Composite material finished product hole quality detection device

A composite material and detection device technology, applied in measurement devices, analytical materials, material analysis by optical means, etc., can solve the problems of low detection sensitivity, difficult to apply on a large scale, and expensive equipment, to improve detection efficiency, delicate Good balance and fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further described below in conjunction with embodiment and accompanying drawing.

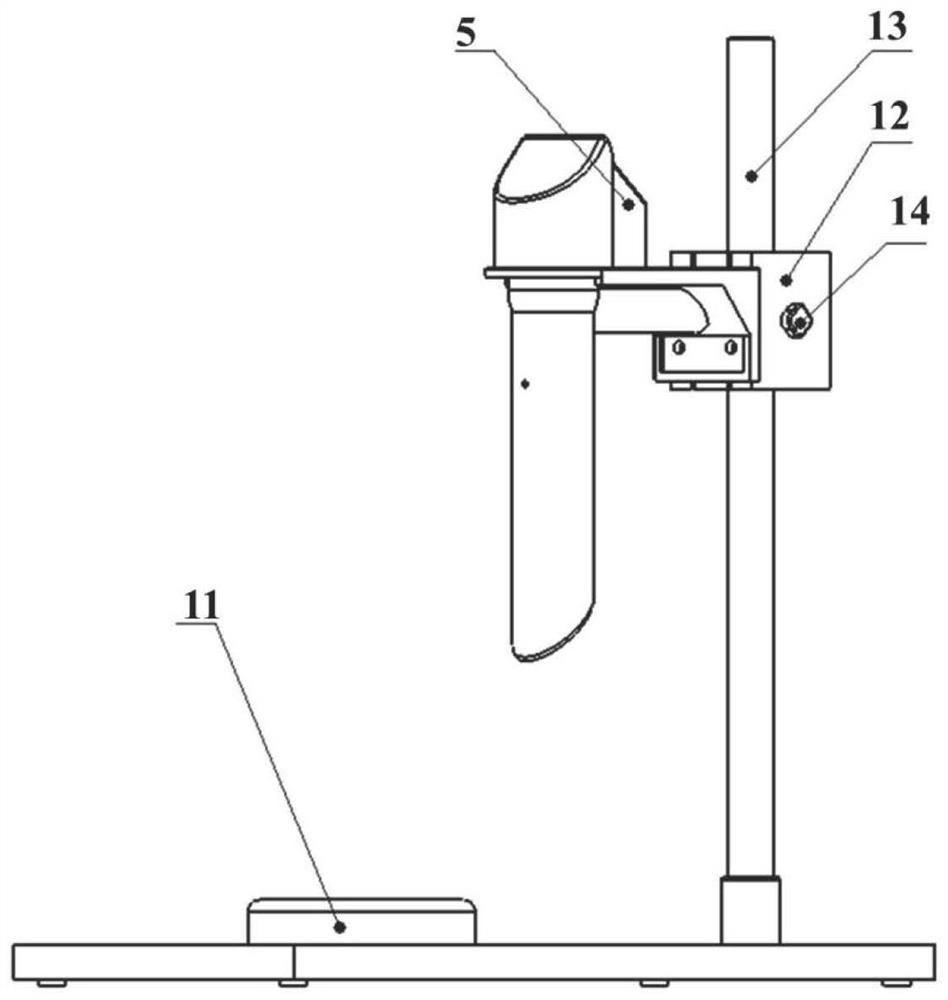

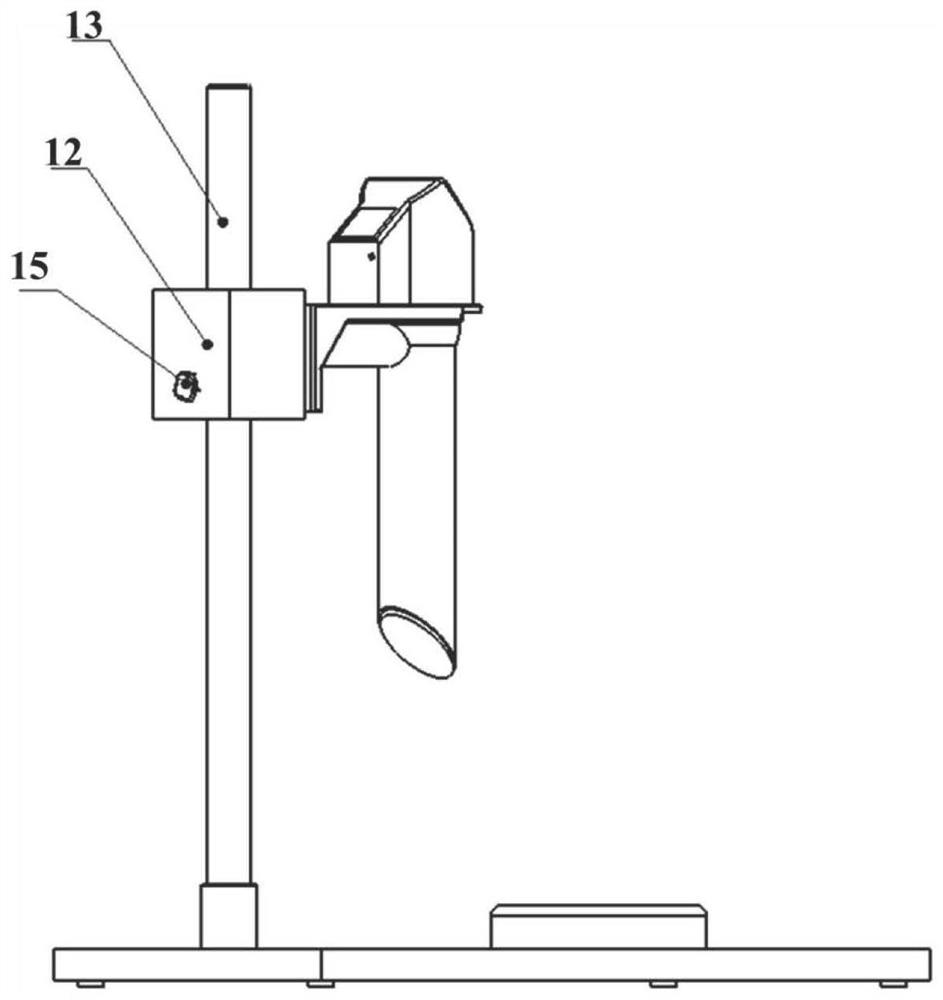

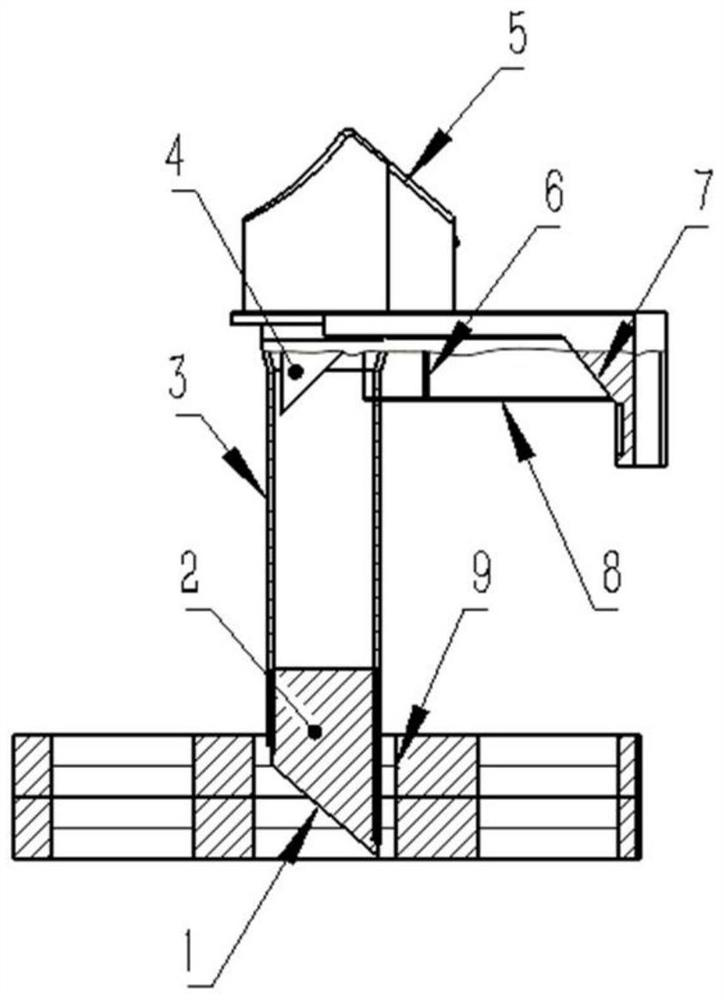

[0035] Such as Figure 1 to Figure 5 As shown, a detection device for the hole quality of a composite material finished product of the present invention includes a detection system and a workbench, the workbench includes a base 10, a test bench 11 and a pole 13 are installed on the base 10, and the detection system includes a lens sleeve 3 , a lens imaging system is installed above the lens sleeve 3, a lamp tube 8 is installed on one side of the lens sleeve 3, a light source 7 and a diffuser plate 6 are arranged in the lamp tube 8, the light source 7 includes an LED lamp group, and the diffuser plate 6 Installed directly in front of the output end of the LED lamp group, the diffuser plate 6 makes the illumination more uniform, the inner bottom of the lens sleeve 3 is provided with a light guide rod 2, and the position corresponding to the lamp tube 8 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com