the structure and function of river ecosystems, restore river bank vegetation and wetland communities and other problems to achieve the effect of promoting root growth and accelerating metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

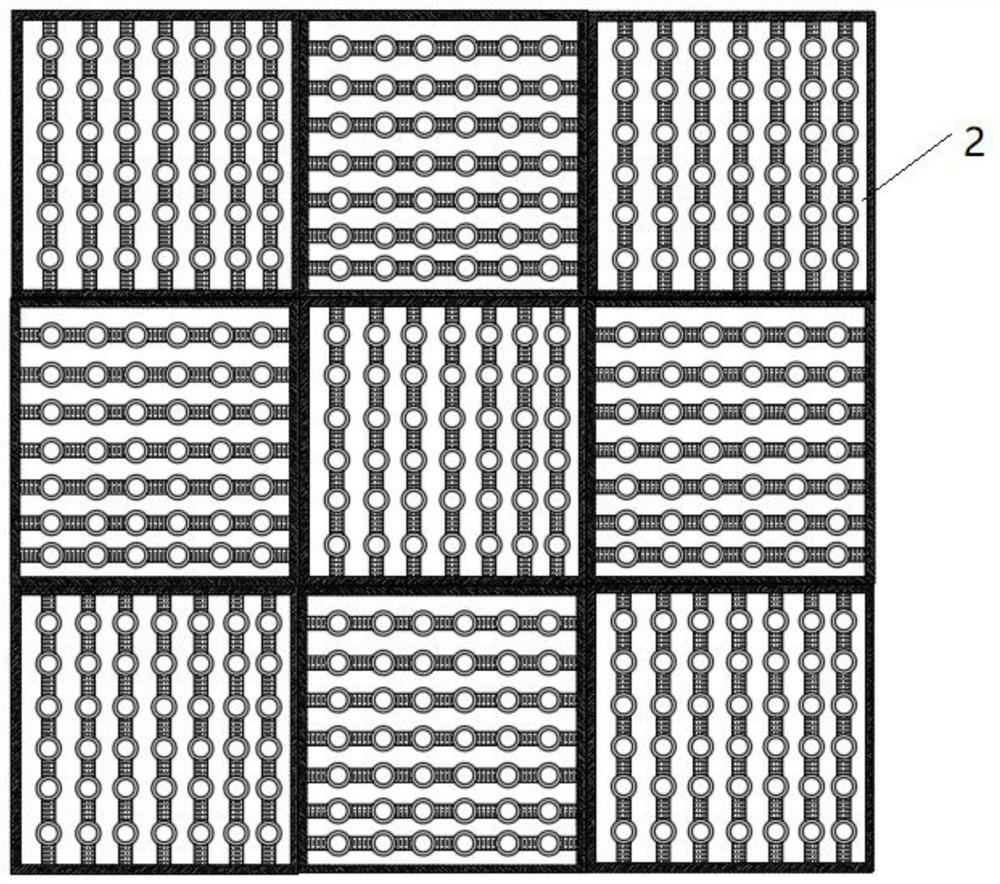

[0047] Experimental location: the east section of the Huancheng River in the old city of Fuyang, with a revetment length of 3.8km;

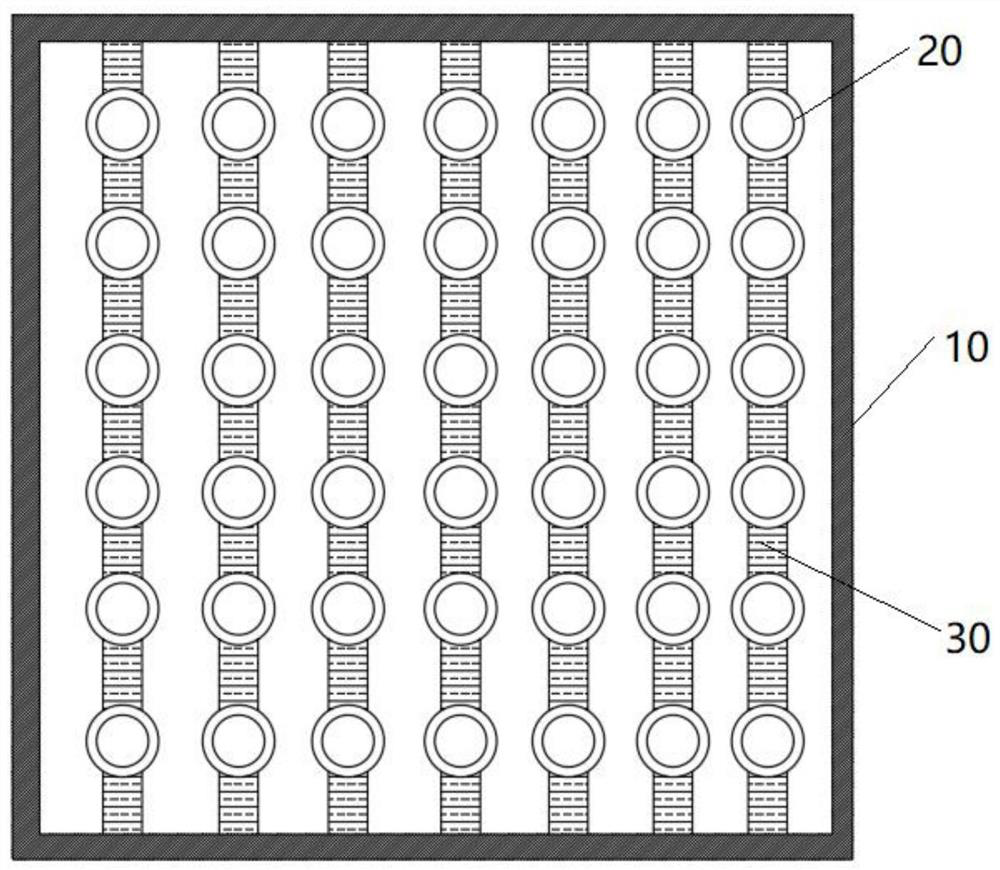

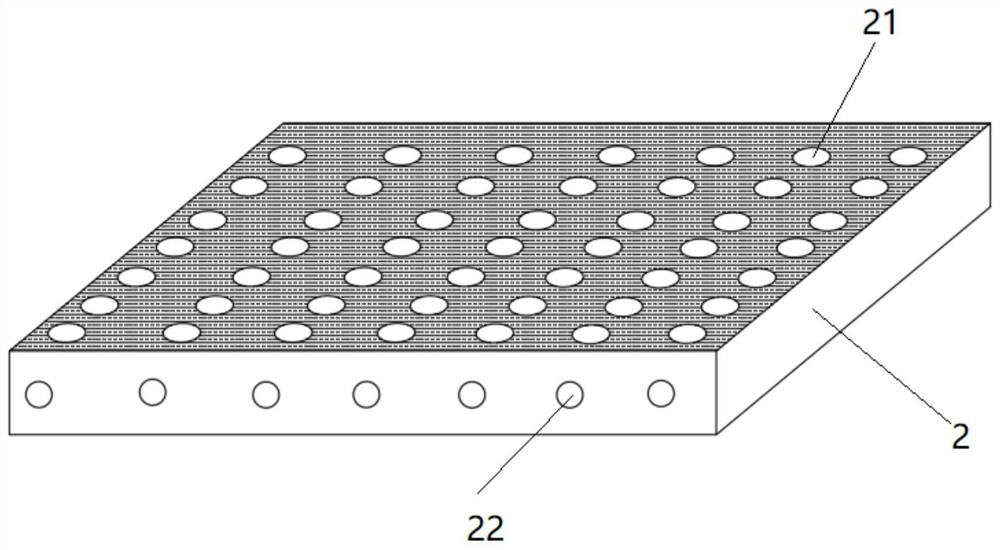

[0048] S1. Select a square plank with a side length of 80cm, and nail four side planks with a length of 80cm and a width of 20cm along the vertical direction of the plank to make a wooden groove with a depth of 20cm, and place them evenly in the wooden groove. Place 7×7 hollow moso bamboo tubes with both ends through, and open two symmetrical through holes in the middle of the hollow moso bamboo tube, and insert a thin bamboo pole through the middle along the longitudinal direction into the hole opened in the middle of the hollow moso bamboo tube. In the hole, the hollow moso bamboo tubes arranged vertically are pierced into a whole, and the two ends of the thin bamboo poles and the side wooden boards are tightly fixed to each other to make a slope protection board mold;

[0049] S2. Inject the concrete slurry into the above-mentioned slope prote...

example 2

[0057] Experimental location: the west section of the Huancheng River in the old city of Fuyang, with a revetment length of 4.4km;

[0058] S1. Select a square plank with a side length of 80cm, and nail four side planks with a length of 80cm and a width of 20cm along the vertical direction of the plank to make a wooden groove with a depth of 20cm, and place them evenly in the wooden groove. Place 7×7 hollow moso bamboo tubes with both ends through, and open two symmetrical through holes in the middle of the hollow moso bamboo tube, and insert a thin bamboo pole through the middle along the longitudinal direction into the hole opened in the middle of the hollow moso bamboo tube. In the hole, the hollow moso bamboo tubes arranged vertically are pierced into a whole, and the two ends of the thin bamboo poles and the side wooden boards are tightly fixed to each other to make a slope protection board mold;

[0059]S2. Inject the concrete slurry into the above-mentioned slope protec...

example 3

[0067] Experimental location: the southern section of the Fuyang old city ring city, with a revetment length of 2.6km;

[0068] S1. Select a square plank with a side length of 80cm, and nail four side planks with a length of 80cm and a width of 20cm along the vertical direction of the plank to make a wooden groove with a depth of 20cm, and place them evenly in the wooden groove. Place 7×7 hollow moso bamboo tubes with both ends through, and open two symmetrical through holes in the middle of the hollow moso bamboo tube, and insert a thin bamboo pole through the middle along the longitudinal direction into the hole opened in the middle of the hollow moso bamboo tube. In the hole, the hollow moso bamboo tubes arranged vertically are pierced into a whole, and the two ends of the thin bamboo poles and the side wooden boards are tightly fixed to each other to make a slope protection board mold;

[0069] S2. Inject the concrete slurry into the above-mentioned slope protection plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com