Quantitative evaluation method for precipitation velocity of hypereutectoid steel network cementite

A technology of hypereutectoid steel and quantitative evaluation, which is applied in the direction of material analysis, measuring device, and material analysis by optical means, which can solve the problems such as the change of the precipitation speed of the reticulated cementite of the wire rod, etc., to prevent cooling. The effect of excessive speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] 1) Preparation of thermal simulation samples: Hypereutectoid steel is smelted in a 200kg vacuum furnace, and then the steel ingot is heated to 1050°C-1100°C, kept for 30min-40min, rolled into a 20mm-30mm thick steel plate, and wire-cut The method is prepared on the steel plate thermal simulation samples.

[0026] 2) Heat the thermal simulation sample to a temperature of 850°C-950°C and keep it warm for 8min-15min. Cool the sample to the set temperature at a cooling rate of 0.1°C / s-5°C / s, and then cool it to room temperature at a cooling rate of 20°C / s-25°C / s;

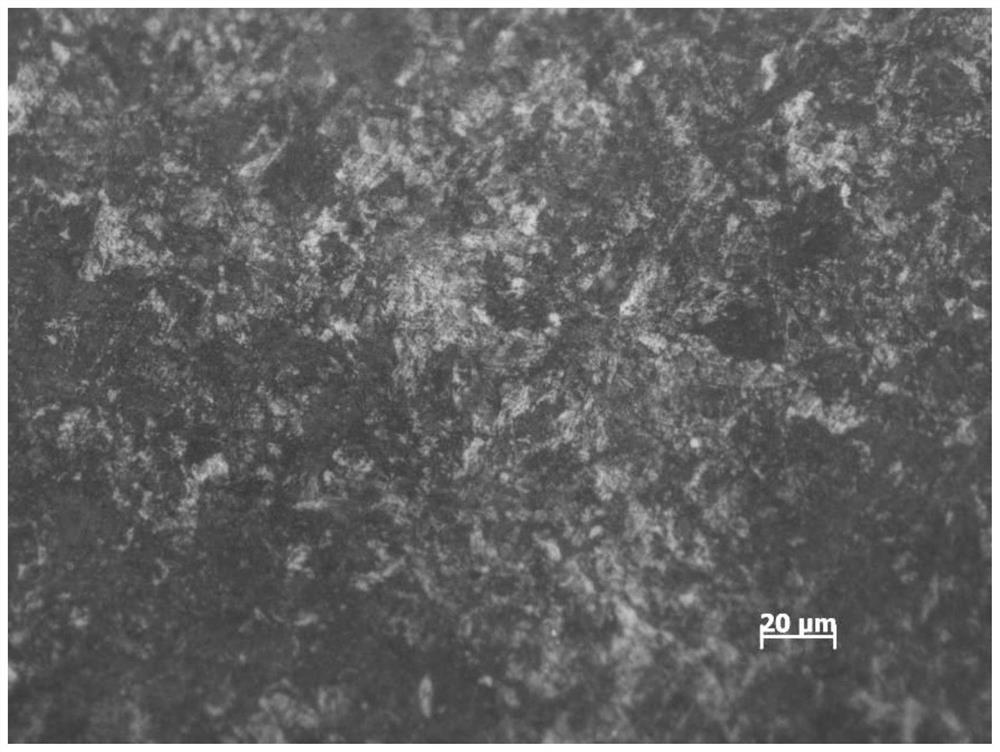

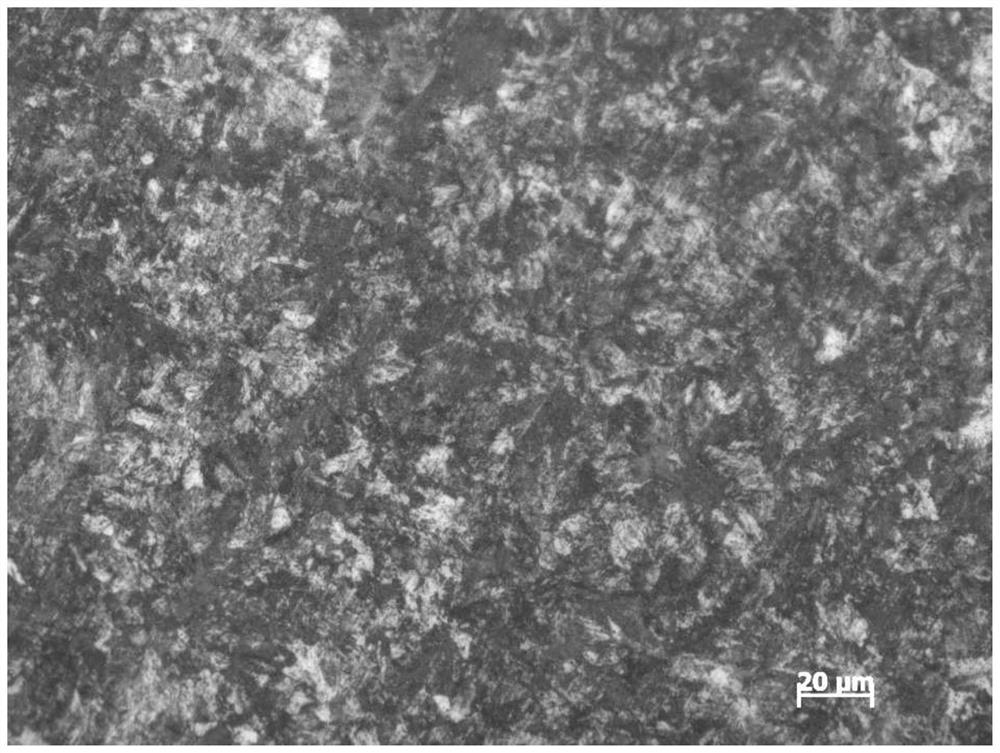

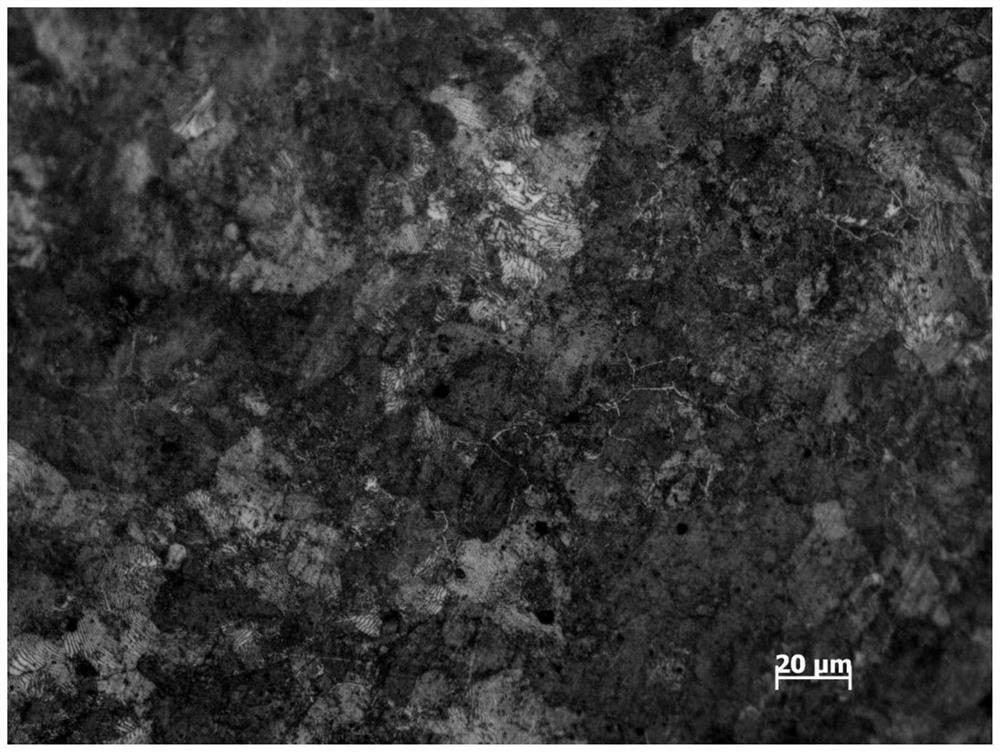

[0027] 3) After the sample is inlaid, ground, and polished, it is corroded with 5% nitric acid alcohol solution; the corroded metallographic sample is observed with an optical microscope: the sample is initially observed at a magnification of 200-1000 times, Determine the area where the network cementite precipitation is the most serious, as the field of view for the evaluation of the sample network cementite;...

Embodiment

[0034] The chemical composition of the sample is calculated by weight percentage as C 0.96%; Si 0.22%; Mn 0.65%; Cr 0.15%; the rest is Fe and unavoidable impurities. The sample size is

[0035] Heat the hypereutectoid steel sample with the above chemical composition to 900°C at a rate of 10°C / s, and keep it for 10 minutes to make it fully austenitized.

[0036] After the samples were austenitized, the four samples were cooled to 850°C, 750°C, 650°C, and 550°C, respectively, at a cooling rate of 0.5°C / s. After the sample is cooled to the set temperature, it is then cooled to room temperature at a cooling rate of 20°C / s.

[0037] After mounting, grinding and polishing the sample, it was corroded with 5% nitric acid alcohol solution. The corroded metallographic samples were observed with an optical microscope. Preliminarily observe the sample at a magnification of 500 times to determine the area where the precipitation of reticulated cementite is the most serious, as the fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com