PET plastic plate cleaning agent and preparation method and use method thereof

A technology of cleaning agent and plastic plate, which is applied in the direction of cleaning method and utensils, preparation of detergent mixture composition, cleaning method using liquid, etc., can solve problems such as environmental pollution, deterioration of ground water body, surface discoloration, etc., and reach waste water Easy, low COD production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A cleaning agent for PET plastic plates, consisting of the following components in percentage by weight:

[0053] Narrow molecular weight distribution Gubert alcohol polyoxyethylene ether (5EO) 4.6%;

[0055] Citric acid 4.5%;

[0056] Isooctanoic acid 2.2%;

[0057] Oxalic acid 2.3%;

[0058] Lauryl dimethyl ammonium chloride 2.3%;

[0059] Alcohols 3.5%;

[0060] Deionized water balance.

[0061] Among them, alcohols are composed of 98% isohexanediol and 2% butanol. Citric acid is citric acid monohydrate.

[0062] The preparation method of above-mentioned PET plastic plate cleaning agent is as follows:

[0063] Step A: Add potassium hydroxide, citric acid, oxalic acid and isooctanoic acid to the deionized water in sequence according to the weight percentage, adjust the reaction temperature to 40-50°C, adjust the pH value to 8.0-8.5, stir and mix, and the stirring time 30 minutes, stirring speed is 100 ~ 200rpm.

[0064] Step B...

Embodiment 2-6

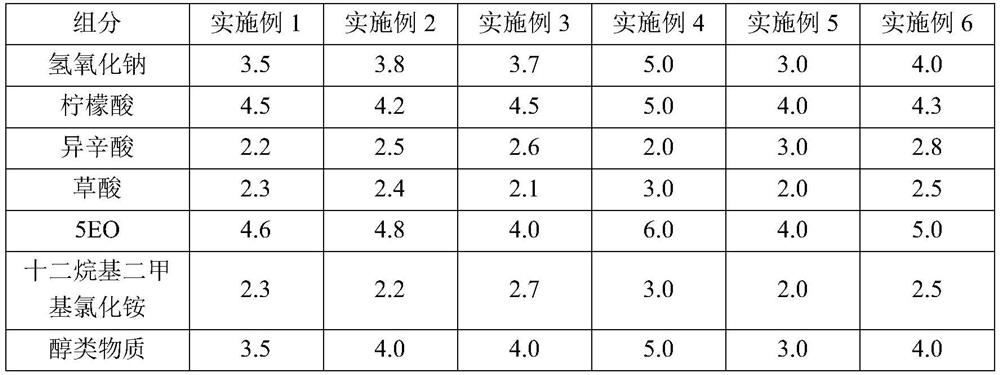

[0067] A cleaning agent for PET plastic plates, the difference from Example 1 is that the dosage of each component of the cleaning agent for PET plastic plates is different, see Table 1 for details.

[0068] Each group distribution ratio of table 1 embodiment 1-6

[0069]

Embodiment 7

[0071] A cleaning agent for PET plastic plates, consisting of the following components in percentage by weight:

[0072] Narrow molecular weight distribution Gubert alcohol polyoxyethylene ether (5EO) 4.8%;

[0073] Sodium hydroxide 3.8%;

[0074] Citric acid 4.2%;

[0075] Isooctanoic acid 2.5%;

[0076] Oxalic acid 2.4%;

[0077] Lauryl dimethyl ammonium chloride 2.2%;

[0078] Alcohols 4.0%;

[0079] Deionized water balance.

[0080] Wherein, the alcohol substance is a single component of isohexanediol.

[0081] The preparation method and usage method of the cleaning agent for PET plastic plates in this embodiment are the same as those in Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com