Pressure transmitter and assembling method thereof

A transmitter and pressure sensor technology, applied in the field of pressure transmitter and its assembly, can solve the problems of low quality, complex process, complex structure, etc., achieve stable and more durable electrical connection, avoid manual welding wires, and realize shielding signal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail below in conjunction with accompanying drawing:

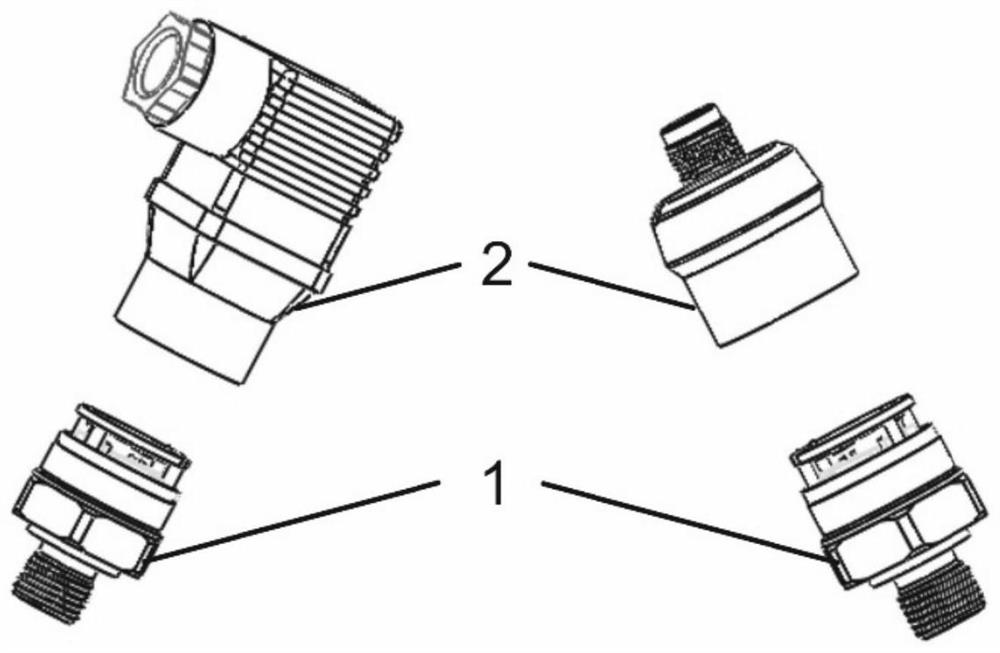

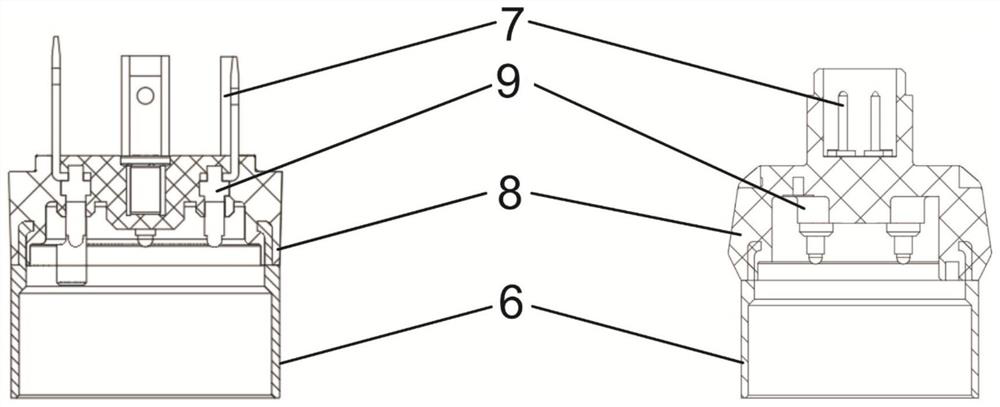

[0035] Such as figure 1 As shown, the present invention provides a pressure transmitter fully applicable to automatic production, which mainly includes two parts, Core module 1 and connector plug 2 . Modular design, the components that need to be configured according to the needs of customers are integrated into Core A components, and the rest of the standardized components are integrated into one, which solves the structural diversity caused by the diverse needs of customers and makes it impossible to carry out automated production. The design of all mechanisms has a positioning Card position structure, no wire connection, fully welded structure, can realize the structure manufacturing of automatic production and is suitable for use on the automatic production line of calibration.

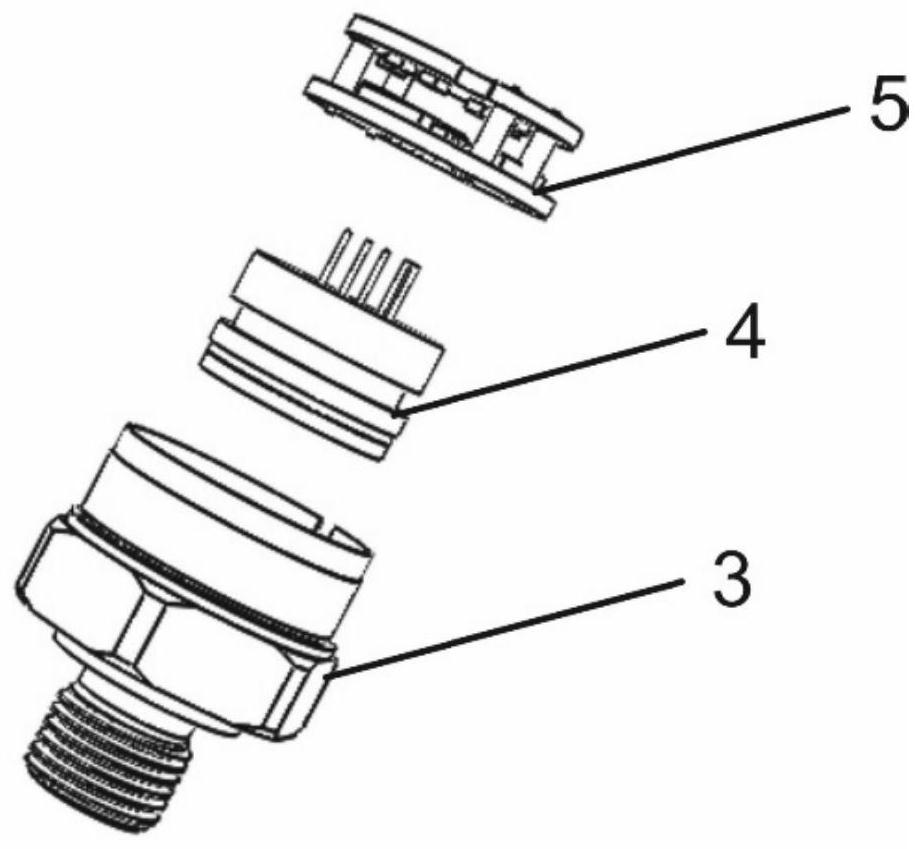

[0036] Core module 1 includes a base 3, a pressure sensor 4 and a PCB assembly 5 coax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com