Waste heat recovery stainless steel heat exchanger based on flue gas turbulence technology

A waste heat recovery and heat exchanger technology, applied in heat exchange equipment, heat exchangers, indirect heat exchangers, etc., can solve the problems of poor heat exchange effect and low heat exchange efficiency of heat exchangers, and achieve full recovery, Promotes a uniform and efficient, turbulent flow-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

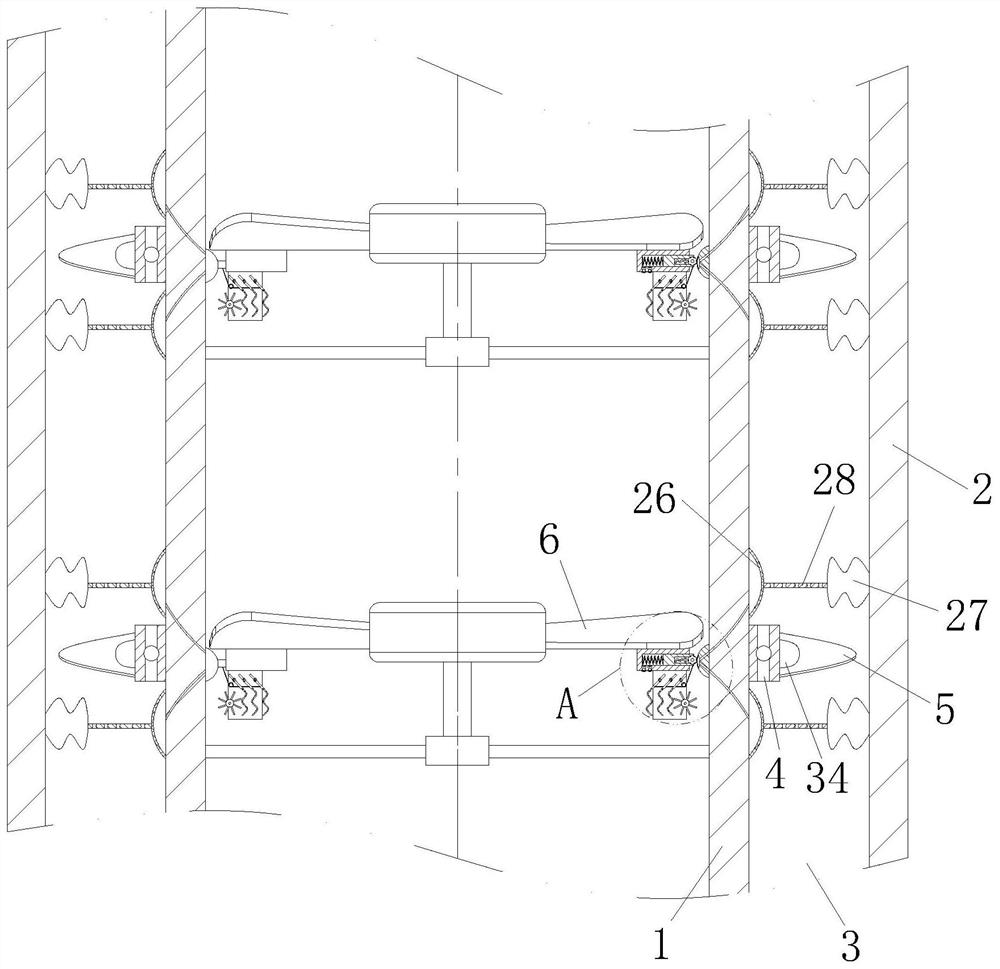

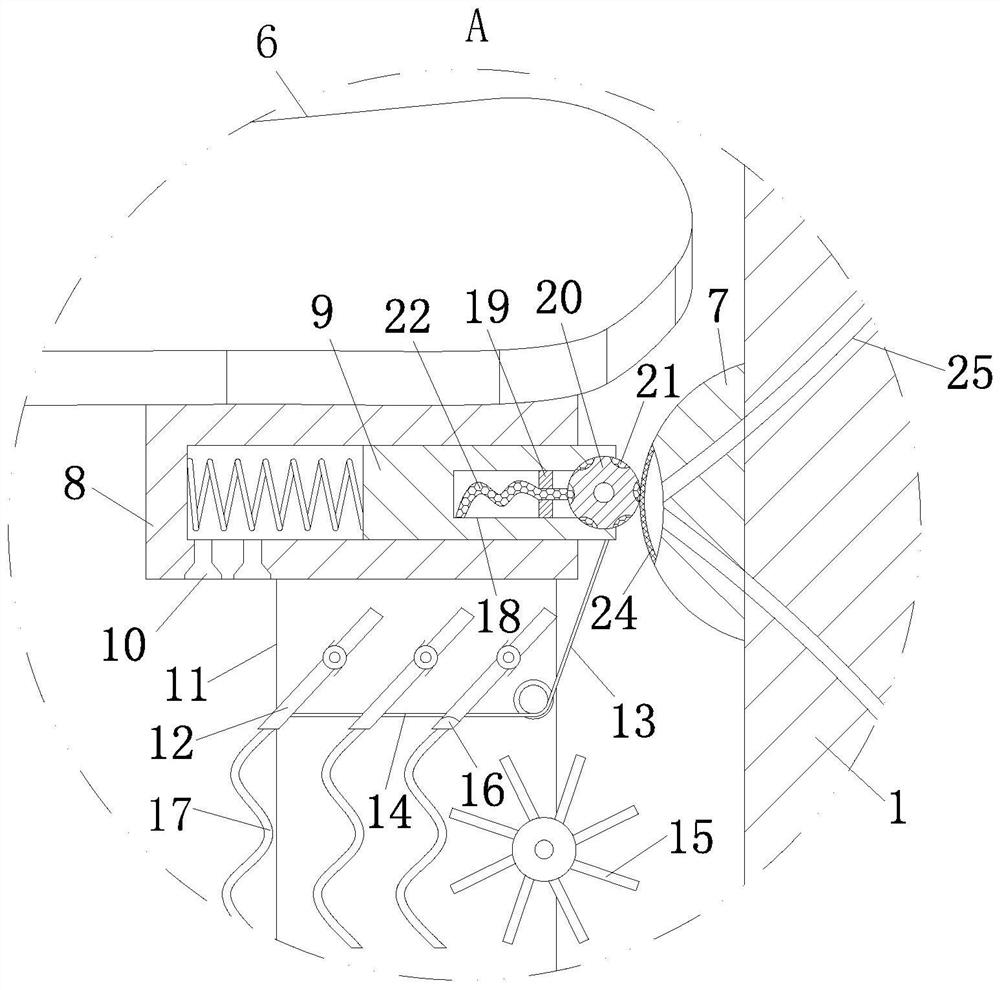

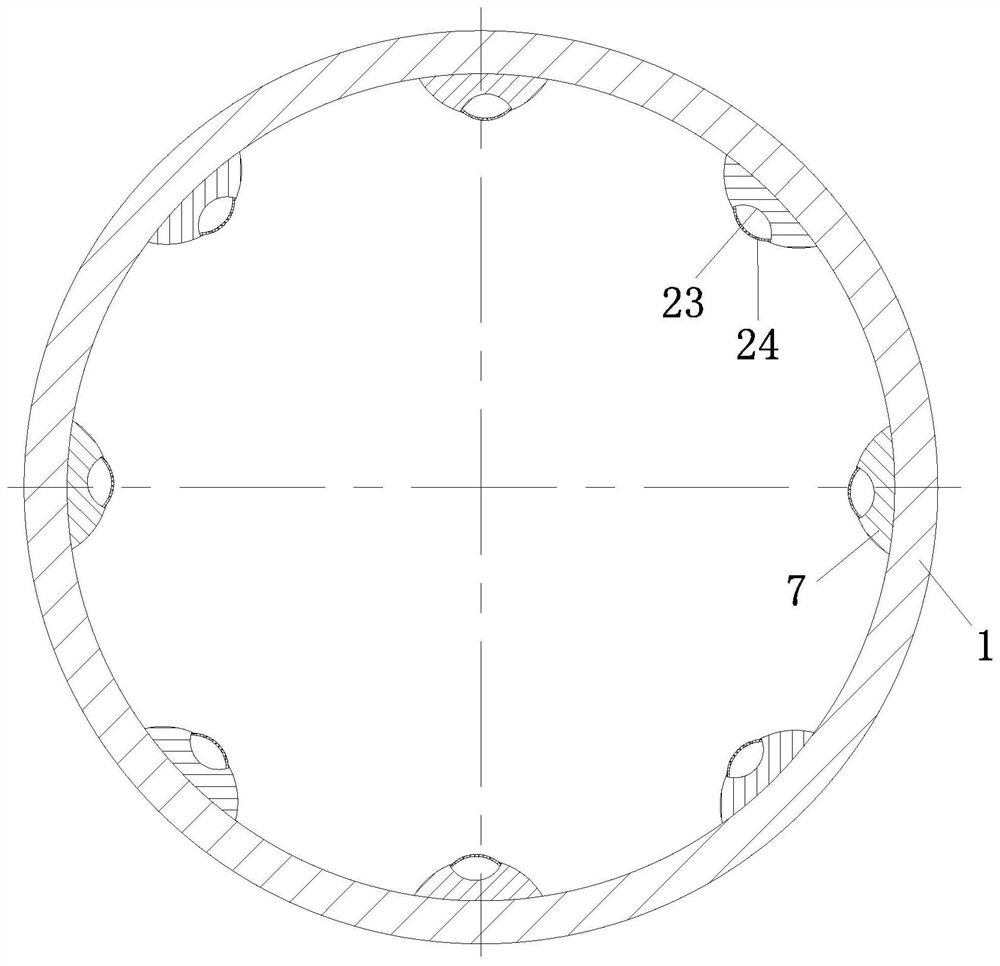

[0027] see Figure 1-3As shown, a waste heat recovery stainless steel heat exchanger based on flue gas turbulence technology according to the present invention includes a heat exchange tube 1 made of stainless steel; A water flow channel 3 is formed between the pipe 1 and the water pipe 2. A set of rotary sleeves 4 is connected to the outer wall of the heat exchange tube 1 along its axial direction. The rotary sleeve 4 is connected with a spiral blade 5. The heat exchange tube 1 The fan blade 6 is rotatably connected to the position corresponding to the rotating sleeve 4 inside, and the magnetic layer 34 capable of attracting the fan blade 6 is inlaid on the spiral blade 5; the waste heat recovery stainless steel heat exchanger in the prior art is used When the hot gas or water flow is in a laminar flow state during the smooth flow process, the heat exchange effect of the heat exchanger is not good; while the waste heat recovery stainless steel heat exchanger in the present in...

Embodiment 2

[0036] see Figure 4 As shown, the outer end of the side wall of the oil storage chamber 18 corresponding to the two sides of the roller 20 is provided with an escape chamber 29, and the outer end of the lubricating body 21 is provided with an arc-shaped portion 30 protruding to the outside of the oil storage chamber 18; When the roller 20 drives the arc-shaped part 30 adsorbed with lubricating oil to move to the surface of the bump 7, the roller 20 and the bump 7 can squeeze the arc-shaped part 30 and make the lubricating oil inside it fully outflow, so as to play a more effective lubricating effect on the surface of the bump 7 .

[0037] The avoidance cavity 29 is connected with a sealing film 31 that is attached to the side wall of the roller 20, a magnetic body 32 is installed inside the lubricating groove, and a magnetic body 32 is attached on the inner wall of the sealing film 31 that can repel the magnetic body 32. The flexible magnetic strip 33; when the roller 20 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com