Resin removing device and removing method thereof

A technology for removing device and resin, which is applied in the field of resin, can solve the problems of insufficient intelligence, etc., and achieve the effect of easy separation and intelligent cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] In photocuring printing, the 3D data model is first sliced to obtain multiple slice layers, and then the light source projects light on the photosensitive resin according to the shape and thickness of the slice layer, so that the photosensitive resin is cured into the entity corresponding to the slice layer Cured layer, the cured layer is directly formed on the printing platform, and after layer-by-layer stacking, a three-dimensional solid model is finally obtained. But obviously, excess resin will adhere to the surface of the printed 3D solid model, and the excess resin needs to be removed.

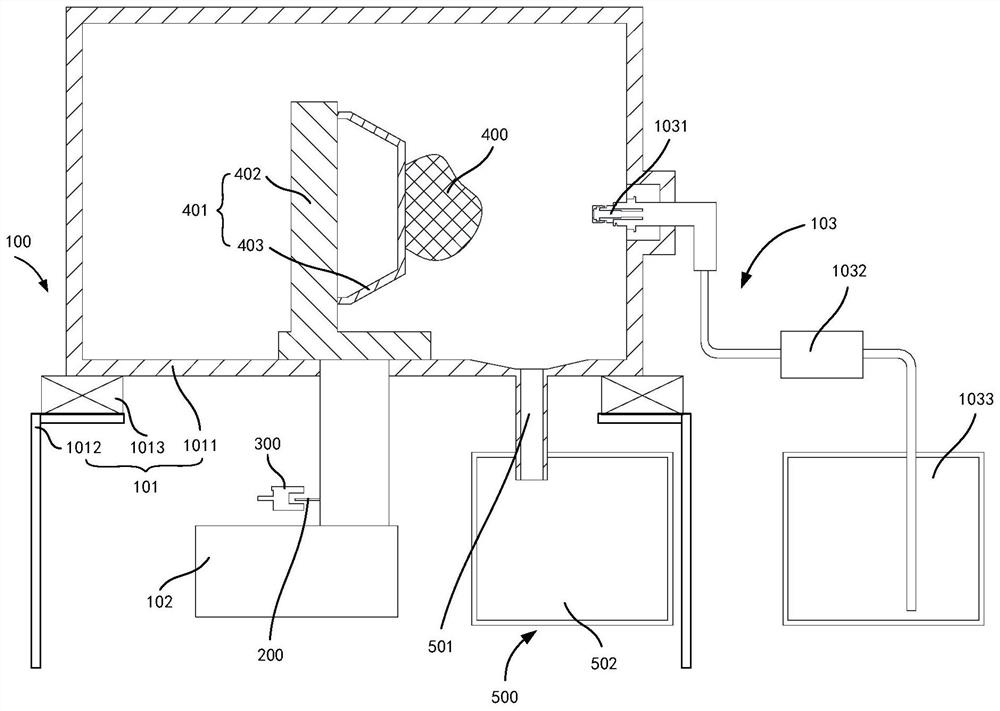

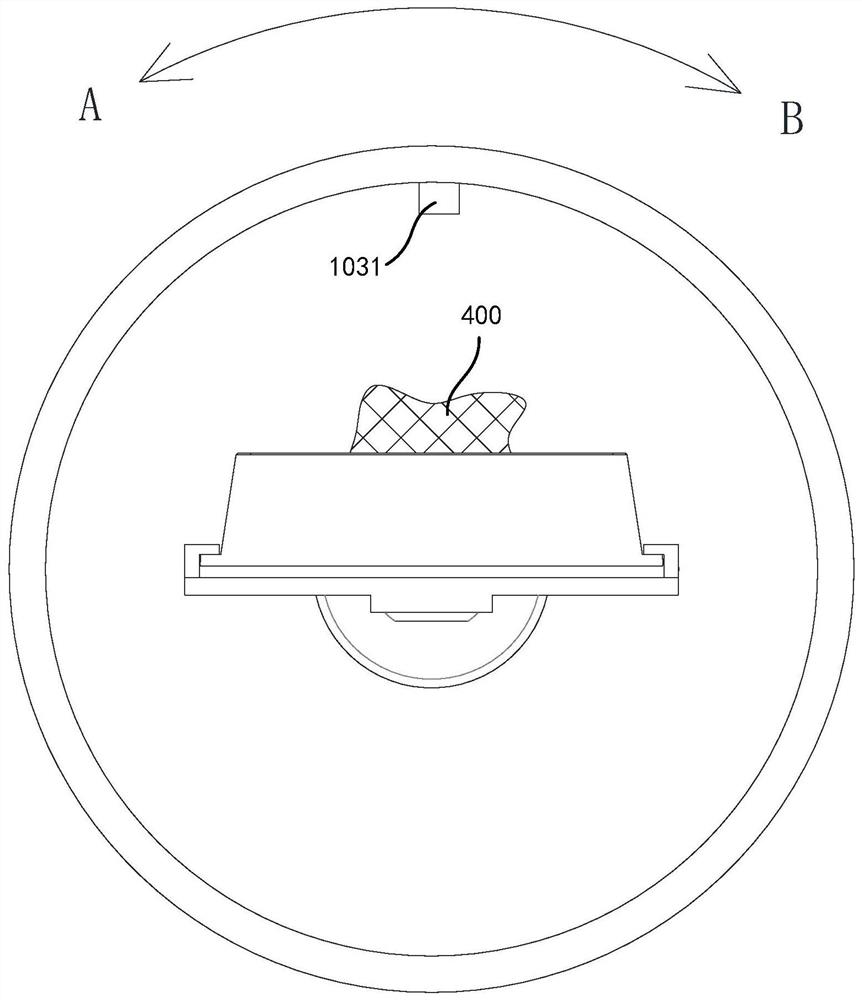

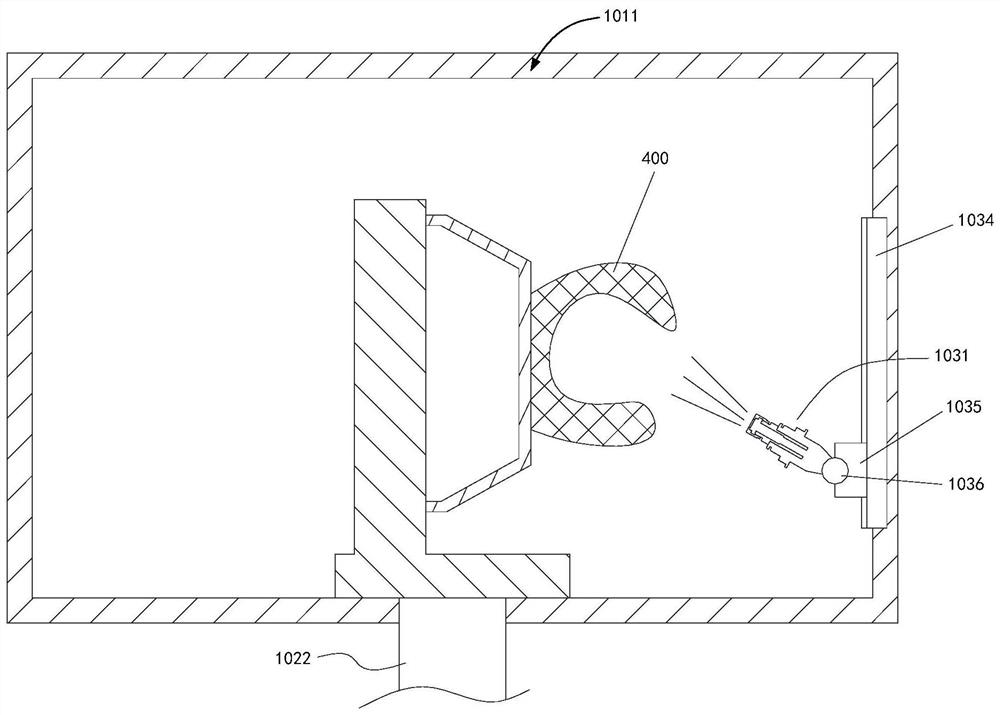

[0046] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a resin removal device and its removal method disclosed in the embodiment of the application; the application provides a resin removal device for removing excess resin on the surface of a three-dimensional solid model (ie, the part to be removed 400 ) printed by a printer Clearing, which include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com