LED pumping multi-wavelength waveguide laser and multi-wavelength waveguide laser

A waveguide laser and multi-wavelength technology, applied in lasers, laser components, phonon exciters, etc., can solve the problems of complex equipment and high manufacturing costs, achieve the effects of compensating optical loss, reducing manufacturing costs, and improving pumping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

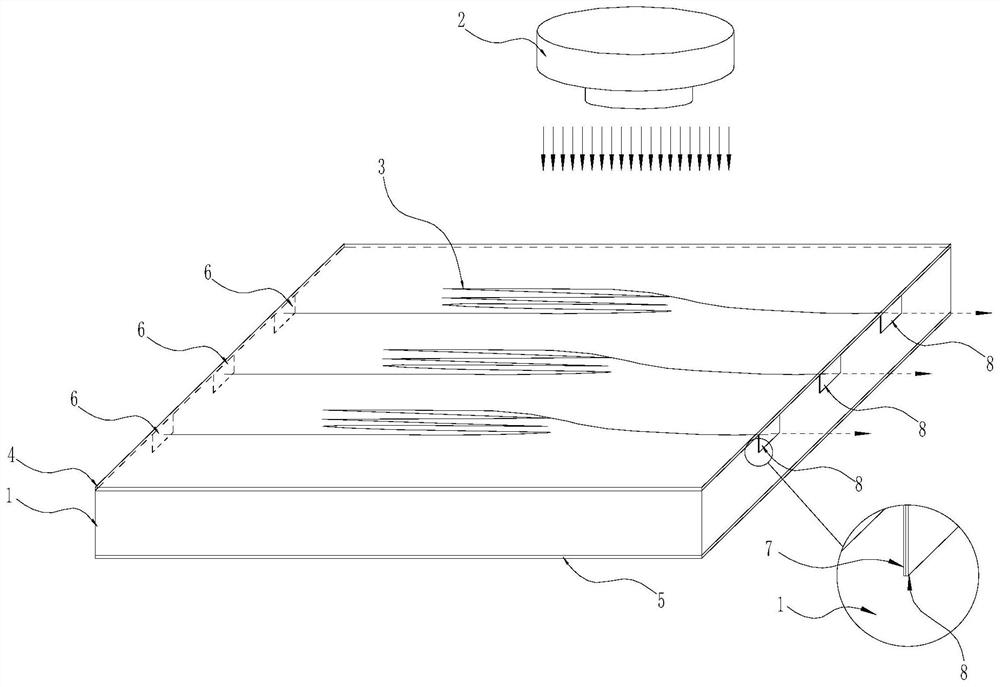

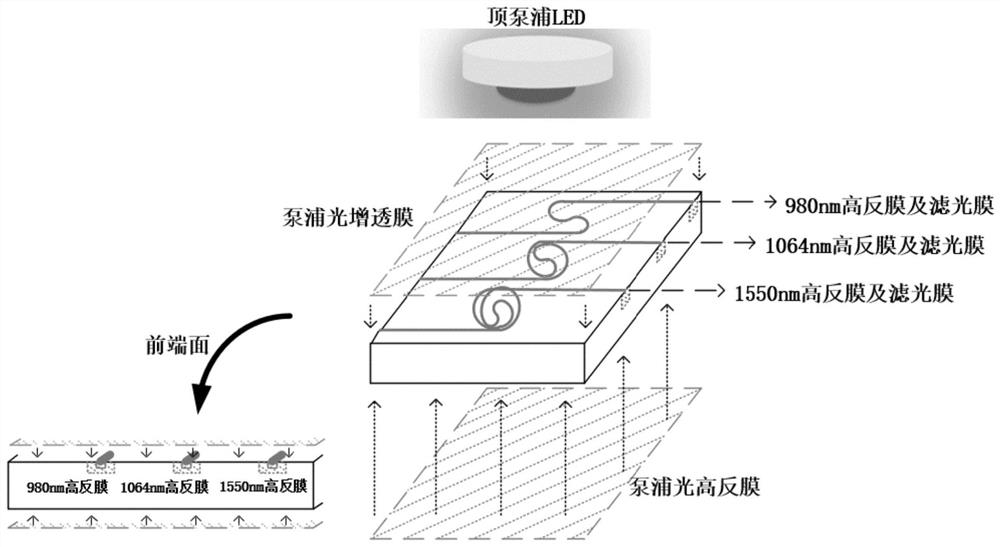

[0048] Such as figure 1 As shown, the present embodiment is an LED-pumped multi-wavelength waveguide laser, which includes: an optical substrate 1, an LED pump light source 2, a curved waveguide 3, a first anti-reflection film 4, a first high-reflection film 5, and a second high-reflection film. film 6, the third high reflection film 7 and filter film 8.

[0049] Wherein, the LED pumping light source 2 is used to provide laser pumping with a preset wavelength, and one end face of the optical base 1 is opposite to the output end of the LED pumping light source 2. In the solution of this embodiment, the optical base 1 The upper end surface is opposite to the output end of the LED pumping light source 2;

[0050] There are multiple curved waveguides 3, which are buried in the optical substrate 1 at intervals, one end of the multiple curved waveguides 3 extends to one side of the optical substrate 1, and the other end of the multiple curved waveguides 3 extends to the other side ...

Embodiment 2

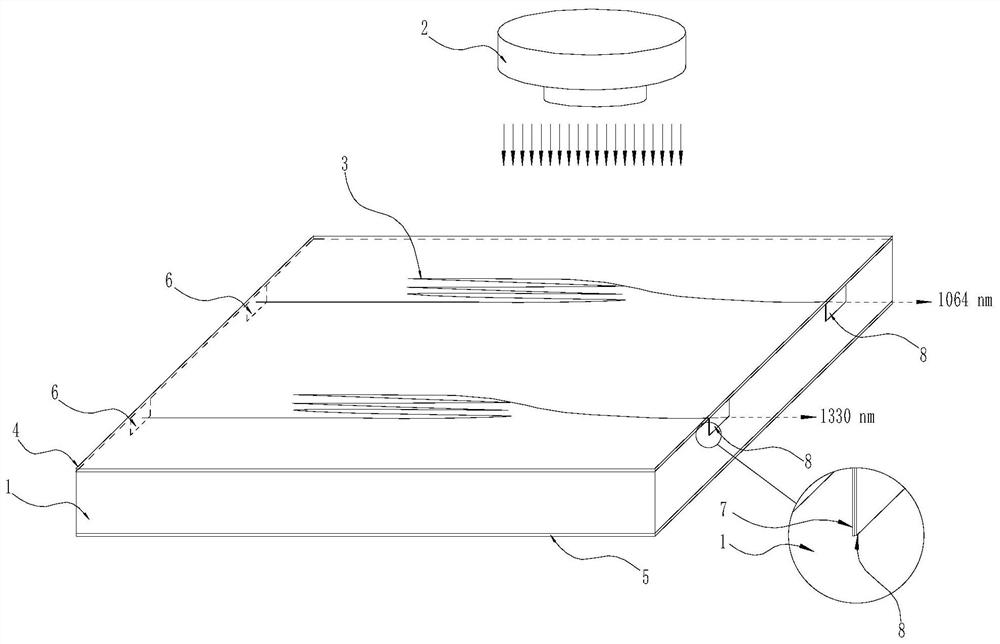

[0063] Such as image 3 As shown, the optical substrate 1, the LED pump light source 2, the curved waveguide 3, the first anti-reflection coating 4, the first high-reflection film 5, the second high-reflection film 6, the third high-reflection film 7 and the filter The structure of the optical film 8 is roughly the same as that of Embodiment 1, the difference is that the number of curved waveguides 3 in this embodiment is two, and the waveguide lasers in this embodiment are used to output 1064nm and 1330nm lasers.

[0064] In this embodiment, 1064nm and 1330nm co-emission waveguide lasers are produced, and glass doped with rare earth neodymium ions is selected to make buried curved waveguides. According to the absorption spectrum and absorption peak of glass doped with neodymium rare earth ions, 405nm, 581nm or 800nm LEDs can be selected as the top The pump light source is coated with a 405nm, 581nm or 800nm anti-reflection coating (i.e. the first anti-reflection coating) ...

Embodiment 3

[0068] This embodiment combines the two on the basis of Embodiment 1 and Embodiment 2, which includes two LED-pumped multi-wavelength waveguide lasers 1 relatively fixed by a substrate 2 .

[0069] In this solution, two LED-pumped multi-wavelength waveguide lasers 1 share the same LED pumping light source 3 .

[0070] This program produces 980nm, 1064nm, 1330nm, 1550nm common emission waveguide lasers. One of the lasers uses glass doped with erbium-ytterbium rare-earth ions as the optical substrate to make two buried curved waveguides, one of which is used to output 980nm laser, and the front and rear ends are coated with 980nm high-reflection film, and the reflectivity is greater than 95%. The reflectivity of the high-reflection film at the output end is less than 100%, and a filter film that only passes through 980nm is coated on the output end; the other waveguide is used to output 1550nm laser, and a high-reflection film of 1550nm is coated on the front and rear ends of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com