Low-viscosity refrigerating machine oil base oil, preparation method and application thereof

A technology of refrigeration oil and low viscosity, applied in mixing methods, chemical instruments and methods, base materials, etc., can solve the problems of high base oil cost and easy to cause pollution, and achieve lower production costs, low flocculation point, and significant benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

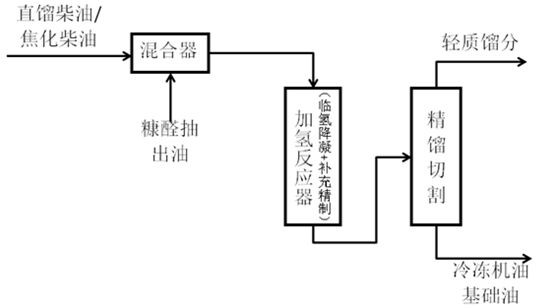

Method used

Image

Examples

Embodiment 1

[0031] After stirring and mixing evenly, naphthenic straight-run diesel oil and coker diesel oil with a mass ratio of 1:1 are used as raw material oil, heated to 280°C, filtered through a filter, and then entered into a hydrogenation reaction device for hydrogenation reaction at a pressure of 15.0MPa. The first-stage reactor is filled with hydrodecondensation catalyst FDW-3 (ZSM-5 zeolite catalyst), the reaction temperature is 280°C, and the volume space velocity is 1.0 h -1 , the second-stage reactor is filled with supplementary refined catalyst RN-1 (nickel-tungsten type), the reaction temperature is 280°C, and the volume space velocity is 1.0 h -1 , The oil after the hydrogenation reaction is rectified and cut, and the light fraction before 260°C is cut off to obtain a low-viscosity refrigerating machine oil base oil.

Embodiment 2

[0033] Use naphthenic straight-run diesel oil, coker diesel oil and furfural extract oil with a mass ratio of 45:45:10 after stirring and mixing uniformly as raw material oil, heat it to 300°C and filter it through a filter, then enter the hydrogenation reaction device, at a pressure of 15.0MPa The hydrogenation reaction is carried out under the following conditions: the first stage of the reactor is filled with the hydrogen depreciation catalyst FDW-3 (ZSM-5 zeolite catalyst), the reaction temperature is 300 °C, and the volume space velocity is 1.0 h -1 , the second-stage reactor is filled with supplementary refined catalyst RN-1 (nickel-tungsten type), the reaction temperature is 300°C, and the volume space velocity is 1.0 h -1 ; After the hydrogenation reaction, the oil product is rectified and cut, and the light fraction before 260°C is cut off to obtain a low-viscosity refrigerating machine oil base oil.

Embodiment 3

[0035] The raw material oil is naphthenic straight-run diesel oil, coker diesel oil and furfural oil with a mass ratio of 35:35:30 after stirring and mixing evenly. The hydrogenation reaction is carried out under the pressure of MPa, and the first-stage reactor is filled with the hydrogen depreciation catalyst FDW-3 (ZSM-5 zeolite catalyst), the reaction temperature is 340°C, and the volume space velocity is 1.0 h -1 The second-stage reactor is filled with supplementary refined catalyst RN-1 (nickel-tungsten type), the reaction temperature is 340°C, and the volume space velocity is 1.0 h -1 ; After the hydrogenation reaction, the oil product is rectified and cut, and the light fraction before 260°C is cut off to obtain a low-viscosity refrigerating machine oil base oil.

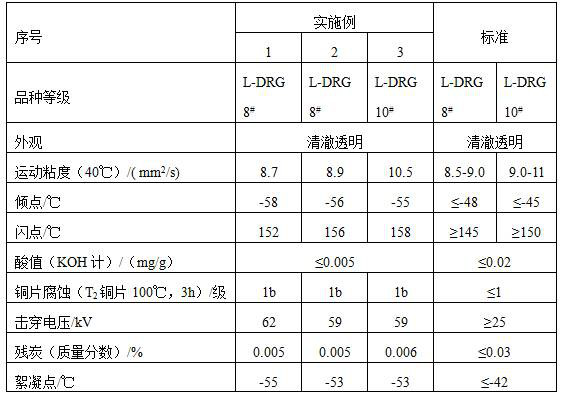

[0036] The data of the products obtained in the above-mentioned Examples 1-3 (the yield is relative to the raw material oil), the standard is the standard index requirement of GB / T 16630-2012 "Refrigeration M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com